Alright, so I need some help and advice. Working on the 1970 Tecumseh H35 that came on my Rupp sprint. Replaced all the gaskets, cleaned it all up, for the life of me I couldn't get the diaphragm carb to work properly so for the time being I swapped on a float carb from a late 80s Tecumseh 3.5. The motor starts on either the first or second pull and idles great, but the instant I hit the throttle it sputters, won't rev, and ends up dying. Now if I let it come back to idle quick enough, it'll sputter back to life and idle fine. The carb ran perfect on the motor I pulled it from, what could be causing this and what do I need to look at/clean/adjust? I do not have a slant intake currently but I've been propping the bike up so the motor has been sitting level while I've been screwing with it so that's not the problem. Just need some help from the experts, thanks guys!

1970 Tecumseh H35, doesn't rev.

Like owend pointed out the bowl is not in the right position, now being in a slanted position thats probably not helping the already reduced operation of the float/needle. I would also pull the bowl and clean it out as well as the high speed. If you just bolted it on without taking it apart you may have just disturbed some light debris that was settled in the bottom of the bowl and it just went up into the jet.

Other noted thing is your plug wire....should come out the front the small cylinder shroud holds it in place away from the flywheel and the wire runs up the left side of the engine out of the way of exhaust, fuel line and linkages. Almost looks like there is a big melted spot on it from the exhaust, If theres a hole or thin enough area spark may be jumping too.

Other noted thing is your plug wire....should come out the front the small cylinder shroud holds it in place away from the flywheel and the wire runs up the left side of the engine out of the way of exhaust, fuel line and linkages. Almost looks like there is a big melted spot on it from the exhaust, If theres a hole or thin enough area spark may be jumping too.

Alright, I'm about to head out and mess with it some more. I do have the governor arm spring, I just hadn't hooked it up to the throttle yet. I'll try pulling the carb and doing a thorough cleaning and mess with the float bowl location. Like I said before when I'm messing with the motor I'm propping the front end of the bike so the motor is sitting level so for the time being I eliminate the angle factor. Havasu Dave, I don't have a timing light but is there anything I can visually look at to verify timing? Nothing looked altered/broken when I pulled the flywheel to get at the coil. I pulled the side cover to make sure crank/cam were lining up correctly. It's just weird, starts 1-2 pulls and sounds great at idle. Thanks for the help so far, hopefully I can get this thing going!

What do you mean you couldn't get the diaphragm carb to work properly? It wouldn't run? Or it had different set of problems? Or was it doing the same thing as it is with the bowl carb? You have to start at the basics and go from there. Like the question nobody asked...did it run before you touched it?

Nothing looked altered/broken when I pulled the flywheel to get at the coil.

Did you unbolt the coil, or loosen it? If so, I can almost guarantee it's out of time. I've never bought a used Tec that wasn't out of time.

But definitely ensure you have good fuel level in the float bowl first.

You don't time these with a timing light. It's a process involving an ohm meter and a depth gauge. The procedures are in the Tecumseh service manual which is on line in PDF format.

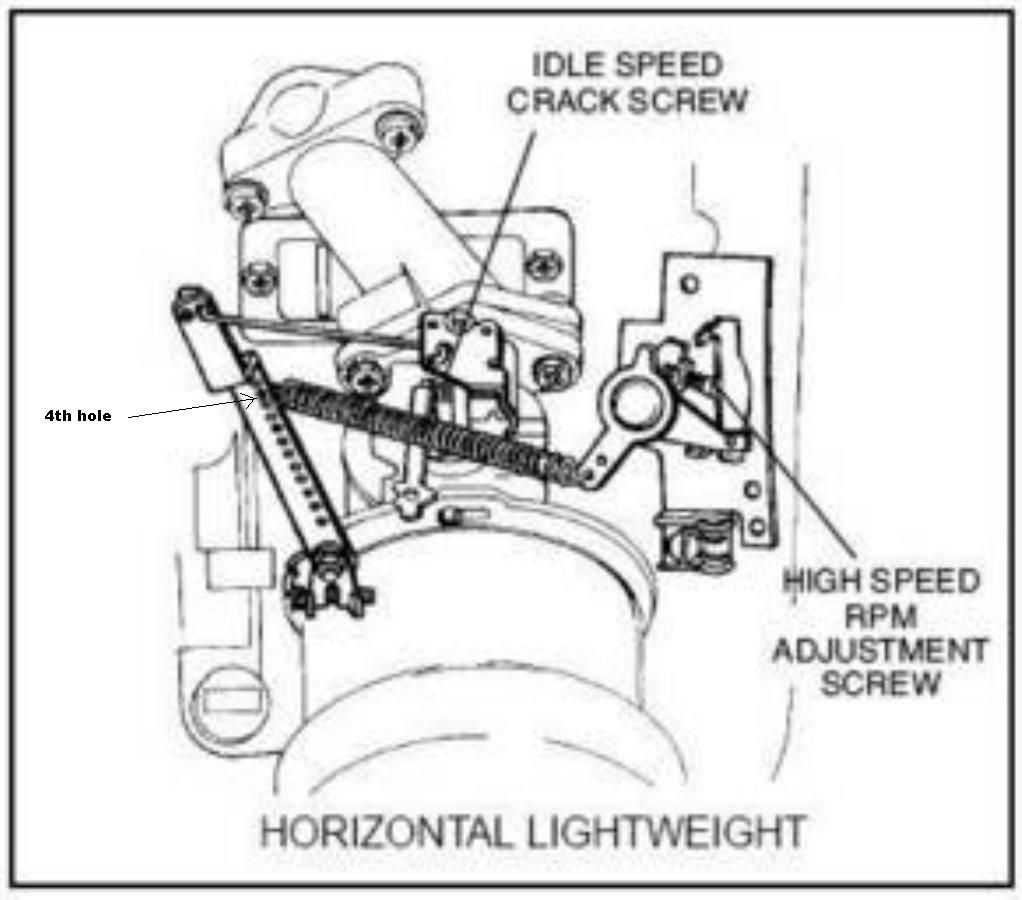

Carb- get it idling and increase idle set screw to raise RPM. Adjust low speed jet to get RPM to increase. Keep in mind you don't have a governor, and don't over-rev. Reduce idle set screw if RPM gets too high while adjusting the low speed jet. Once you have the maximum RPM you can get, do the same thing with the high speed jet on the bottom.

Now turn the idle set screw to normal idle RPM. The engine should accelerate when you move the throttle plate. You can't fine tune the high speed jet until you have it on a bike with a load on it and the governor hooked up and adjusted.

If the above carb adjustments don't fix the problem, you'll need to look into the timing. You need an ohm meter, (continuity tester) depth gauge, (dial indicator) feeler gauge, and have access to the proper procedures linked above.

Personally, when rebuilding an engine I just go ahead and buy a set of points and condenser. Cheap. But requires timing, since TDC points setting of .020" affects the timing at .065" BTDC timing setting.

And a bad condenser will cause it not to accelerate as well. Pay attention to that plug lead as Markus recommended.

Last bit of advice- don't time it at TDC and set coil gap (as seen on the internet) and assume all is good. It won't work. Don't attempt to install solid state timing in this motor. (also as seen on the internet) It won't work.

What do you mean you couldn't get the diaphragm carb to work properly? It wouldn't run? Or it had different set of problems? Or was it doing the same thing as it is with the bowl carb? You have to start at the basics and go from there. Like the question nobody asked...did it run before you touched it?

No, the motor did not run, who knows how long it had been sitting. It did have spark though. I bought a rebuild kit for the diaphragm carb, watched a few YouTube videos on how to rebuild it, and went at it. That thing was terrible, I spent the last week getting all the old tarred up fuel cleaned out. Now I did what the video recommended, wrote down the position of the adjustment screws the way the video described, but I doubt they were in proper position anyways. When I reinstalled the carb, couldn't get it to fire up, even with starting fluid. I wanted to see if if it would fire up with a different carb, threw on the float carb and it started 3rd pull. Now these issues. I need to do some more research on the diaphragm carb, the manual that Havasu Dave posted seems to have everything I need to know, but i at least want to get the motor running so that when I go back to the diaphragm I know that getting the carb dialed in is my only issue.

My two cent's worth:

Did you unbolt the coil, or loosen it? If so, I can almost guarantee it's out of time. I've never bought a used Tec that wasn't out of time.

But definitely ensure you have good fuel level in the float bowl first.

You don't time these with a timing light. It's a process involving an ohm meter and a depth gauge. The procedures are in the Tecumseh service manual which is on line in PDF format.

Carb- get it idling and increase idle set screw to raise RPM. Adjust low speed jet to get RPM to increase. Keep in mind you don't have a governor, and don't over-rev. Reduce idle set screw if RPM gets too high while adjusting the low speed jet. Once you have the maximum RPM you can get, do the same thing with the high speed jet on the bottom.

Now turn the idle set screw to normal idle RPM. The engine should accelerate when you move the throttle plate. You can't fine tune the high speed jet until you have it on a bike with a load on it and the governor hooked up and adjusted.

If the above carb adjustments don't fix the problem, you'll need to look into the timing. You need an ohm meter, (continuity tester) depth gauge, (dial indicator) feeler gauge, and have access to the proper procedures linked above.

Personally, when rebuilding an engine I just go ahead and buy a set of points and condenser. Cheap. But requires timing, since TDC points setting of .020" affects the timing at .065" BTDC timing setting.

And a bad condenser will cause it not to accelerate as well. Pay attention to that plug lead as Markus recommended.

Last bit of advice- don't time it at TDC and set coil gap (as seen on the internet) and assume all is good. It won't work. Don't attempt to install solid state timing in this motor. (also as seen on the internet) It won't work.

Did you unbolt the coil, or loosen it? If so, I can almost guarantee it's out of time. I've never bought a used Tec that wasn't out of time.

But definitely ensure you have good fuel level in the float bowl first.

You don't time these with a timing light. It's a process involving an ohm meter and a depth gauge. The procedures are in the Tecumseh service manual which is on line in PDF format.

Carb- get it idling and increase idle set screw to raise RPM. Adjust low speed jet to get RPM to increase. Keep in mind you don't have a governor, and don't over-rev. Reduce idle set screw if RPM gets too high while adjusting the low speed jet. Once you have the maximum RPM you can get, do the same thing with the high speed jet on the bottom.

Now turn the idle set screw to normal idle RPM. The engine should accelerate when you move the throttle plate. You can't fine tune the high speed jet until you have it on a bike with a load on it and the governor hooked up and adjusted.

If the above carb adjustments don't fix the problem, you'll need to look into the timing. You need an ohm meter, (continuity tester) depth gauge, (dial indicator) feeler gauge, and have access to the proper procedures linked above.

Personally, when rebuilding an engine I just go ahead and buy a set of points and condenser. Cheap. But requires timing, since TDC points setting of .020" affects the timing at .065" BTDC timing setting.

And a bad condenser will cause it not to accelerate as well. Pay attention to that plug lead as Markus recommended.

Last bit of advice- don't time it at TDC and set coil gap (as seen on the internet) and assume all is good. It won't work. Don't attempt to install solid state timing in this motor. (also as seen on the internet) It won't work.

Ok...then basically like Dave said in his last post. I would also put new points, condensor, plug and flywheel key and set the timing. I do that to all my Tecs and they run like a champ. Then you can go back and actually adjust your carb properly. And the diaphragm carb are very under rated. They are very simple and give comparable performance on stock motors. They just need to be cleaned very well.

Alright, well I'm done screwing with it for the day. No progress from yesterday, cleaned the hell out of the carb and tried the adjustments, no change, although I did get it idle really smooth :laugh:. Looks like I'll be ordering new points and condenser, also need to pick up the proper tools for setting the timing. It'll be a little bit until I'll be able to pick up everything I need, hopefully in a couple weeks. Thanks for all the advice so far guys and I'm sure I'll be asking more questions in a bit. Just trying to learn! Wish some of you guys lived closer, would love to learn first hand from you guys.