Who’s the powell experts….

- Thread starter Skipp

- Start date

Right now I know I need the swing arm spring….and one of those fancy knobs for the seat…one axle adjuster…I have a beat up one….I’m sure more to follow….

knowledge….

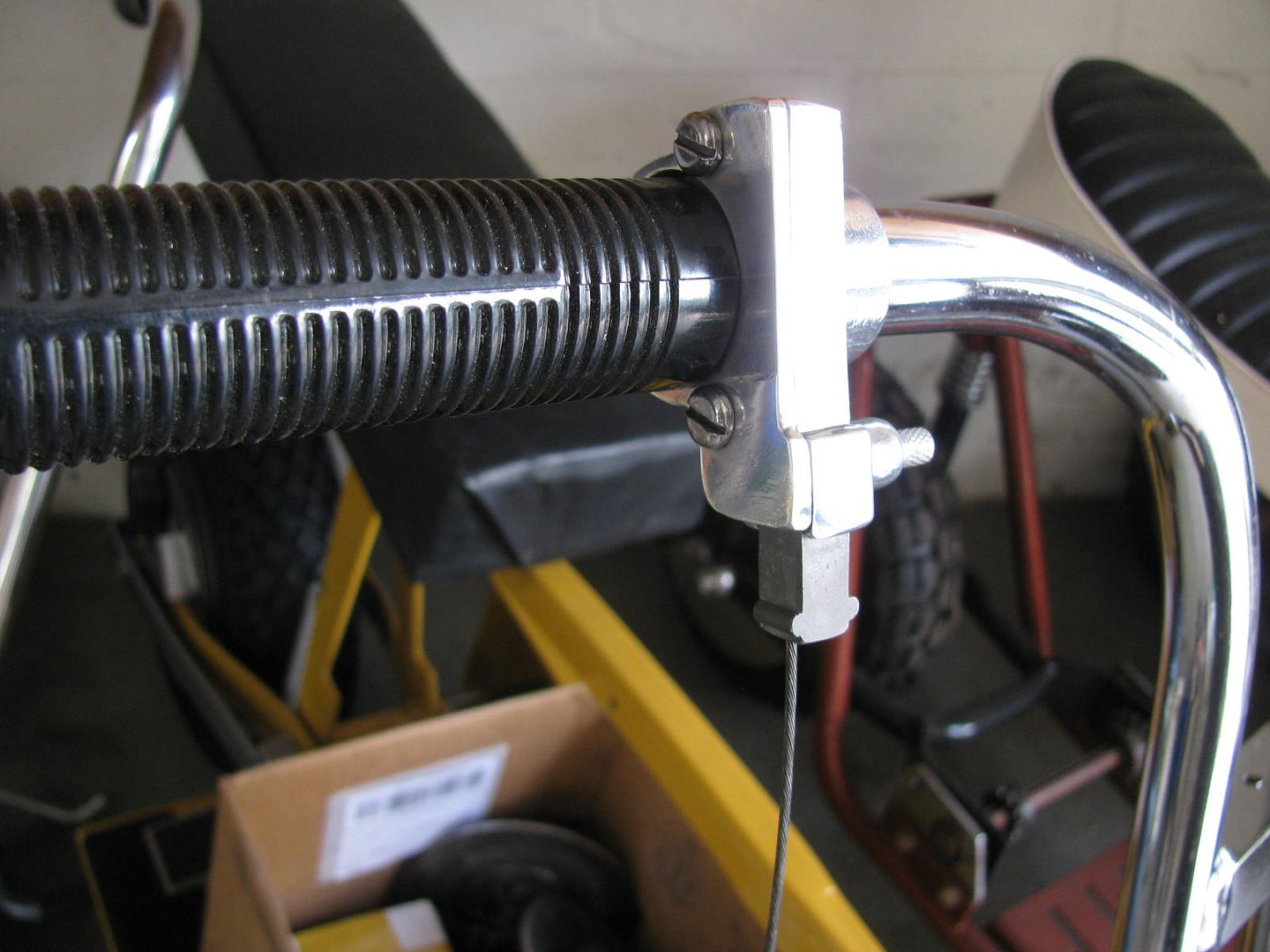

what’s the button knob thing on the bottom of the throttle!

It’s 1139 c

trying to figure how it all goes together….you know the fun part…

I’ve pulled up Havasu Dave’s build off thread someone named tippycanoes restore thread…but nothing specific I like details

and thanks for the replies

knowledge….

what’s the button knob thing on the bottom of the throttle!

It’s 1139 c

trying to figure how it all goes together….you know the fun part…

I’ve pulled up Havasu Dave’s build off thread someone named tippycanoes restore thread…but nothing specific I like details

and thanks for the replies

Last edited:

Nice, you got the throttle! Did you get the male cable part too? If not I think someone actually made their own on here one time and added it in a build thread......I just can't remember who that was though? I will say Be very careful with the assembly, One Dipshit I know dropped his during cleanup and busted the cover part when he had his

Thanks guys/gal

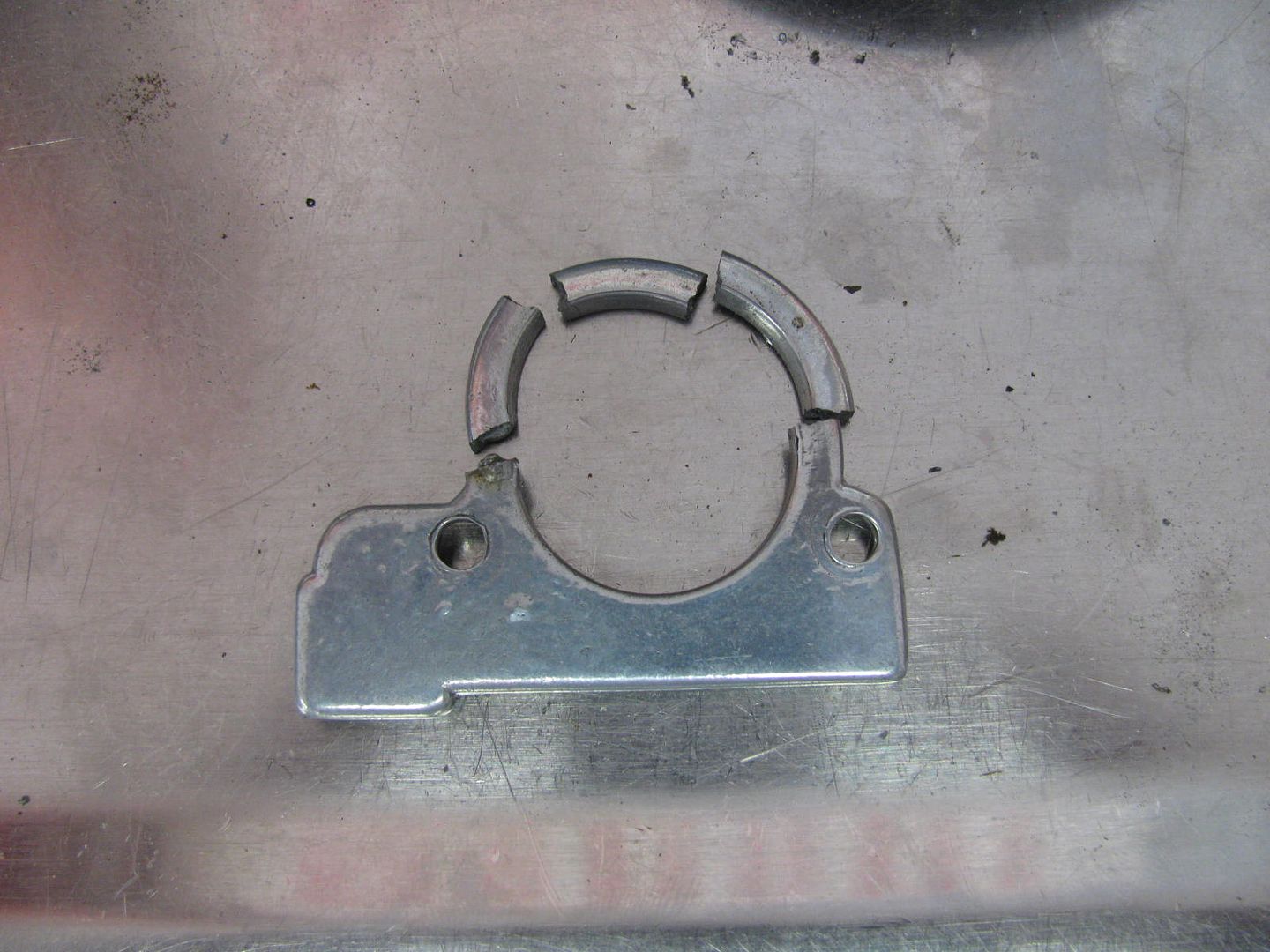

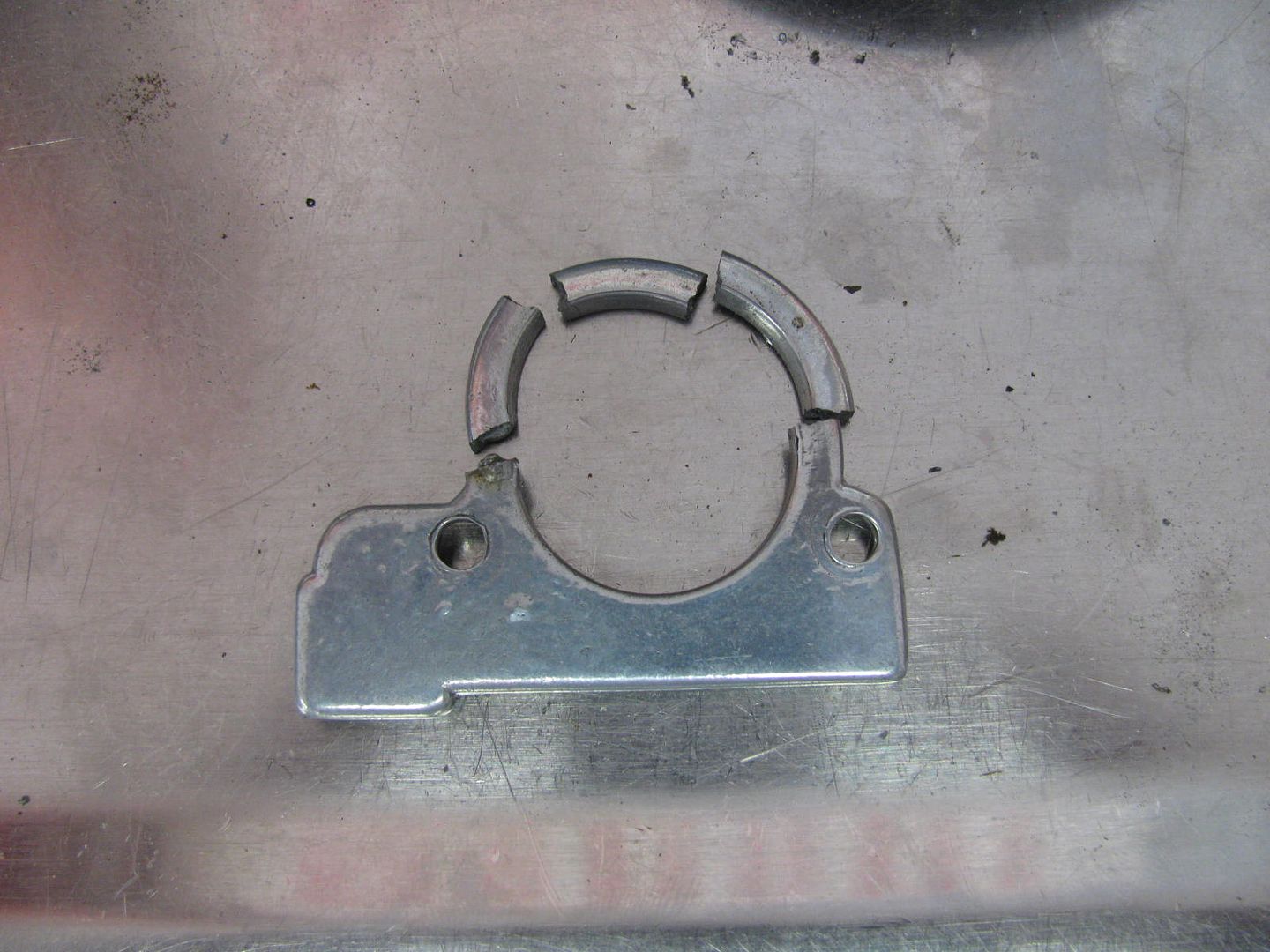

This weeks fiasco had do with me "butterfingers", and the throttle assy. What happens when you drop the plate that holds the throttle assy together......it shatters like glass :censure:

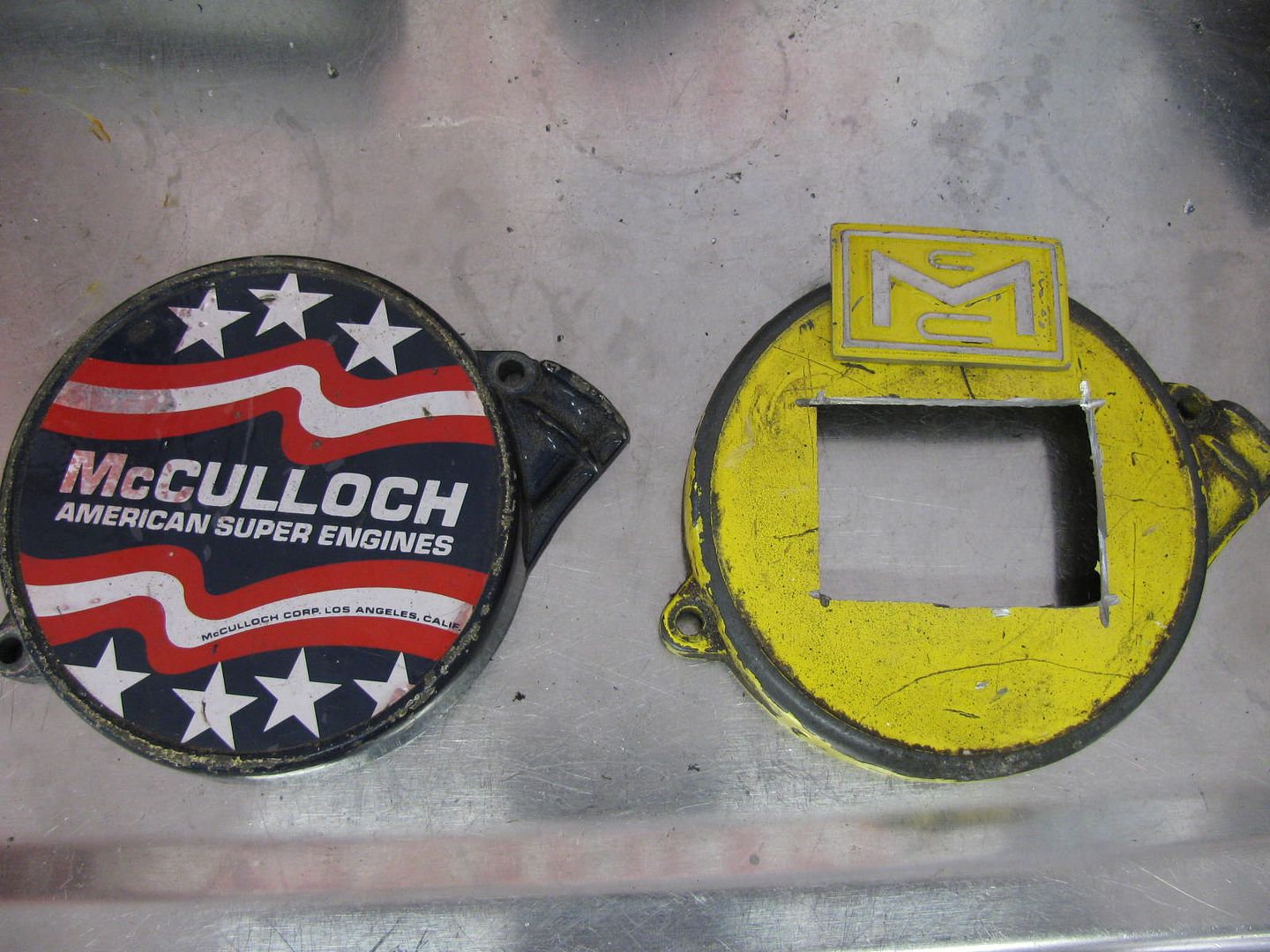

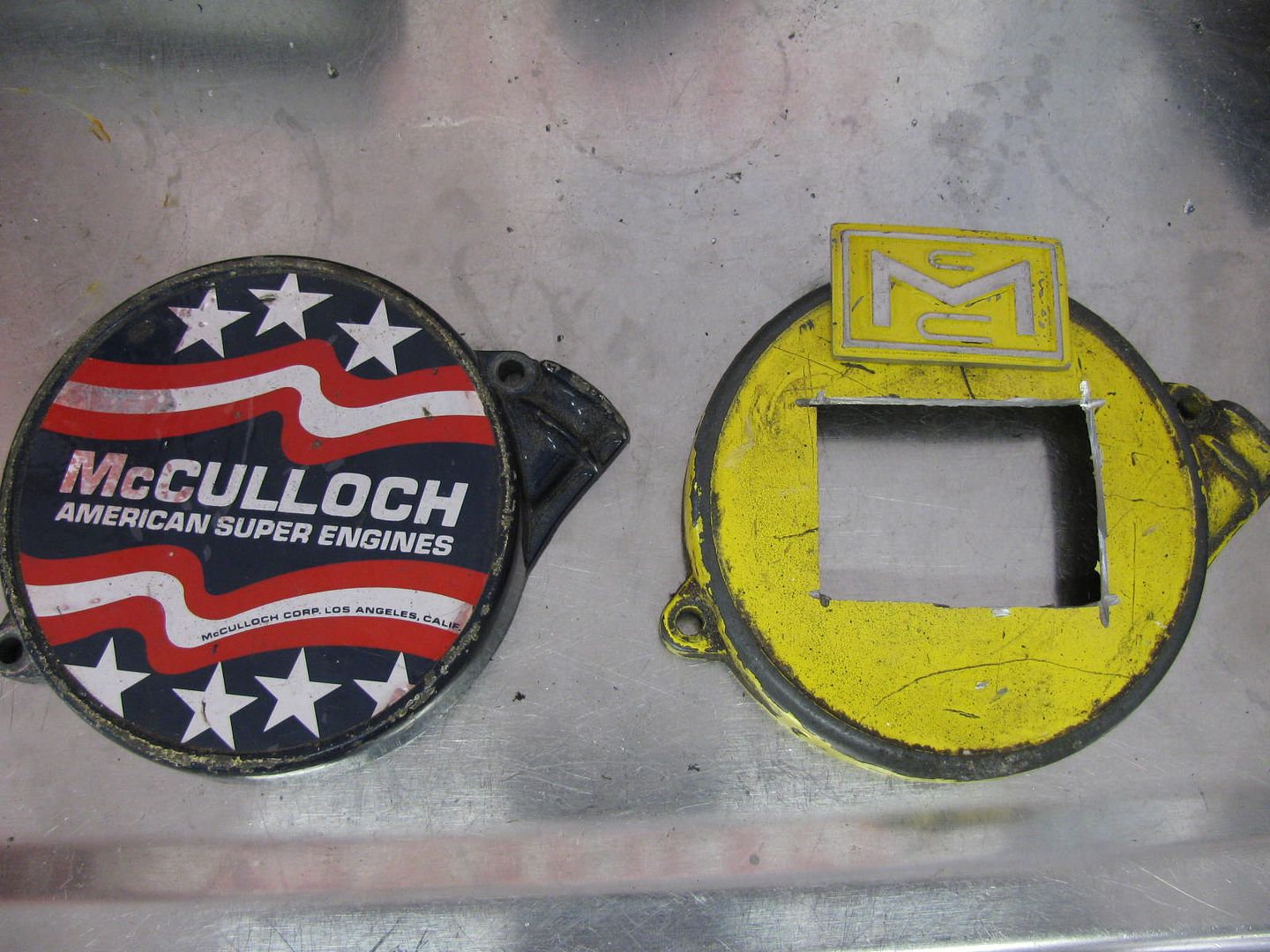

after some tears and whining I dried my eyes, picked up the pieces and tired to figure what the hell I was gonna do. I looked around for some scrap aluminum and didn't have anything in an appropriate size. I had checked both my well stocked local hardware store and even tractor supply when I was picking up some blasting media the other day neither had anything. I spotted some leftover cast pull start parts from a McCulloch I had. The yellow one had a curve to it but the later stickered one is very flat. I figured I'd test to see how it it cut on the yellow first so I cut out the insignia part and made myself a nice little badge out of it :thumbsup:

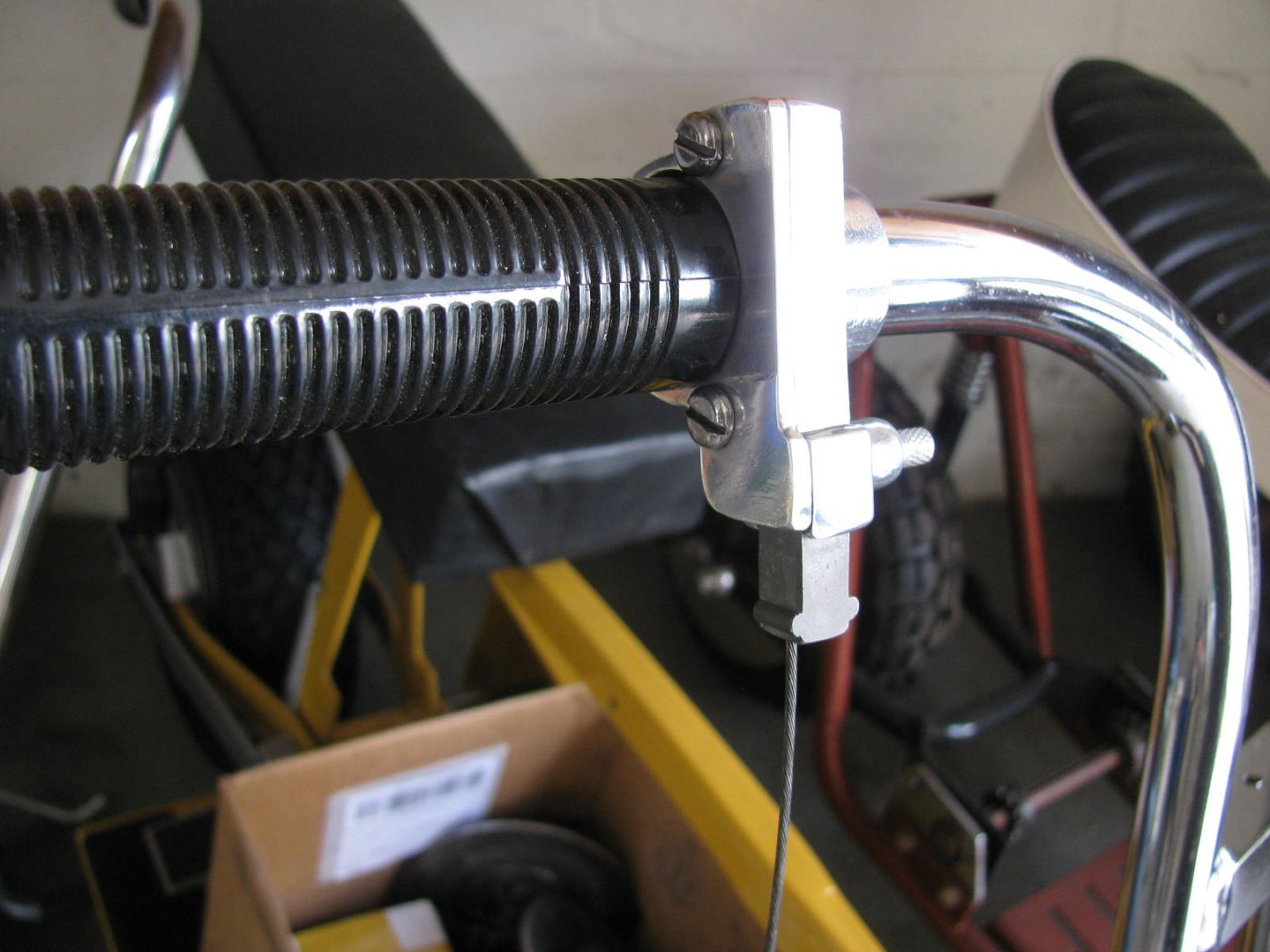

It cut fine with a cut off wheel so this morning I drilled the large hole first in the stickered one then traced out the remains of the original around it and rough cut it out, fitted it to the housing, and then smoothed it out to match the housing:

I shined it up a little, and tested it out. I can't get it to slip or fail, and its locking an quick releasing very well. but I am sure its a sloppier fit internally only because the original cast part had some slight built up sections inside. I am going to sort of copy them with a little JB weld...or at least try to help ensure there are no problems with it.

This weeks fiasco had do with me "butterfingers", and the throttle assy. What happens when you drop the plate that holds the throttle assy together......it shatters like glass :censure:

after some tears and whining I dried my eyes, picked up the pieces and tired to figure what the hell I was gonna do. I looked around for some scrap aluminum and didn't have anything in an appropriate size. I had checked both my well stocked local hardware store and even tractor supply when I was picking up some blasting media the other day neither had anything. I spotted some leftover cast pull start parts from a McCulloch I had. The yellow one had a curve to it but the later stickered one is very flat. I figured I'd test to see how it it cut on the yellow first so I cut out the insignia part and made myself a nice little badge out of it :thumbsup:

It cut fine with a cut off wheel so this morning I drilled the large hole first in the stickered one then traced out the remains of the original around it and rough cut it out, fitted it to the housing, and then smoothed it out to match the housing:

I shined it up a little, and tested it out. I can't get it to slip or fail, and its locking an quick releasing very well. but I am sure its a sloppier fit internally only because the original cast part had some slight built up sections inside. I am going to sort of copy them with a little JB weld...or at least try to help ensure there are no problems with it.

Nice, you got the throttle! Did you get the male cable part too? If not I think someone actually made their own on here one time and added it in a build thread......I just can't remember who that was though? I will say Be very careful with the assembly, One Dipshit I know dropped his during cleanup and busted the cover part when he had his

View attachment 302565

View attachment 302565

I made my own male piece, but I certainly would not want to take a trip deep in the woods as It would probably lose its teeth. OK so 1st picture is the real powell cable end. Second pic is the spring from century that I used along with the original inner spring and it works just fine. The rest of the pictures are of me making the cable end parts from some solid aluminum b

Attachments

-

768.4 KB Views: 27

-

4.2 MB Views: 24

-

4.1 MB Views: 23

-

4.3 MB Views: 22

-

3.6 MB Views: 23

-

3.5 MB Views: 22

-

3 MB Views: 23

-

3.6 MB Views: 19

-

3 MB Views: 21

Here is the spring and part # from century. I had to buy 3 but I sold one to Angelo and he said it was too soft, I did not find mine to be soft at all but they came with a inner and outer spring. My original outer was bad but the inner was ok and I have that inside the big spring. Last pic has the inner spring.

Attachments

-

4.2 MB Views: 16

-

4.1 MB Views: 17

-

4.2 MB Views: 17

I made one that was a copy of my old one. Not sure that the old one was original or not. Right now I have the idler pully in the middle of the belt and when the lever is allowed to go forward it pulls down the bottom of the belt. Someone on here or another forum said the pulley should be over the top of the belt but I don't think I can do that without a longer belt. Here are pics of what I made and the original had the pulley axle welded to the arms, on mine I used a bolt and it does hit the frame and limit travel. I originally had a allen bolt with a nylok but had to remove it and use a much narrower bolt and thinned nut to avoid the frame. You can see the added 1/8 spacer I added to the pulley as I used a comet driver on the engine that uses a 3/4 belt. The original powell used a 5/8 belt.

Attachments

-

4.3 MB Views: 17

-

4.2 MB Views: 17

-

4 MB Views: 17

-

4.2 MB Views: 14

-

4.2 MB Views: 15

-

4.3 MB Views: 13

-

4.2 MB Views: 13

-

4.3 MB Views: 13

-

4.2 MB Views: 11

-

4.3 MB Views: 16

-

4.3 MB Views: 17