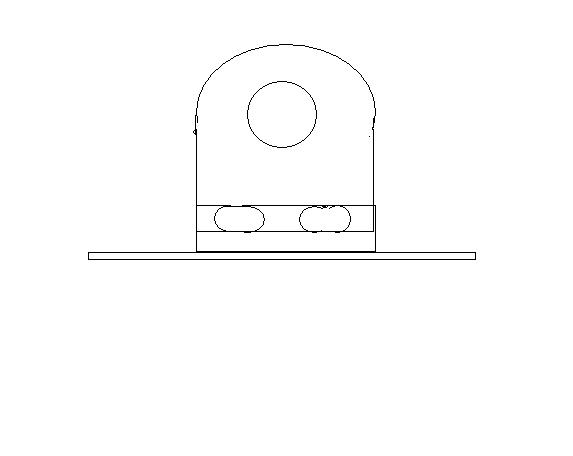

Ok so the paint dried enough to throw the motor into the frame and visualy see how its going to line up with the sprocket. Its going to be too close even when I install the spacer I ordered to lift the engine over the frame rail that prevents the blower housing from moving far enough over currently. I think what I'm going to have to do is put a jack shaft in and turn the wheel around. I think this is how the bike probably was meant to be configured in the first place. Then someone put the foot brake on what appears to have been jack shaft mounts anyway. So I'm thinking I'll take the footbrake out and installing a jackshaft there. But what size holes would need to be there for bearings? Are these brackets thick enough to hold bearings? It looks like the holes would need to be much bigger too. Basically before I go down this time consuming and I'm sure frustrating road, can anyone who has done this before tell me if it looks like it can be done. I'm sure there are issues I have not thought of. Thanks