I'm new here and have been reading about fitting torque converters to Coleman 200 minibikes. Has anyone done this to a CT100? I assume it has the 5/8 engine shaft. Haven't seen the bike yet. Due for delivery today. Great site by the way. It's good to see a site without so much drama as some of the others have. Everyone for the most part seems to respect each other here.

Thanks. UPS delivered the bike this afternoon. My grandson and I bolted on the forks, fender, wheel, chain guard, we added oil and gas, oiled the clutch bushing, and fired it up. We all had a blast with it, especially my grandson. Quality looks pretty good for Chinese. Still want to put a torque converter on it.

Wheelbase is 34". It's small, perfect size for my grandson. It does not have the jackshaft arrangement that I see on the 200, just clutch sprocket to rear wheel sprocket, with a tensioner. Book says 6.3:1 gear ratio with AT145/70-6 tires. Rear sprocket is huge. Maybe I should scrounge up for a 200 for myself!

What size picture works best?

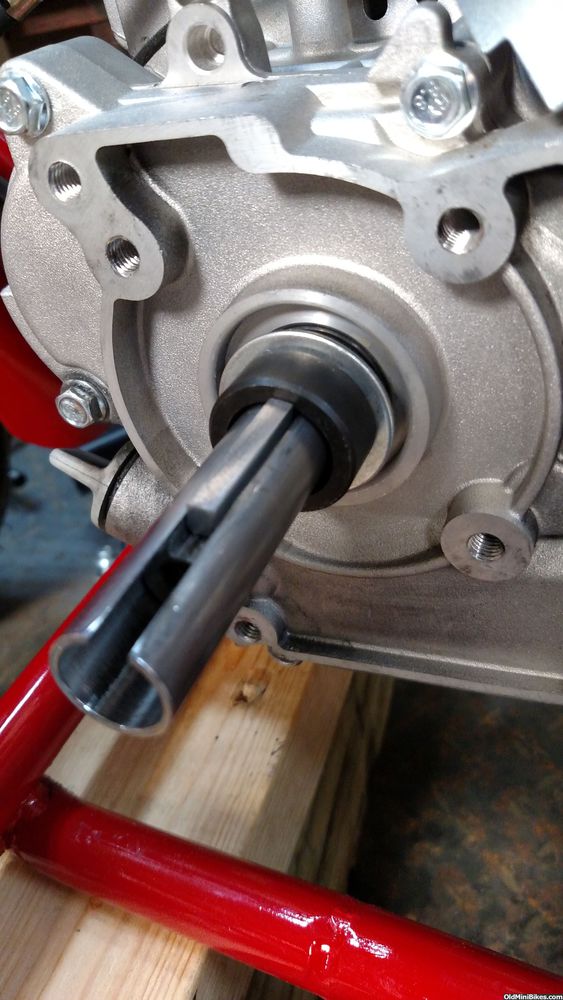

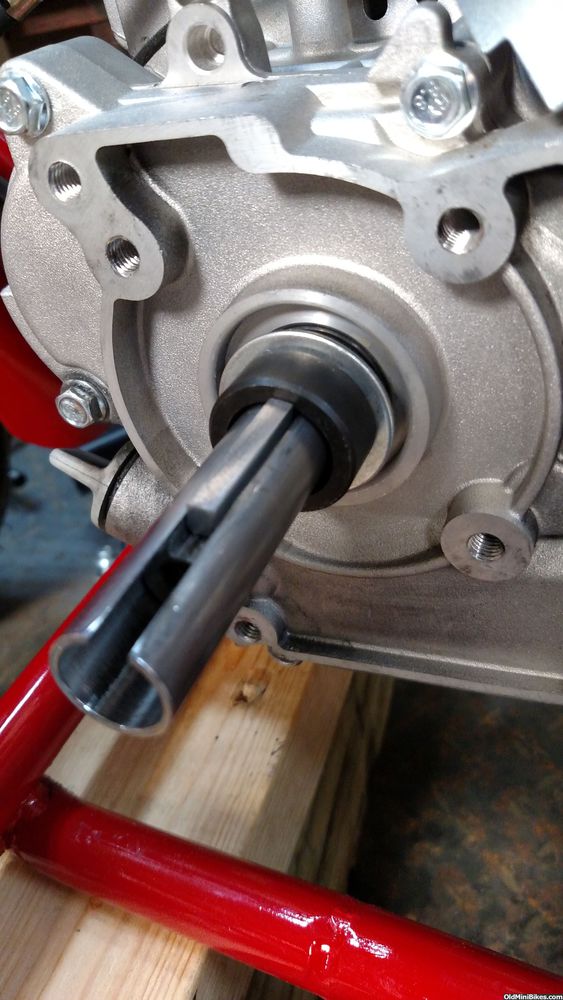

This is a 5/8 to 3/4 shaft adaptor. Had to ream inside with a 5/8 reamer using hose clamps to adjust size. Key that came with adaptor was 3/16 x 3/8. Milled it to 3/16 x 1/4.

Bored out formed key in back part of drive. Broached new 3/16 keyway.

Machined motor mount adaptors from aluminum. Mounts are 3/4 " height x 1.25 wide x 5" long, drilled and tapped to offset engine 1.25" to left.

Machined backplate to rotate on engine to workable position.

Spaced gas tank to right 1". Cut stock muffler off tubing and welded on 7/8" tubing bent almost 90 degrees. Tapped end of tubing 1/2" NPT for old style muffler. Stock muffler would not fit with engine raised 3/4".

This is a 5/8 to 3/4 shaft adaptor. Had to ream inside with a 5/8 reamer using hose clamps to adjust size. Key that came with adaptor was 3/16 x 3/8. Milled it to 3/16 x 1/4.

Bored out formed key in back part of drive. Broached new 3/16 keyway.

Machined motor mount adaptors from aluminum. Mounts are 3/4 " height x 1.25 wide x 5" long, drilled and tapped to offset engine 1.25" to left.

Machined backplate to rotate on engine to workable position.

Spaced gas tank to right 1". Cut stock muffler off tubing and welded on 7/8" tubing bent almost 90 degrees. Tapped end of tubing 1/2" NPT for old style muffler. Stock muffler would not fit with engine raised 3/4".

Engine is original 3 HP. Modified the throttle linkage to match twist grip travel to engine throttle travel. The 6" driven with overdrive prevents engine from revving much over stock. This torque converter is such an improvement over a clutch!! It wants to pop wheelies unless I sit forward on seat. I set throttle stop about 8 turns in when my grandson rides. Very smooth throttle.