The support tube was removed, but it was only for the front chain guard mount. The fender was not touched. Also removed the chain tensioner. I shortened the chain guard and made a small bracket to connect the front of the chain guard to the rear of the TC backplate.

Check back for pictures of the chain guard.

Check back for pictures of the chain guard.

Looks good; thanks for the pic. Apparently, at some time, the fender was longer and I had assumed it was attached to that tube; there were rear axle adjusters, too, as pictured on Walmart site. I hadn't looked at mine much; when it was delivered, I unboxed it and assembled it as quickly as I could, then put it in a shed; hadn't looked at it since. I just looked at it; mine has the short fender, too. I noticed the lack of axle adjusters when I put it together, but didn't notice the short fender. Guess they've been cutting costs.

Thanks for the info and pictures. I picked up one of the CT 100 via Amazon, because I couldn't find a used mini bike or a rolling chassis set up for anywhere near the price. I am pleasantly surprised overall. However, I am contemplating a CVT for the obvious reasons and they are available pretty cheap. I am thinking of relocating the fuel tank above the frame so I can raise the motor slightly more (1 1/2 inch square tube?) and not have to machine the CVT plate. I will post some pictures after I have the CVT in hand and start the install.

A tip/trick for those that install a TAV, be it on the CT100 or CT200. Toss the bolts that hold the cover on. Get longer bolts that have a shoulder on them. Cut off the head and excess thread. Drill a hole sideways through the shoulder on the new bolt so a hair pin clip can fit it.

Screw the new bolts in with Loctite, aligning the hair pin holes. Snap the cover over the new bolts and slap on the hair pins. Honestly if you make the new bolts long enough you could probably eliminate the hair pins.

Makes removal/install of the cover a snap instead of a pain getting all those bolts in.

Excuse the bolt photo, it's one I didn't use as the drill walked when drilling, but it gives you the idea of what I used.

And a shot of the cover on my CT200U

Screw the new bolts in with Loctite, aligning the hair pin holes. Snap the cover over the new bolts and slap on the hair pins. Honestly if you make the new bolts long enough you could probably eliminate the hair pins.

Makes removal/install of the cover a snap instead of a pain getting all those bolts in.

Excuse the bolt photo, it's one I didn't use as the drill walked when drilling, but it gives you the idea of what I used.

And a shot of the cover on my CT200U

Attachments

-

153.4 KB Views: 42

-

399.5 KB Views: 42

What size picture works best?

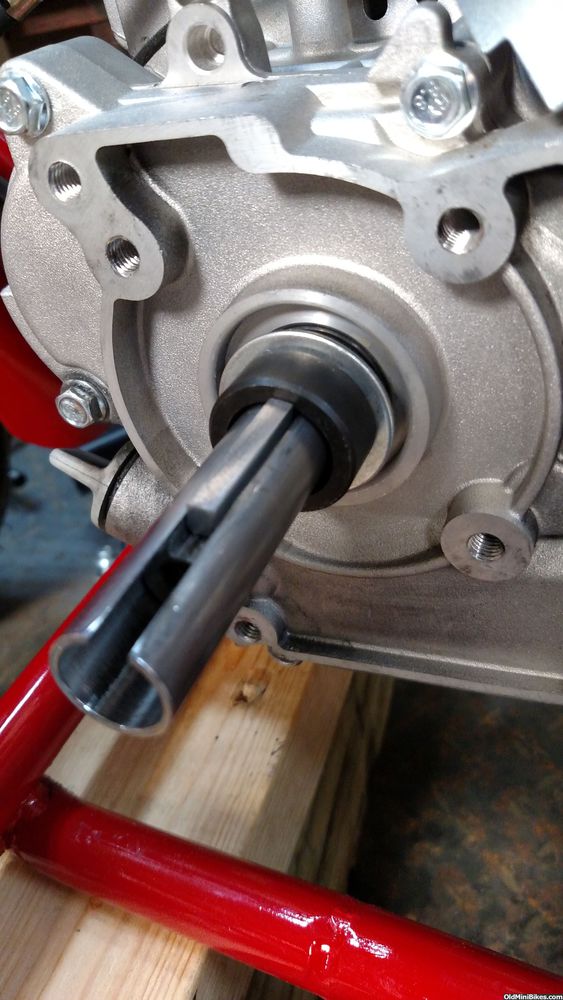

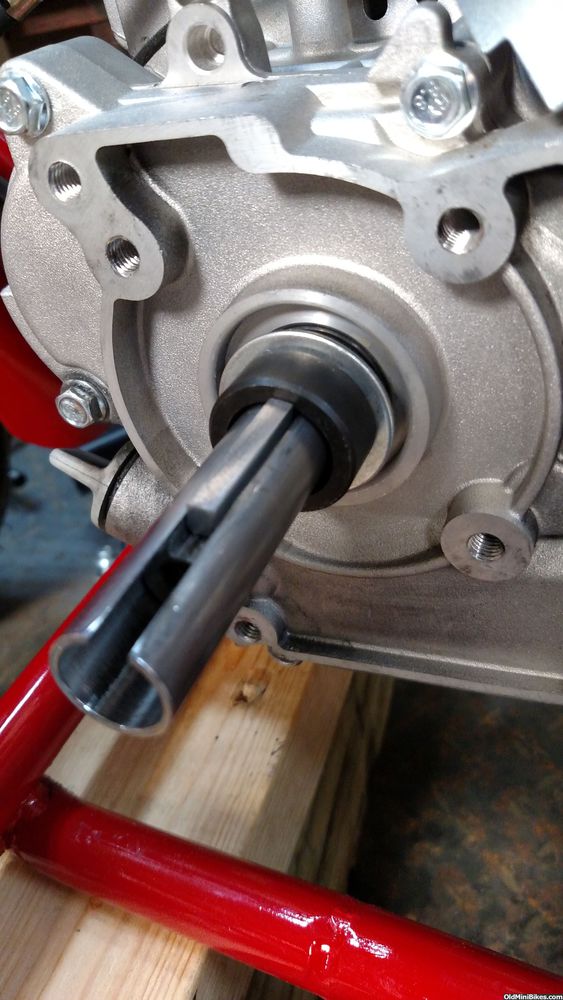

This is a 5/8 to 3/4 shaft adaptor. Had to ream inside with a 5/8 reamer using hose clamps to adjust size. Key that came with adaptor was 3/16 x 3/8. Milled it to 3/16 x 1/4.

Bored out formed key in back part of drive. Broached new 3/16 keyway.

Machined motor mount adaptors from aluminum. Mounts are 3/4 " height x 1.25 wide x 5" long, drilled and tapped to offset engine 1.25" to left.

Machined backplate to rotate on engine to workable position.

Spaced gas tank to right 1". Cut stock muffler off tubing and welded on 7/8" tubing bent almost 90 degrees. Tapped end of tubing 1/2" NPT for old style muffler. Stock muffler would not fit with engine raised 3/4".

This is a 5/8 to 3/4 shaft adaptor. Had to ream inside with a 5/8 reamer using hose clamps to adjust size. Key that came with adaptor was 3/16 x 3/8. Milled it to 3/16 x 1/4.

Bored out formed key in back part of drive. Broached new 3/16 keyway.

Machined motor mount adaptors from aluminum. Mounts are 3/4 " height x 1.25 wide x 5" long, drilled and tapped to offset engine 1.25" to left.

Machined backplate to rotate on engine to workable position.

Spaced gas tank to right 1". Cut stock muffler off tubing and welded on 7/8" tubing bent almost 90 degrees. Tapped end of tubing 1/2" NPT for old style muffler. Stock muffler would not fit with engine raised 3/4".