Hello everyone. I hope this is posted in the right place.

I recently purchased a Super Bronc on craigslist.

Before even trying to start it I replaced the carb and air filter.

I had to pull off the old rusted muffler, and the new one is in the mail.

I then drained the oil and refilled it, then filled the top gas tank.

She started up after a few pulls.

Here are my current issues.

First, i cant figure out how to stop the thing. I cant find a kill switch.

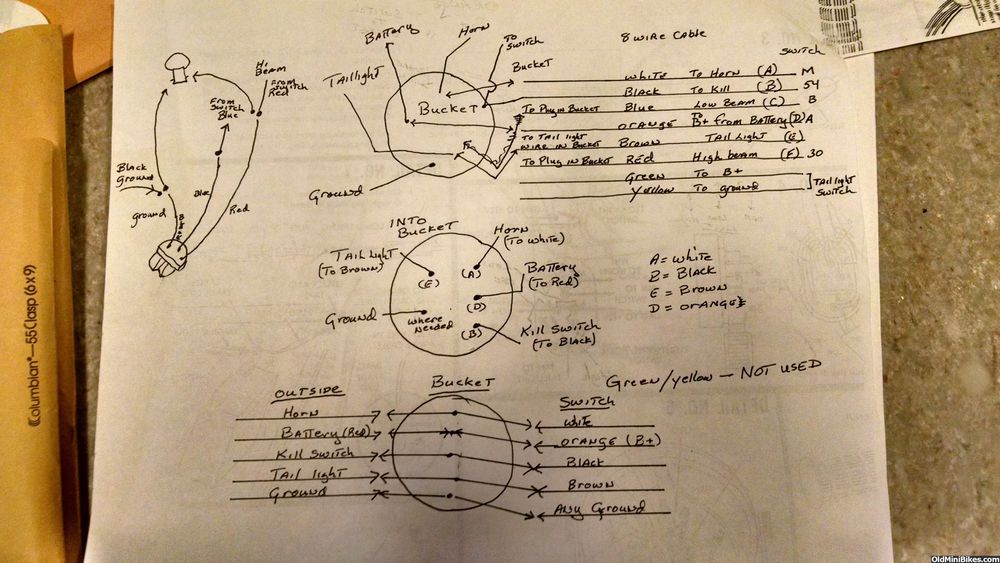

There is THIS on the left handlebar:

It looks like a blinker, but it has two other buttons on it. neither of them seem to kill the motor.

the bike eventually stops if you give it full throttle. probably have some mixture / choke tweaking to do to keep the thing going.

my second issue is the belt.

Im no expert, but this doesn't seem right.

I found this number on it: 203-026 DF

and I ordered one online.

Is the belt just old, is there some other way i am supposed to tighten it that I don't see?

thanks in advance for any help.

I recently purchased a Super Bronc on craigslist.

Before even trying to start it I replaced the carb and air filter.

I had to pull off the old rusted muffler, and the new one is in the mail.

I then drained the oil and refilled it, then filled the top gas tank.

She started up after a few pulls.

Here are my current issues.

First, i cant figure out how to stop the thing. I cant find a kill switch.

There is THIS on the left handlebar:

It looks like a blinker, but it has two other buttons on it. neither of them seem to kill the motor.

the bike eventually stops if you give it full throttle. probably have some mixture / choke tweaking to do to keep the thing going.

my second issue is the belt.

Im no expert, but this doesn't seem right.

I found this number on it: 203-026 DF

and I ordered one online.

Is the belt just old, is there some other way i am supposed to tighten it that I don't see?

thanks in advance for any help.