I wanted a go-kart, but I also had a dirt bike rolling frame sitting around from an earlier project. So why not both?

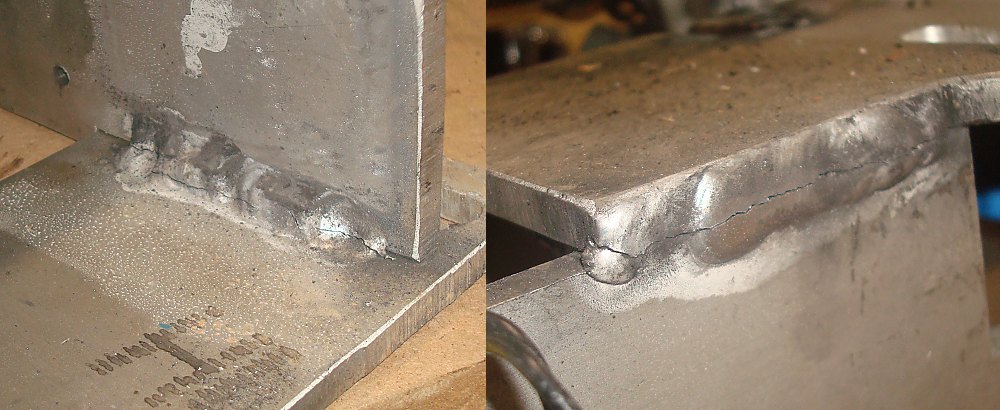

Photos are in chronological order. The beginning of the build saw a lot of part improvisation, including a pool vacuum hose intake line.

http://www.captainslug.com/temp/vlad_002.jpg

http://www.captainslug.com/temp/vlad_003.jpg

http://www.captainslug.com/temp/vlad_005.jpg

http://www.captainslug.com/temp/vlad_007.jpg

http://www.captainslug.com/temp/vlad_008.jpg

http://www.captainslug.com/temp/vlad_009.jpg

http://www.captainslug.com/temp/vlad_010.jpg

http://www.captainslug.com/temp/vlad_011.jpg

http://www.captainslug.com/temp/vlad_013.jpg

http://www.captainslug.com/temp/vlad_014.jpg

http://www.captainslug.com/temp/vlad_016.jpg

http://www.captainslug.com/temp/vlad_017.jpg

http://www.captainslug.com/temp/vlad_018.jpg

http://www.captainslug.com/temp/vlad_019.jpg

http://www.captainslug.com/temp/vlad_021.jpg

http://www.captainslug.com/temp/vlad_022.jpg

http://www.captainslug.com/temp/vlad_023.jpg

http://www.captainslug.com/temp/vlad_024.jpg

http://www.captainslug.com/temp/vlad_025.jpg

http://www.captainslug.com/temp/vlad_026.jpg

http://www.captainslug.com/temp/vlad_028.jpg

http://www.captainslug.com/temp/vlad_029.jpg

http://www.captainslug.com/temp/vlad_030.jpg

http://www.captainslug.com/temp/vlad_031.jpg

http://www.captainslug.com/temp/vlad_032.jpg

http://www.captainslug.com/temp/vlad_033.jpg

http://www.captainslug.com/temp/vlad_034.jpg

http://www.captainslug.com/temp/vlad_035.jpg

http://www.captainslug.com/temp/vlad_036.jpg

http://www.captainslug.com/temp/vlad_037.jpg

http://www.captainslug.com/temp/vlad_038.jpg

http://www.captainslug.com/temp/vlad_039.jpg

http://www.captainslug.com/temp/vlad_041.jpg

http://www.captainslug.com/temp/vlad_042.jpg

http://www.captainslug.com/temp/vlad_043.jpg

http://www.captainslug.com/temp/vlad_044.jpg

http://www.captainslug.com/temp/vlad_045.jpg

http://www.captainslug.com/temp/vlad_046.jpg

http://www.captainslug.com/temp/vlad_047.jpg

http://www.captainslug.com/temp/vlad_048.jpg

http://www.captainslug.com/temp/vlad_050.jpg

This project took 2 months of work in the summer of 2012 to get running. I've worked on it one weekend a month for the past year.

I took it to a small car show 2 months after I finished it and placed in the Top 10 out of 40 motorcycles.

Photos are in chronological order. The beginning of the build saw a lot of part improvisation, including a pool vacuum hose intake line.

http://www.captainslug.com/temp/vlad_002.jpg

http://www.captainslug.com/temp/vlad_003.jpg

http://www.captainslug.com/temp/vlad_005.jpg

http://www.captainslug.com/temp/vlad_007.jpg

http://www.captainslug.com/temp/vlad_008.jpg

http://www.captainslug.com/temp/vlad_009.jpg

http://www.captainslug.com/temp/vlad_010.jpg

http://www.captainslug.com/temp/vlad_011.jpg

http://www.captainslug.com/temp/vlad_013.jpg

http://www.captainslug.com/temp/vlad_014.jpg

http://www.captainslug.com/temp/vlad_016.jpg

http://www.captainslug.com/temp/vlad_017.jpg

http://www.captainslug.com/temp/vlad_018.jpg

http://www.captainslug.com/temp/vlad_019.jpg

http://www.captainslug.com/temp/vlad_021.jpg

http://www.captainslug.com/temp/vlad_022.jpg

http://www.captainslug.com/temp/vlad_023.jpg

http://www.captainslug.com/temp/vlad_024.jpg

http://www.captainslug.com/temp/vlad_025.jpg

http://www.captainslug.com/temp/vlad_026.jpg

http://www.captainslug.com/temp/vlad_028.jpg

http://www.captainslug.com/temp/vlad_029.jpg

http://www.captainslug.com/temp/vlad_030.jpg

http://www.captainslug.com/temp/vlad_031.jpg

http://www.captainslug.com/temp/vlad_032.jpg

http://www.captainslug.com/temp/vlad_033.jpg

http://www.captainslug.com/temp/vlad_034.jpg

http://www.captainslug.com/temp/vlad_035.jpg

http://www.captainslug.com/temp/vlad_036.jpg

http://www.captainslug.com/temp/vlad_037.jpg

http://www.captainslug.com/temp/vlad_038.jpg

http://www.captainslug.com/temp/vlad_039.jpg

http://www.captainslug.com/temp/vlad_041.jpg

http://www.captainslug.com/temp/vlad_042.jpg

http://www.captainslug.com/temp/vlad_043.jpg

http://www.captainslug.com/temp/vlad_044.jpg

http://www.captainslug.com/temp/vlad_045.jpg

http://www.captainslug.com/temp/vlad_046.jpg

http://www.captainslug.com/temp/vlad_047.jpg

http://www.captainslug.com/temp/vlad_048.jpg

http://www.captainslug.com/temp/vlad_050.jpg

This project took 2 months of work in the summer of 2012 to get running. I've worked on it one weekend a month for the past year.

- The top speed is 45mph.

- Wet Weight is 180lb.

- The fender\headlight is made out of 22ga stainless steel that I cut and welded together.

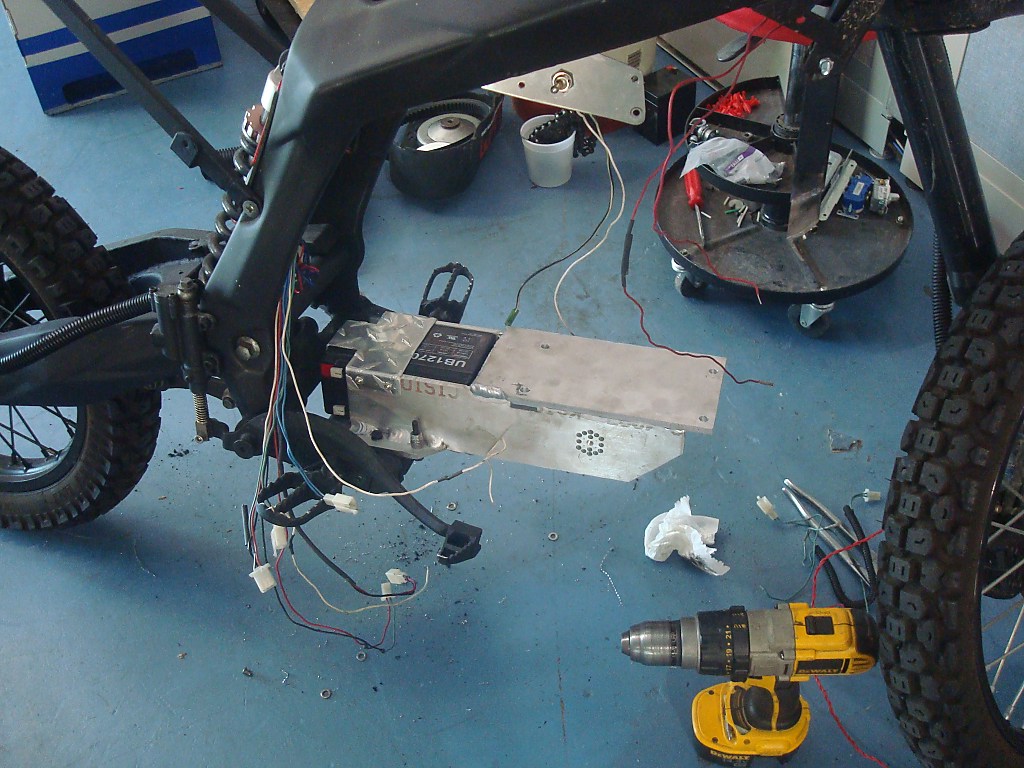

- The frame is from an X-Motos XB-31 (Chinestraulian Honda knockoff)

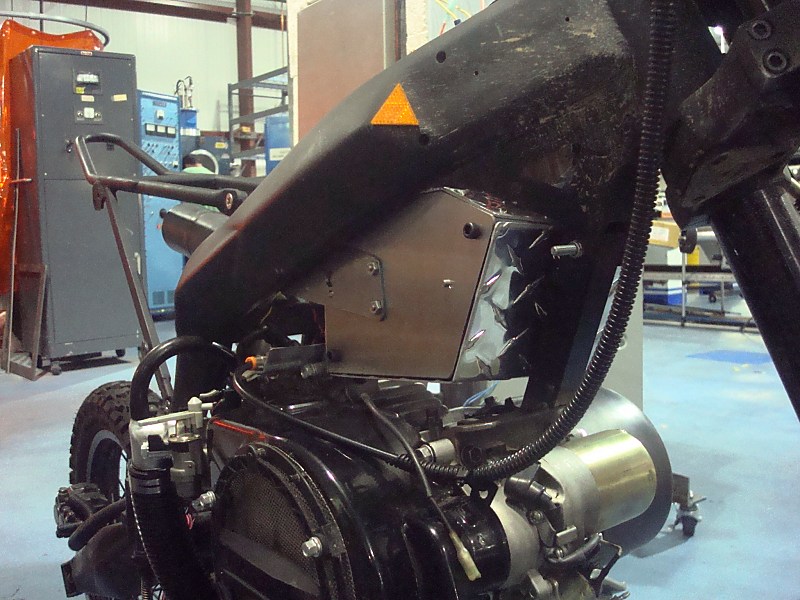

- The motor is a 196cc LiFan clone of the Honda GX200 with electric start. I haven't removed the governor on it yet.

- Primary reduction is a TAV2 Torq-a-verter CVT

- 11-inch clearance mini bike header from OldMiniBikes Warehouse w/ a Briggs & Stratton muffler.

- The electrical system was added from scratch.

- The air cleaner had to be moved and reoriented so I made a hose adapter for the carb.

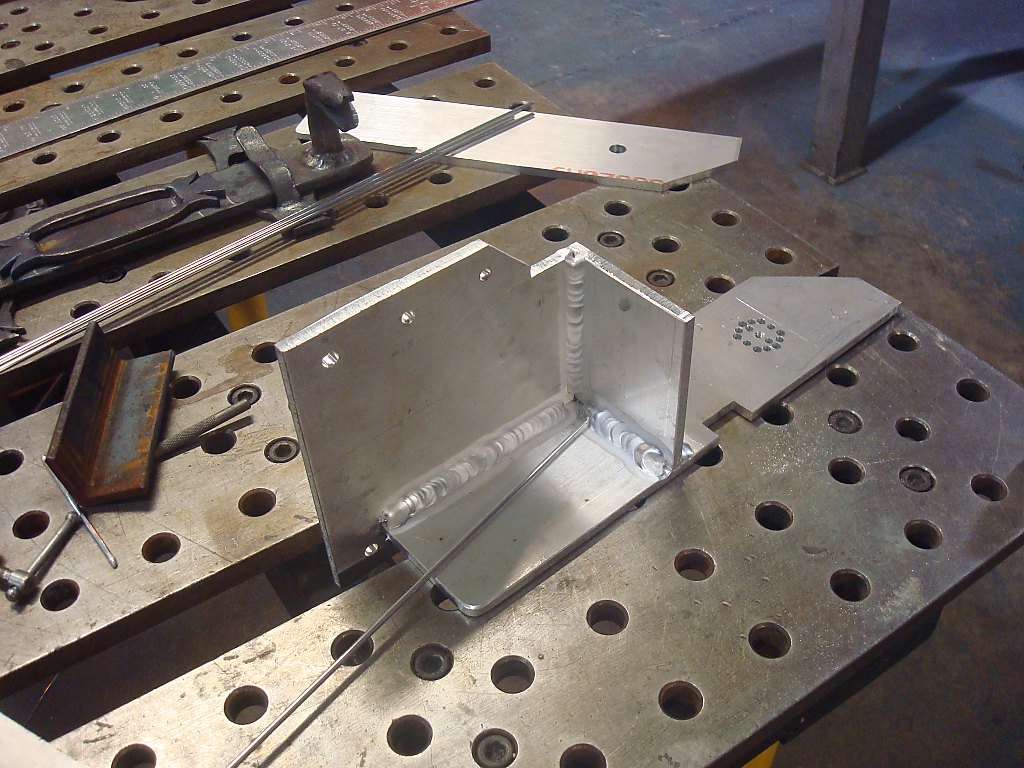

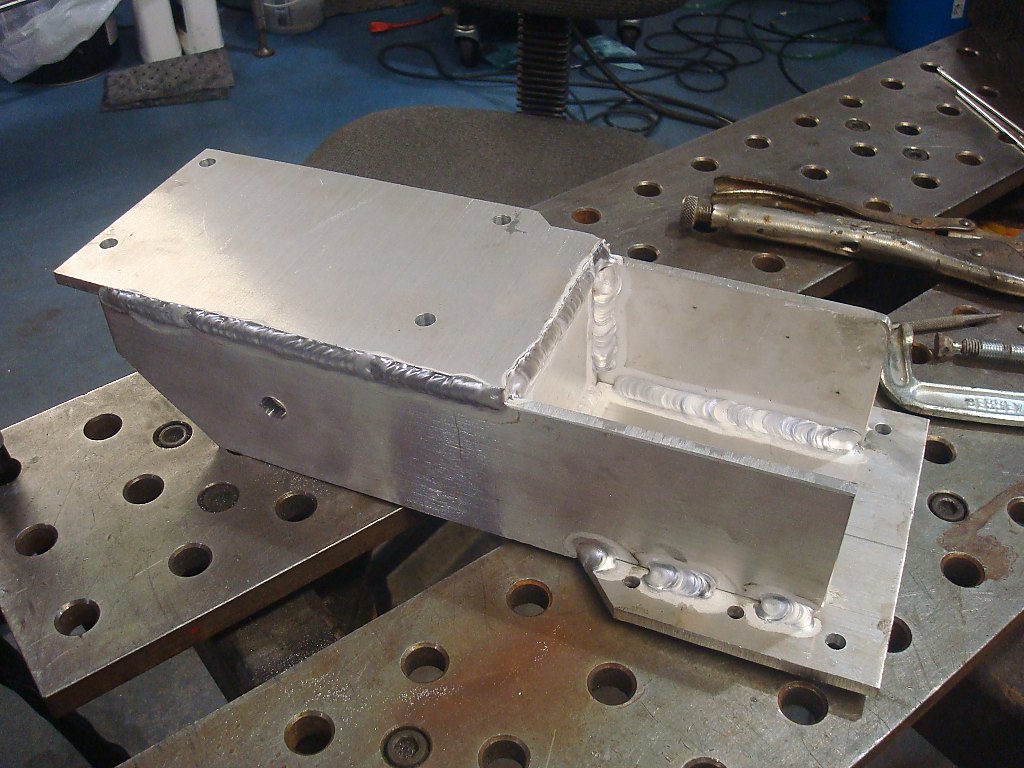

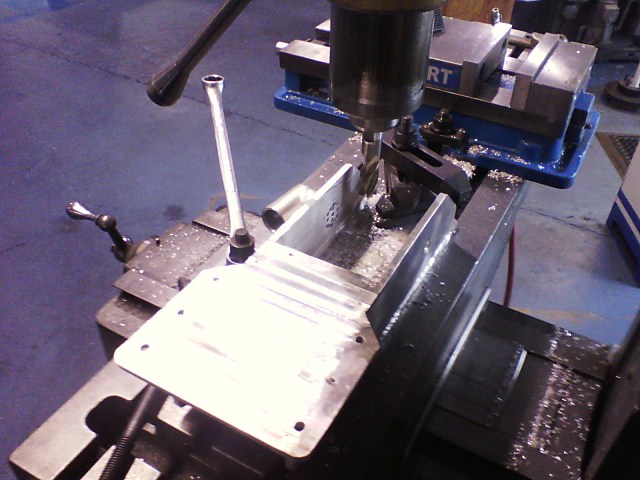

- The aluminum motor mount was made from scratch and double as an enclosure for the electrical system which is all DIN-rail mount components.

- The downtube adapter is from scratch

- The most recent pictures show that I went from having a chain tensioner to redoing all of the rear wheel adjustment components.

- The rear sprocket was milled out to match the rear hub bolt pattern and to reduce weight. It's the only custom part on the bike that I didn't make myself

- The fan cover which replaced the old recoil start cover was 3D printed.

- The push-button switch shown on the bracket above the fan housing that holds the air cleaner is the hidden push-button start.

- Aluminum clip-on handlebars are from scratch. The core of them is a 5-inch long 1/2-13 bolt.

- Speedometer is a cheap $35 GPS unit.

- Headlight is a Vision-X Solstice 800 lumen LED spotlight

I took it to a small car show 2 months after I finished it and placed in the Top 10 out of 40 motorcycles.

Last edited: