Let's go modeling! #1

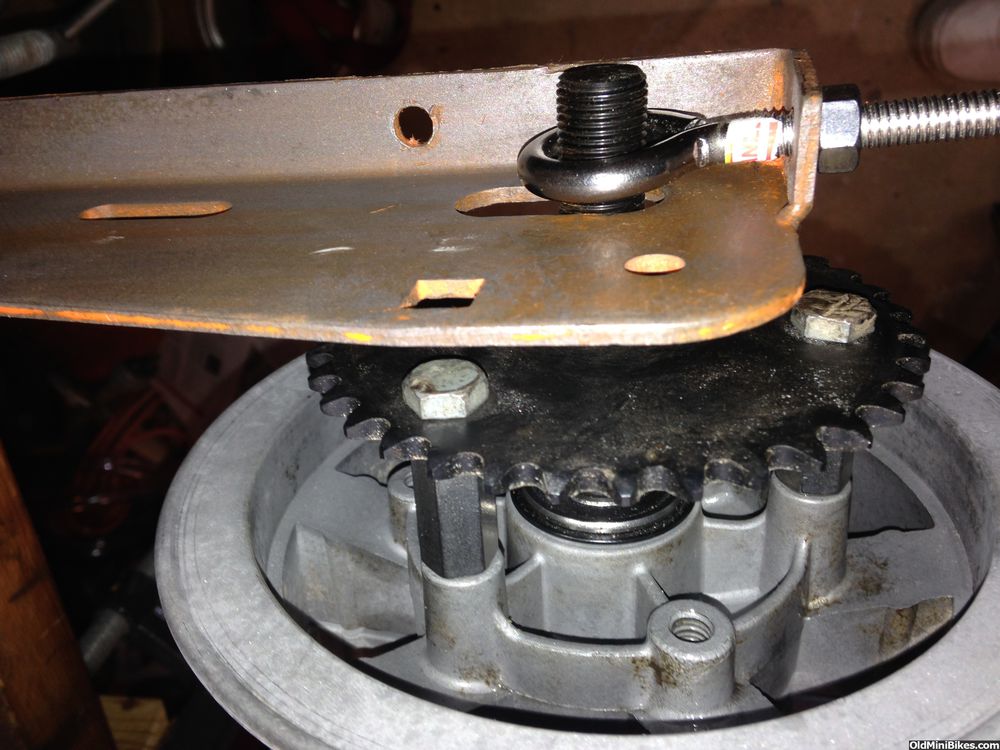

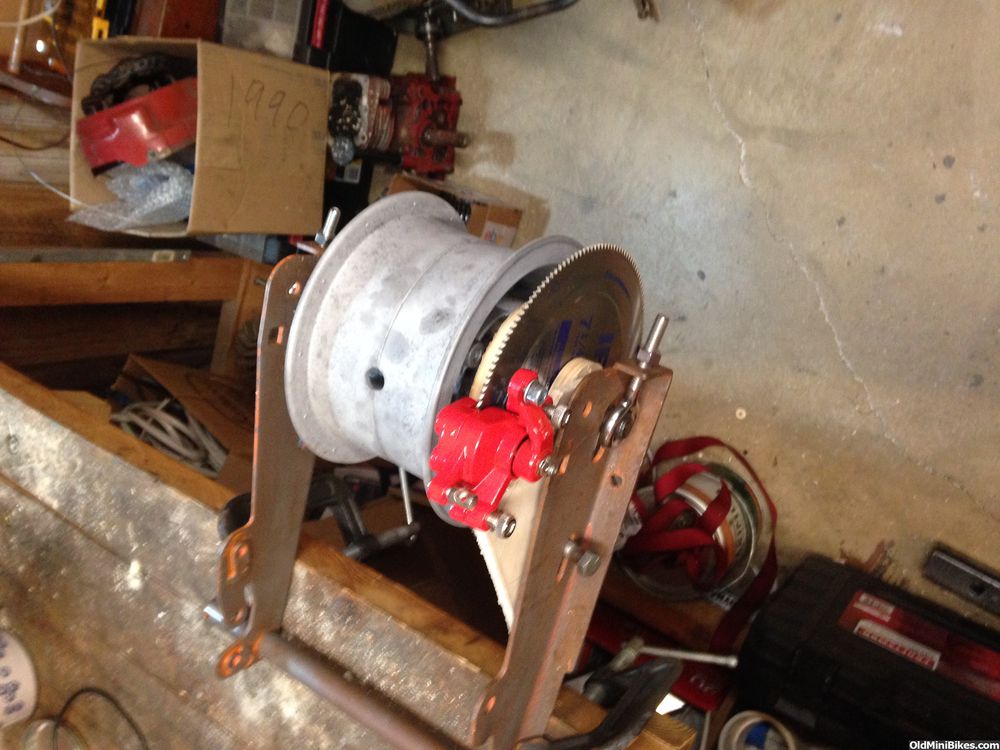

I'm going all out on this bike so it's getting disc brakes front and rear. Of course there's no disc hub that'll adapt to 1970s Bosch wheels, so they will have to be machined by a shop.

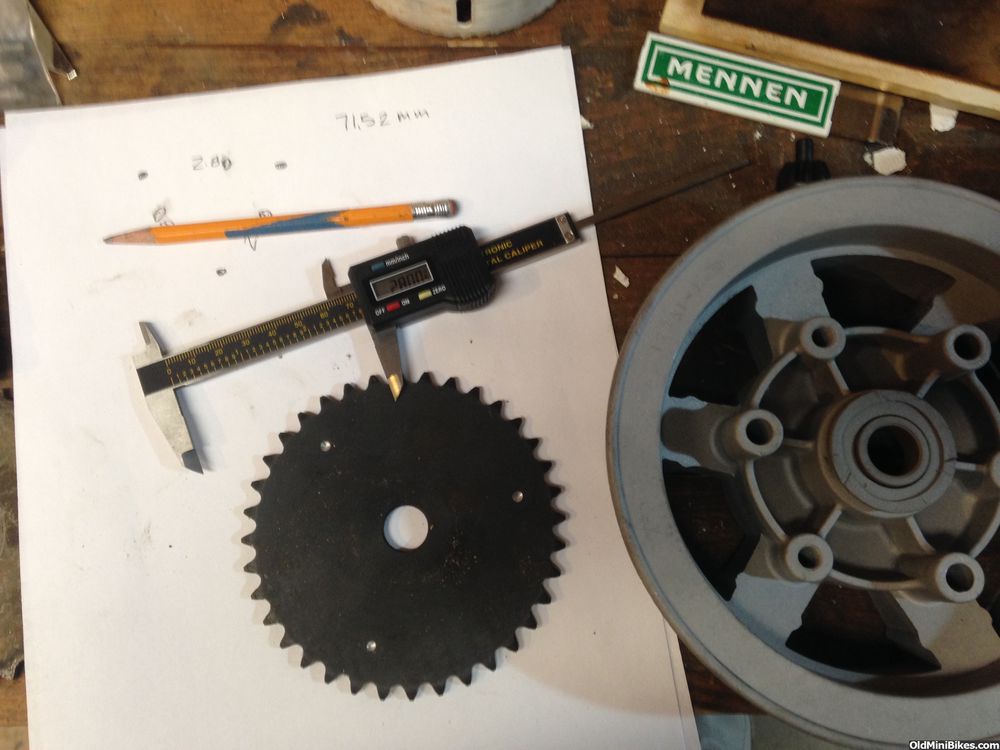

I needed to figure out the bolt circle so I could make the plate that'll mount to the wheel. I found 36 tooth blank sprockets at Gamut (a division of Graniger), and I had a pretty worn out original. To get the proper pattern so I could measure it, I put the new sprocket on the bench and used 3- #10 sheet metal screws to lock the OG sprocket to the new one. I had to use the bottom diameter of the sprocket (see below) to secure.

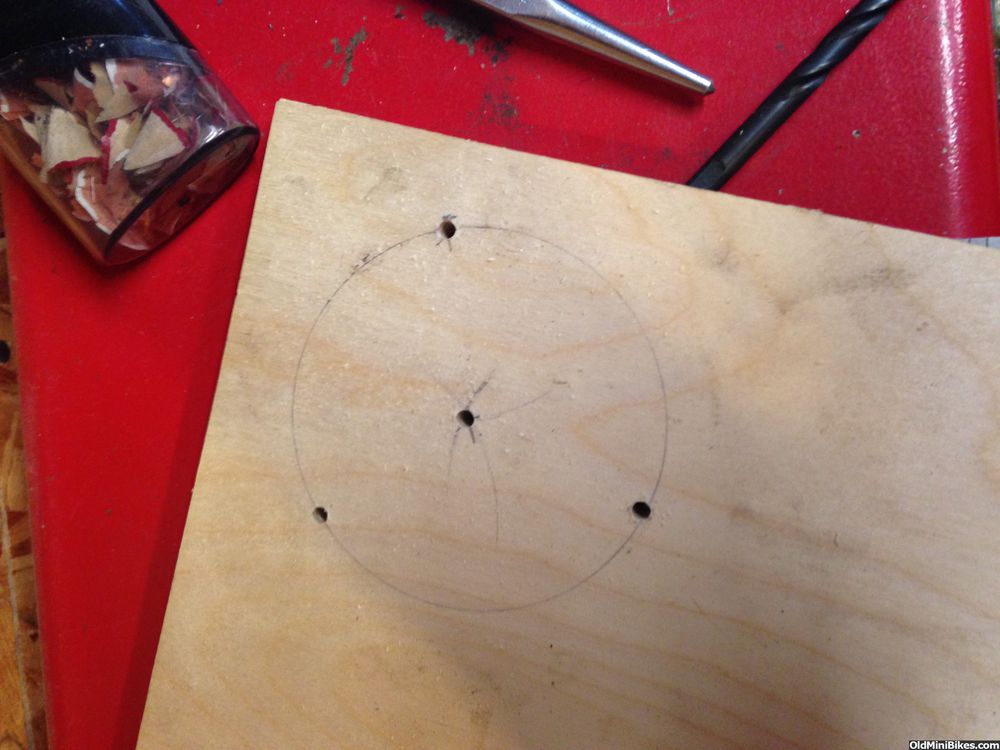

I used a 5/16" bit to locate the hole centers.

Here's a hint: Often you'll get an optical illusion that makes the mating pieces look like they are not lined up properly. I used the gridlines in my phone's camera to check my work as they help with any eyeballing necessary.

I drilled 3/16" holes in the sprocket and then used a punch to mark the bolt circle on card stock. I used my caliper to measure the distances between hole centerlines, checked against both the wheel and the original sprocket--2.80"

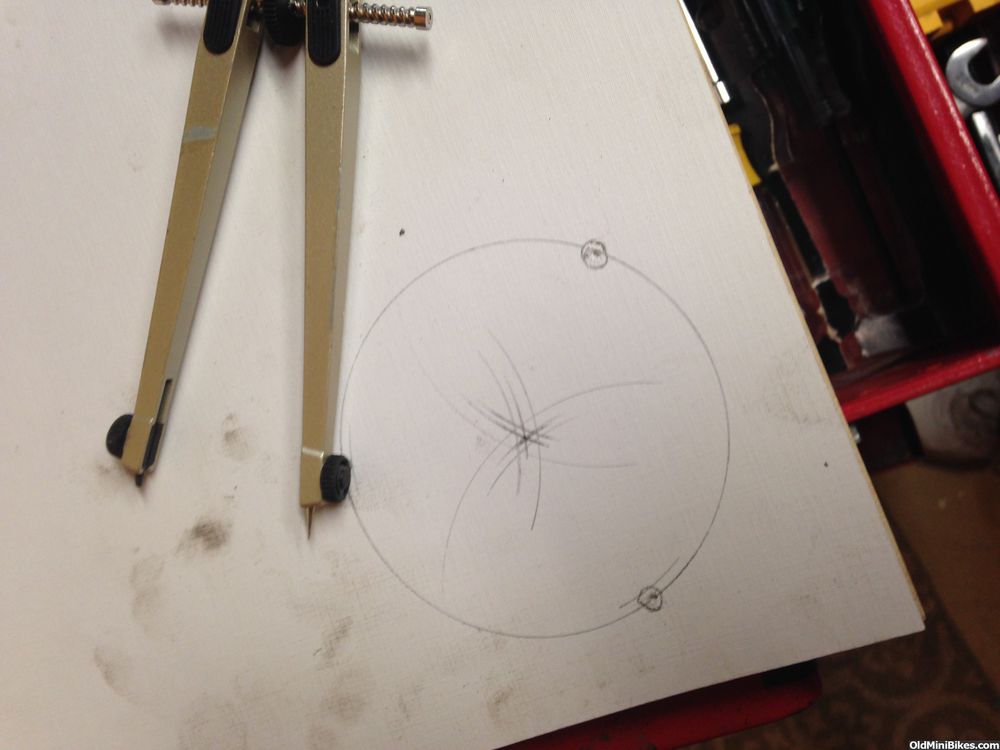

I used a compass to locate the center of the bolt circle--all trial and error until I found the sweet spot. This gave me a template to use when I do a CAD drawing of the part.