I've never welded with a torch, is it hard to do compared to stick welding? I can stick weld, but tried a wire feed one time, and could not get it going. I probably just needed to practice some more.

I know, I have heard stories about people who like them, and people who hate them. I probably won't get one at all from HF. Just venting my frustration with all the stuff I want and need to weld, and no welder. I'm thinking I can find a good stick welder on craigslist. That's the only kind of welding I can do, but who knows. Thanks for your review of the welder. Did you buy a different one?

I know, I have heard stories about people who like them, and people who hate them. I probably won't get one at all from HF. Just venting my frustration with all the stuff I want and need to weld, and no welder. I'm thinking I can find a good stick welder on craigslist. That's the only kind of welding I can do, but who knows. Thanks for your review of the welder. Did you buy a different one?

Until I decide on something I'm going to want to stick with and afford, I use a Hobart at a friends house when I need to weld anything.

I've never welded with a torch, is it hard to do compared to stick welding? I can stick weld, but tried a wire feed one time, and could not get it going. I probably just needed to practice some more.

Interesting post as to quenching, and HF welders.

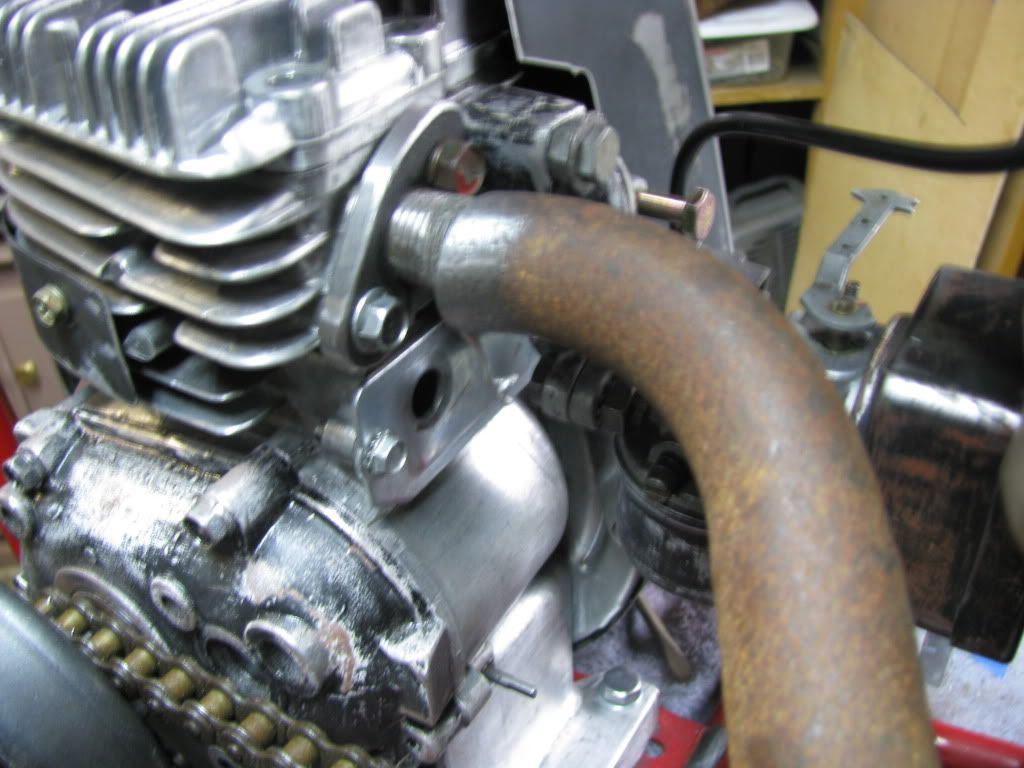

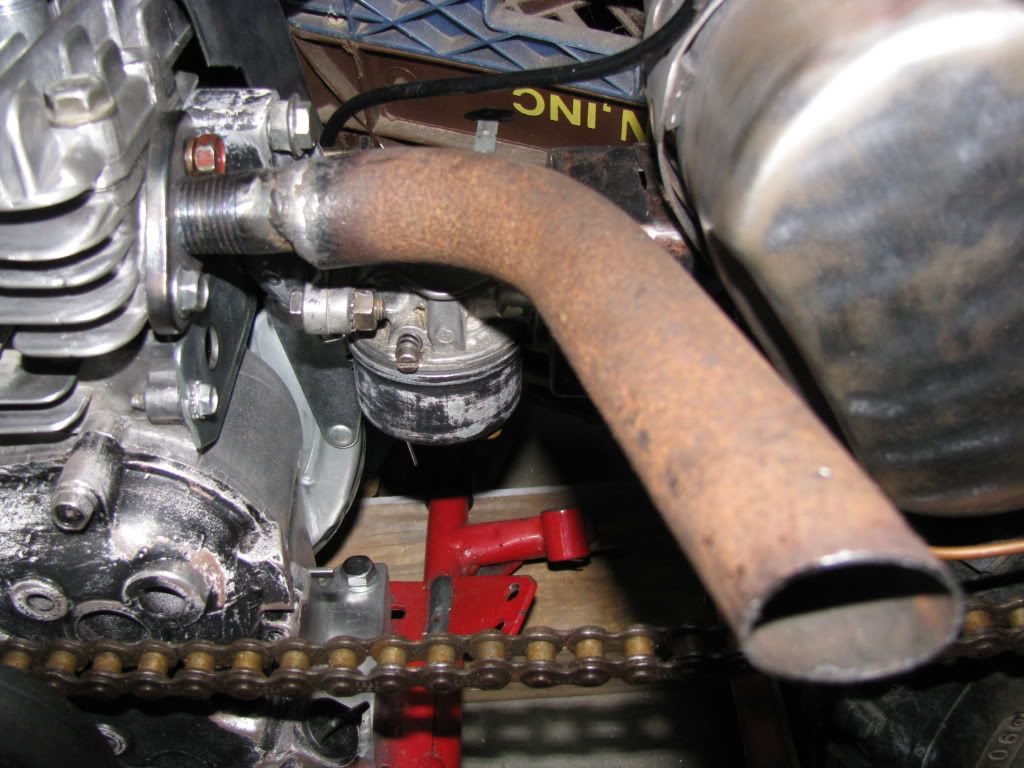

This is a mount for a header so no need to heat treat mild steel as that is what you are probably using.

A 90A wire welder is good for sheet metal to about 14 guage.

Go up to a 120-130A (prefer 130A) for anything in the real world as you can usuallpy adjust it for anywhere from the 90 to the 13A level. Hate to say it but most of the major USA mfg import from China now.. so what you see at HF is in a different package from your favorite US mfg.

Toss any welding rod or spools from HF or any other discounter including Walmart, HD, Lowes and Sears. They are crap and who knows how long they sat in the salty air comming over from ???

Go to a real welding supply store and admit you do not know a thing about welding (Play the dummy) but show them what you want to do. They are more then happy to sell you the correct wire and tell you how to use and store it (dry, dry, dry place)

If you have a wire feed, stick welder or gas you keep your rods, wire in a air tight container and buy quality rods to start with, diff rods for diff projects and that is not just the material but the size of the rod and coating. Tips are replaceable and wear out and need cleaned so get used to maintance of the equipment.

Wire feed is the easiest to use, stick earns its keep for heavy industrial use and if your into repairing machinery and a lot of cast iron the only way to go, gas is very easy to learn and difficult to master but worth the time to learn, If you ever soldered a water pipe you can gas weld (ok, somewhat).

I built a Whitman Tailwind (homebuilt aircraft) over 30 years ago and it was all gas welding as NO other welding was allowed on a homebuilt aircraft back then, the welding was the most difficult I ever did but now I can weld just about anything anywhere in any position with gas (yes you will learn about heatsinks and heat treatment in the process).

For most of the welding we would be doing on a bike go with a 130A MIG/TIG and quality wire and practice, besides with the right wire and a gas tank you can weld aluminum with the same outfit, much more easily and at a lower cost then with stick or gas.

This is a mount for a header so no need to heat treat mild steel as that is what you are probably using.

A 90A wire welder is good for sheet metal to about 14 guage.

Go up to a 120-130A (prefer 130A) for anything in the real world as you can usuallpy adjust it for anywhere from the 90 to the 13A level. Hate to say it but most of the major USA mfg import from China now.. so what you see at HF is in a different package from your favorite US mfg.

Toss any welding rod or spools from HF or any other discounter including Walmart, HD, Lowes and Sears. They are crap and who knows how long they sat in the salty air comming over from ???

Go to a real welding supply store and admit you do not know a thing about welding (Play the dummy) but show them what you want to do. They are more then happy to sell you the correct wire and tell you how to use and store it (dry, dry, dry place)

If you have a wire feed, stick welder or gas you keep your rods, wire in a air tight container and buy quality rods to start with, diff rods for diff projects and that is not just the material but the size of the rod and coating. Tips are replaceable and wear out and need cleaned so get used to maintance of the equipment.

Wire feed is the easiest to use, stick earns its keep for heavy industrial use and if your into repairing machinery and a lot of cast iron the only way to go, gas is very easy to learn and difficult to master but worth the time to learn, If you ever soldered a water pipe you can gas weld (ok, somewhat).

I built a Whitman Tailwind (homebuilt aircraft) over 30 years ago and it was all gas welding as NO other welding was allowed on a homebuilt aircraft back then, the welding was the most difficult I ever did but now I can weld just about anything anywhere in any position with gas (yes you will learn about heatsinks and heat treatment in the process).

For most of the welding we would be doing on a bike go with a 130A MIG/TIG and quality wire and practice, besides with the right wire and a gas tank you can weld aluminum with the same outfit, much more easily and at a lower cost then with stick or gas.

Last edited:

I too have a HF mig welder (131a) older one I bought off Ebay about 4 years ago and have put 6lbs of wire through it(flux) with no weld failures yet on any of the items I've built or repaired. I use the Lincoln wire sold at Lowes. If you are not building a rocket ship they (HF welders) and some skill will do. Good Luck

Thanks Bill and Bugger. I am still deciding on what I want, vs. what I might be able to afford. I agree that going to a welding supply house is a good idea, and we have one here in town. I always do a lot of research and get opinions from others before I buy a big ticket item. I consider any welder a big ticket item. I appreciate the time you both took to give your advice. Thanks. I'll be sure to post a picture of what I get and report on how it works. I am pretty good at stick welding, but that is all I can really do. I have not tried all the new fancy welders yet.