Hello,

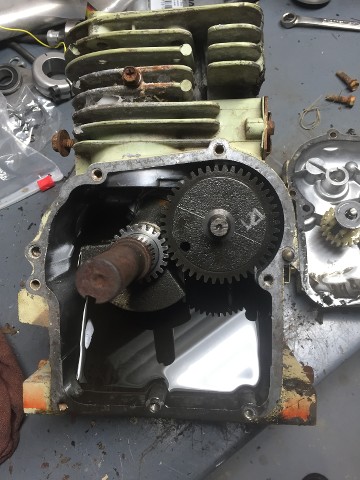

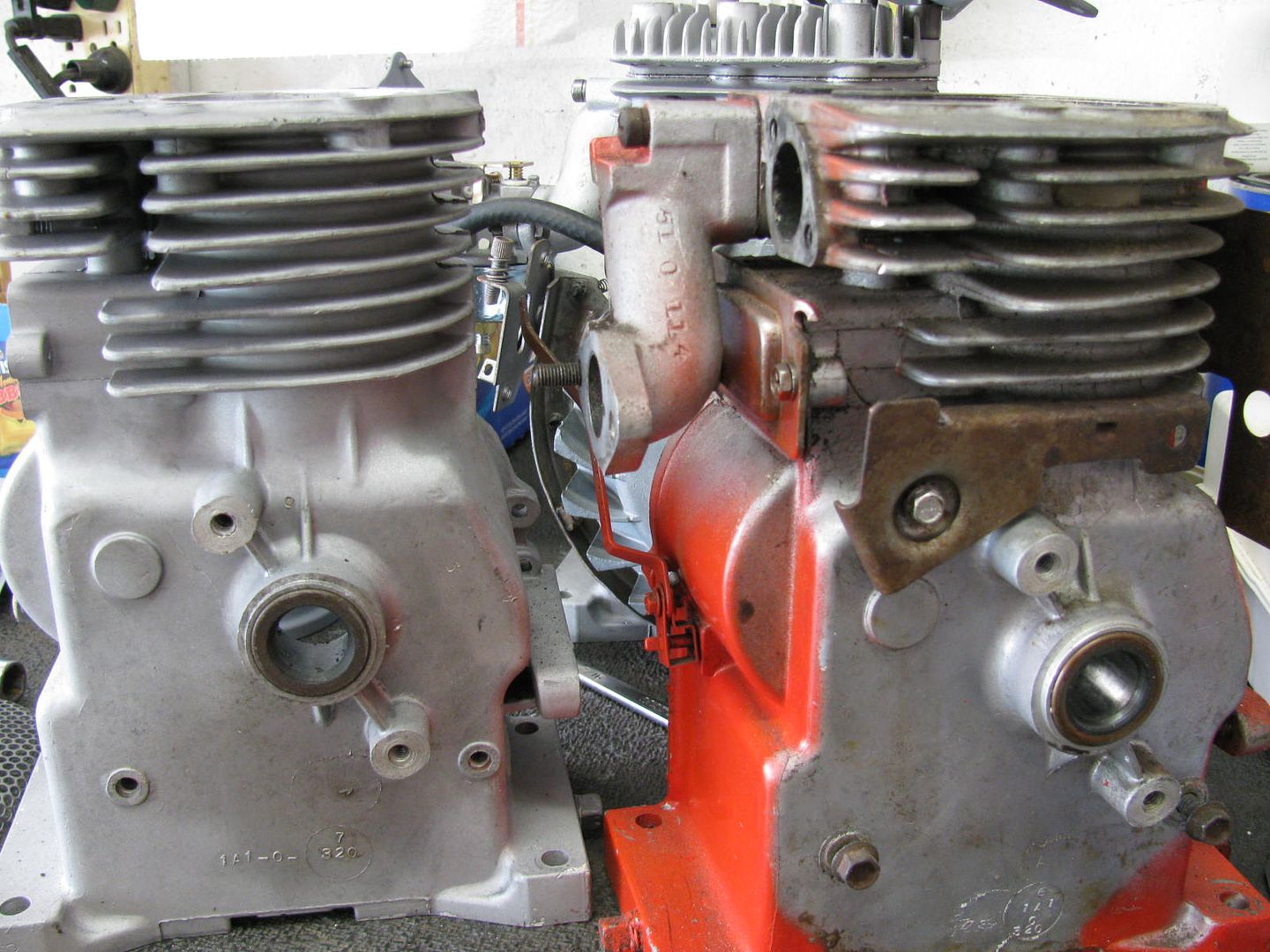

I am kind of a new with these HS50 engines, I still can't believe it's a 5hp from the size of the engine and the weight lol.

Motor has compression and spark, other than that I know nothing about it, I just bought it today.

My questions are:

Are there any performance parts like billet rods/flywheels readily available for these HS50s? I was thinking of taking the governor out and installing billet rod/piston/flywheel. Will the cast crank take much abuse? Are there aftermarket cranks available for these?

I noticed the intake manifold looks like a periscope, can I just build my own straight intake and then put like an 18mm Mikuni on it with a remote tank?

Is there a HP/TQ threshold with these blocks? They are awfully small and light for their size and I'm guessing it's because the castings are thin. Any confirmation on this? Is there a thread that explains this? I am searching now but mostly getting "H50 vs HS50" type threads, haven't found one yet that lists any performance parts or even factory parts upgrades if there are any.

I'll keep looking in the meantime, thanks in advance for any help! Any advice, just let it fly

I am kind of a new with these HS50 engines, I still can't believe it's a 5hp from the size of the engine and the weight lol.

Motor has compression and spark, other than that I know nothing about it, I just bought it today.

My questions are:

Are there any performance parts like billet rods/flywheels readily available for these HS50s? I was thinking of taking the governor out and installing billet rod/piston/flywheel. Will the cast crank take much abuse? Are there aftermarket cranks available for these?

I noticed the intake manifold looks like a periscope, can I just build my own straight intake and then put like an 18mm Mikuni on it with a remote tank?

Is there a HP/TQ threshold with these blocks? They are awfully small and light for their size and I'm guessing it's because the castings are thin. Any confirmation on this? Is there a thread that explains this? I am searching now but mostly getting "H50 vs HS50" type threads, haven't found one yet that lists any performance parts or even factory parts upgrades if there are any.

I'll keep looking in the meantime, thanks in advance for any help! Any advice, just let it fly