Nitro 44 or 50 drag bike...

- Thread starter BamAss5150

- Start date

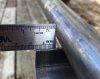

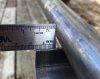

Personally, I will never buy anything from Minichoppersocal or 909 Minibikes ever again, Here's why. Last year I ordered a Nitro 44 frame kit, when it arrived the first thing I noticed when taking it out of the box was that the engine plate wasn't welded straight, that was just the beginning. I measured the difference forward and aft and there was about an 7mm difference between the two. Then I noticed the welds weren't complete on the axle eyelets and the forks wouldn't fit without first turning them to one side and then hitting them with a rubber mallet just to get them to go on. The seat bracket wasn't straight either, it was like it was made on a Friday night after about a twelve pack or so. I called their number and spoke with whom I believe was the owner and he was very nice but that doesn't account for sending out a terrible product. I told him of the crooked motor mount and he said that it may appear crooked on the frame loop but he assured me that it was straight with the axle hangers and to install the axle and check again.

He also noted that his frame jigs are checked regularly and his tolerances are 1/16" where as the industry standard is 1/4". Funny he should say that because I just happened to have laser crosshairs. I also noticed that there were no holes drilled in any of the tubing, this is necessary when you weld any tubing closed to prevent the gases building up and either blowing out the weld or even worse, the tubing seam. He informed me that he has been doing this for thirty years and I was the first person who has complained about the quality of welds and that he doesn't drill holes in his frames and told me "That must be an east coast thing". You would think that someone who does this for a living would understand welding basics as this was the first lesson I learned from my welding buddy ( who is certified ). Here's a quote from The Welders Handbook "Drill a relief hole in the tubing that's being welded closed. If you don't, air pressure building up from the heat inside the tube will blow out the last of your weld as you finish sealing up the tube.". He did say I could return the frame but he never mentioned to who's expense. He then told me that a TIG welded frame would cost me over $1,000.00, I thought to myself, shouldn't I get a frame that was welded correctly regardless of price?. No story should go without proof so attached are some pictures, the proof is in the pudding.

The first two pictures show the measurements forward and aft, the third is of an incomplete weld, the fourth is of a crooked seat bracket, the fifth and sixth are of my laser crosshairs in the keyway of the tightened axle also centered on the setscrews, the seventh is of how far off the motor mount holes are off from the laser line tool ( notice the laser is on the inside of the bottom hole and almost the outside of the top hole ), the eighth picture is of a blown out weld from not drilling holes in your tubing before welding it closed. I thought that made in U.S.A. meant something and was a big reason for me to purchase this frame but apparently some kid in China can weld better than this guy with over thirty years experience, not to mention the whole " east coast " remark. So if you live on the west coast, maybe the welds won't fail or maybe it won't throw chains with it's crooked motor mount but hey, with the crooked seat bracket, you'll feel as if you're going straight!.

He also noted that his frame jigs are checked regularly and his tolerances are 1/16" where as the industry standard is 1/4". Funny he should say that because I just happened to have laser crosshairs. I also noticed that there were no holes drilled in any of the tubing, this is necessary when you weld any tubing closed to prevent the gases building up and either blowing out the weld or even worse, the tubing seam. He informed me that he has been doing this for thirty years and I was the first person who has complained about the quality of welds and that he doesn't drill holes in his frames and told me "That must be an east coast thing". You would think that someone who does this for a living would understand welding basics as this was the first lesson I learned from my welding buddy ( who is certified ). Here's a quote from The Welders Handbook "Drill a relief hole in the tubing that's being welded closed. If you don't, air pressure building up from the heat inside the tube will blow out the last of your weld as you finish sealing up the tube.". He did say I could return the frame but he never mentioned to who's expense. He then told me that a TIG welded frame would cost me over $1,000.00, I thought to myself, shouldn't I get a frame that was welded correctly regardless of price?. No story should go without proof so attached are some pictures, the proof is in the pudding.

The first two pictures show the measurements forward and aft, the third is of an incomplete weld, the fourth is of a crooked seat bracket, the fifth and sixth are of my laser crosshairs in the keyway of the tightened axle also centered on the setscrews, the seventh is of how far off the motor mount holes are off from the laser line tool ( notice the laser is on the inside of the bottom hole and almost the outside of the top hole ), the eighth picture is of a blown out weld from not drilling holes in your tubing before welding it closed. I thought that made in U.S.A. meant something and was a big reason for me to purchase this frame but apparently some kid in China can weld better than this guy with over thirty years experience, not to mention the whole " east coast " remark. So if you live on the west coast, maybe the welds won't fail or maybe it won't throw chains with it's crooked motor mount but hey, with the crooked seat bracket, you'll feel as if you're going straight!.

you might wanna try https://fbminibikes.com/

Personally, I will never buy anything from Minichoppersocal or 909 Minibikes ever again, Here's why. Last year I ordered a Nitro 44 frame kit, when it arrived the first thing I noticed when taking it out of the box was that the engine plate wasn't welded straight, that was just the beginning. I measured the difference forward and aft and there was about an 7mm difference between the two. Then I noticed the welds weren't complete on the axle eyelets and the forks wouldn't fit without first turning them to one side and then hitting them with a rubber mallet just to get them to go on. The seat bracket wasn't straight either, it was like it was made on a Friday night after about a twelve pack or so. I called their number and spoke with whom I believe was the owner and he was very nice but that doesn't account for sending out a terrible product. I told him of the crooked motor mount and he said that it may appear crooked on the frame loop but he assured me that it was straight with the axle hangers and to install the axle and check again.

He also noted that his frame jigs are checked regularly and his tolerances are 1/16" where as the industry standard is 1/4". Funny he should say that because I just happened to have laser crosshairs. I also noticed that there were no holes drilled in any of the tubing, this is necessary when you weld any tubing closed to prevent the gases building up and either blowing out the weld or even worse, the tubing seam. He informed me that he has been doing this for thirty years and I was the first person who has complained about the quality of welds and that he doesn't drill holes in his frames and told me "That must be an east coast thing". You would think that someone who does this for a living would understand welding basics as this was the first lesson I learned from my welding buddy ( who is certified ). Here's a quote from The Welders Handbook "Drill a relief hole in the tubing that's being welded closed. If you don't, air pressure building up from the heat inside the tube will blow out the last of your weld as you finish sealing up the tube.". He did say I could return the frame but he never mentioned to who's expense. He then told me that a TIG welded frame would cost me over $1,000.00, I thought to myself, shouldn't I get a frame that was welded correctly regardless of price?. No story should go without proof so attached are some pictures, the proof is in the pudding.

The first two pictures show the measurements forward and aft, the third is of an incomplete weld, the fourth is of a crooked seat bracket, the fifth and sixth are of my laser crosshairs in the keyway of the tightened axle also centered on the setscrews, the seventh is of how far off the motor mount holes are off from the laser line tool ( notice the laser is on the inside of the bottom hole and almost the outside of the top hole ), the eighth picture is of a blown out weld from not drilling holes in your tubing before welding it closed. I thought that made in U.S.A. meant something and was a big reason for me to purchase this frame but apparently some kid in China can weld better than this guy with over thirty years experience, not to mention the whole " east coast " remark. So if you live on the west coast, maybe the welds won't fail or maybe it won't throw chains with it's crooked motor mount but hey, with the crooked seat bracket, you'll feel as if you're going straight!.

View attachment 241837 View attachment 241838 View attachment 241839 View attachment 241840 View attachment 241841 View attachment 241848 View attachment 241849 View attachment 241851

He also noted that his frame jigs are checked regularly and his tolerances are 1/16" where as the industry standard is 1/4". Funny he should say that because I just happened to have laser crosshairs. I also noticed that there were no holes drilled in any of the tubing, this is necessary when you weld any tubing closed to prevent the gases building up and either blowing out the weld or even worse, the tubing seam. He informed me that he has been doing this for thirty years and I was the first person who has complained about the quality of welds and that he doesn't drill holes in his frames and told me "That must be an east coast thing". You would think that someone who does this for a living would understand welding basics as this was the first lesson I learned from my welding buddy ( who is certified ). Here's a quote from The Welders Handbook "Drill a relief hole in the tubing that's being welded closed. If you don't, air pressure building up from the heat inside the tube will blow out the last of your weld as you finish sealing up the tube.". He did say I could return the frame but he never mentioned to who's expense. He then told me that a TIG welded frame would cost me over $1,000.00, I thought to myself, shouldn't I get a frame that was welded correctly regardless of price?. No story should go without proof so attached are some pictures, the proof is in the pudding.

The first two pictures show the measurements forward and aft, the third is of an incomplete weld, the fourth is of a crooked seat bracket, the fifth and sixth are of my laser crosshairs in the keyway of the tightened axle also centered on the setscrews, the seventh is of how far off the motor mount holes are off from the laser line tool ( notice the laser is on the inside of the bottom hole and almost the outside of the top hole ), the eighth picture is of a blown out weld from not drilling holes in your tubing before welding it closed. I thought that made in U.S.A. meant something and was a big reason for me to purchase this frame but apparently some kid in China can weld better than this guy with over thirty years experience, not to mention the whole " east coast " remark. So if you live on the west coast, maybe the welds won't fail or maybe it won't throw chains with it's crooked motor mount but hey, with the crooked seat bracket, you'll feel as if you're going straight!.

View attachment 241837 View attachment 241838 View attachment 241839 View attachment 241840 View attachment 241841 View attachment 241848 View attachment 241849 View attachment 241851

Sheeeesh that sucks bro im sorry you had to deal with that mess but me personally never had a problem with them parts a lil pricy for simple stuff but other then that i like...but no lie after i seen your pics i went nd checked all the weld i maybe spotted two possible fault welds but other then that everything else seem fine,hopefully with me stayin in vegas the weld wont break but ima be honest ive had some crazy applications on here before my accident nd the thing still never cracked under stress...were did you get the anodized axle from??? And if have any lyin around parts inbox me yeah...Seat,gas tank (etc)

Attachments

-

2.2 MB Views: 12

-

1.8 MB Views: 11

-

2.8 MB Views: 10

-

1.5 MB Views: 9

-

1.7 MB Views: 9

you might wanna try https://fbminibikes.com/

Maybe he just sends the bad ones to the east coast, hahaha. Yours appears to be a little different than mine, maybe the old style?. My axle is the stock black one that came with the roller kit, my laser line tool may be affecting it's appearance in the picture. I still don't know what I'm going to do with this thing, I may cut and grind all the welds and re-do them. What really sucks is all the nice red anodized parts I bought to go with it, bearing cartridges, front and rear wheel hubs, brake hub, CNC throttle and hydraulic brake lever, steering stabilizer, you name it, this was going to be a nice drag bike. I also have a 18-20HP clone that was going to go on it, I was going to do a whole build thread but I don't want to give people the impression that they're going to receive a good product after this.

Lol im dead...yeah definitely your laser...and yeah this was the older nitro 44 frame its i got it back when like nobody knew bout 909SCMB i truthfully stumbled upon tht place seen the frame paid $800 that day period...honestly brotha i would keep it i mean you spent $1k so imean what harm can it do to break the weld and reweld em to your likings then its just not a pile of pos just sittin there ya know...but cmon be a guy and put me on with the anodized parts (blue) lol...and where you thinking gettin the stabilizer from cause yeah anything over 50 it get mad wobbly i had one from a super pocketbike but lost it movin...Honestly like i said i haven’t had a problem with my frame after the years ive added welds cut weld grinded them down back to original and its still held strong...the prices are a lil outlandish but i wouldn’t give em a bad rep tho jmo

If I can say one nice thing is that the tubing and bends are great, if it wasn't for the sloppy out the door attitude, I would have a little more confidence in it. I planned on running a 40mm axle with a go cart wheel hub and sprocket and brake hubs, I think they do have them in blue too!. The hubs and cartridges are for a Bintelli go cart, the only thing is you would have to have an axle made for it. I got the steering stabilizer on eBay as well as the hydraulic brake lever, you know how hard it is to find a CNC hydraulic brake lever for the left side?, pretty hard for the correct one anyhow. I also got a nice Brembo clone CNC caliper for it as well, Like I said, it was going to be top notch. I'll get back to it one day but have to cure the steering tube of it's faults as well. the newer frames use bearings with the clips and no washers in-between the triple-tree plates and bearings, made for to tight of a fit on mine, not to mention the bearings outside diameter is smaller than the steer tubes inner diameter making for a lot of steering slop.

If I can say one nice thing is that the tubing and bends are great, if it wasn't for the sloppy out the door attitude, I would have a little more confidence in it. I planned on running a 40mm axle with a go cart wheel hub and sprocket and brake hubs, I think they do have them in blue too!. The hubs and cartridges are for a Bintelli go cart, the only thing is you would have to have an axle made for it. I got the steering stabilizer on eBay as well as the hydraulic brake lever, you know how hard it is to find a CNC hydraulic brake lever for the left side?, pretty hard for the correct one anyhow. I also got a nice Brembo clone CNC caliper for it as well, Like I said, it was going to be top notch. I'll get back to it one day but have to cure the steering tube of it's faults as well. the newer frames use bearings with the clips and no washers in-between the triple-tree plates and bearings, made for to tight of a fit on mine, not to mention the bearings outside diameter is smaller than the steer tubes inner diameter making for a lot of steering slop.