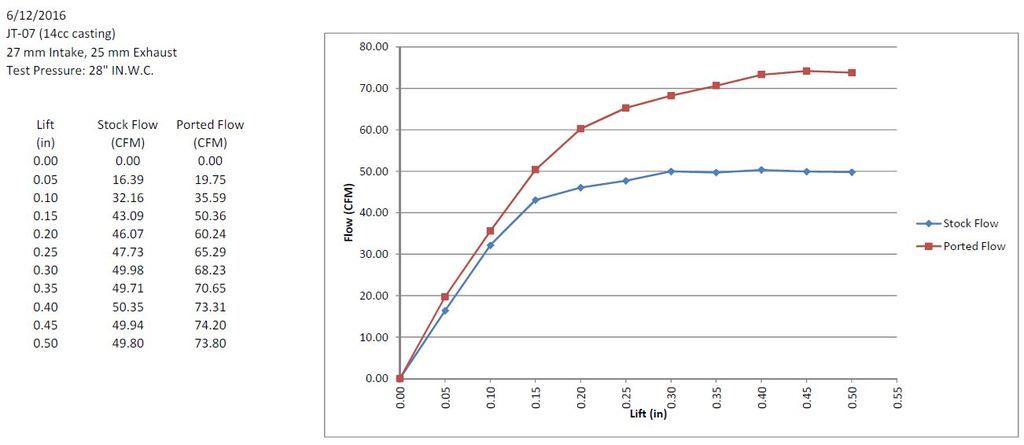

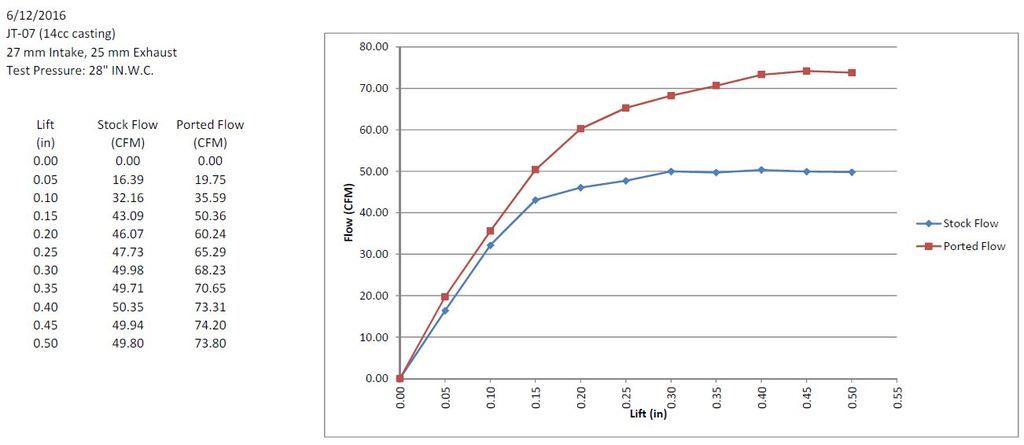

What kind of flow numbers are others seeing on their heads? I've been playing with 27mm intake valves recently and the last couple heads I've been topping out in the mid 70's for the CFM. Here's the flow data for the last head I did. Anybody have any tips to share or have I pretty much reached the potential for a 27mm intake valve and it's time to step up to a larger valve.