I haven't posted any form of project or a how to thread in some time so I decided to make a thread on a new part I will be making soon.

I will go through all the steps in real time so it might get a little boring over the next couple weeks but it is what I have to go through in making a part.

No, there will be no royalties because you read this thread...

First thing is deciding on what parts to make and if it is worth while, on this part I need a few and so does a unnamed friend who will be helping with this project, and I know it is probably good for a solid 20 parts sold quick then one here and there.

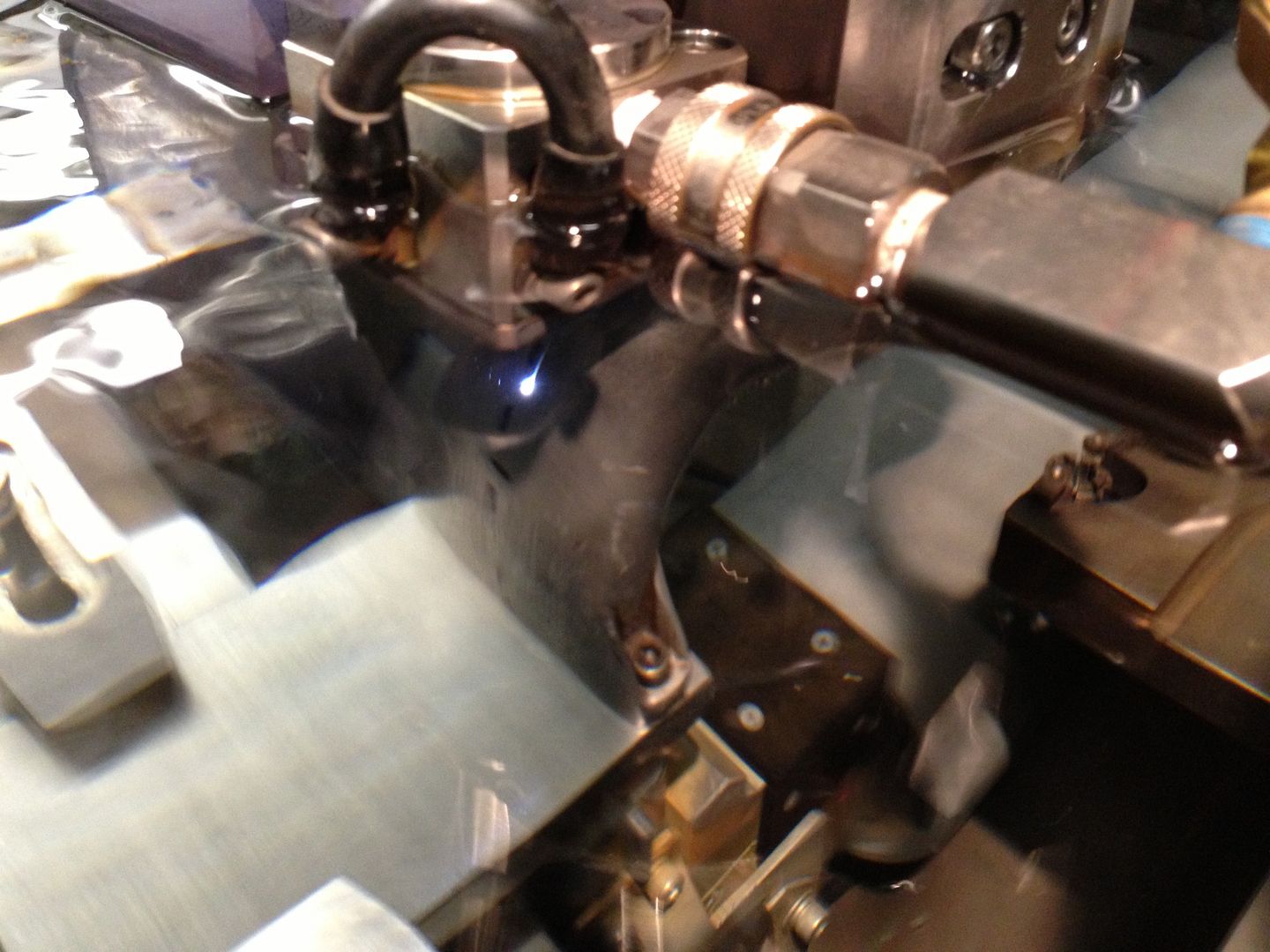

My new part will be a McCulloch Header they are cool looking rare and well just cool looking...

This was my first step playing the auction game to get a doner part

Vintage Kart McCulloch Bugle Exhaust Racing Go Cart | eBay

I will go through all the steps in real time so it might get a little boring over the next couple weeks but it is what I have to go through in making a part.

No, there will be no royalties because you read this thread...

First thing is deciding on what parts to make and if it is worth while, on this part I need a few and so does a unnamed friend who will be helping with this project, and I know it is probably good for a solid 20 parts sold quick then one here and there.

My new part will be a McCulloch Header they are cool looking rare and well just cool looking...

This was my first step playing the auction game to get a doner part

Vintage Kart McCulloch Bugle Exhaust Racing Go Cart | eBay