Got my new rear axle shaft in from OldMiniBikes. Still no stickers...:no:

I had to grind out the slots a little bit in the harder compound brake pads. The slots were too narrow for the V-shaped metal return spring for the pads.

Sorry about too much flash. You can just barely see the V-shaped return spring below the pads.

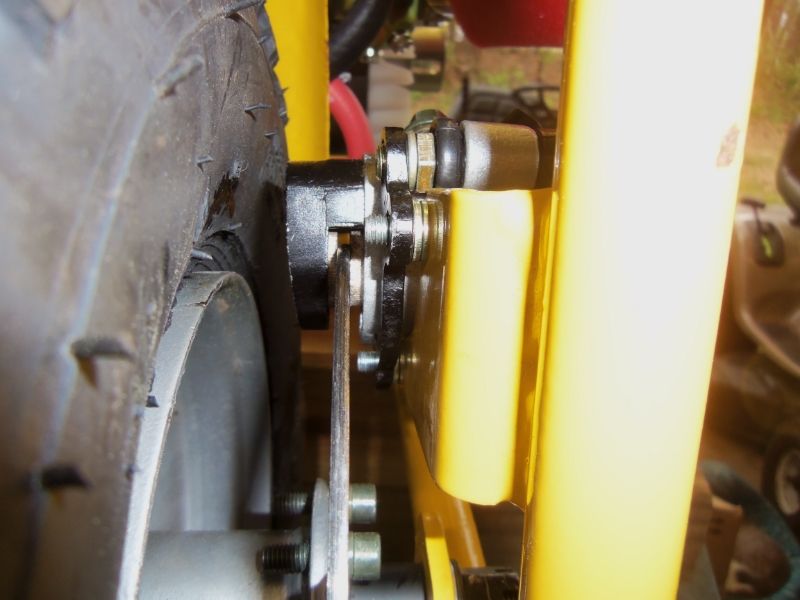

Hydraulic brake caliper bolted up with no problems.

I ended up using two washers between the caliper bracket and the mounting tab to center the caliper over the brake rotor. As such, I had to use longer mounting bolts.

Alright, at this point, I test fired the engine. It started on the first pull, but was a little raggedy. it surged some and had the occasional backfire. I tweaked the idle mixture screw to get the smoothest idle once it warmed up. Idle ended up being 1200 RPM. Idle has a lope to it and burbles out of the open header.

Warmed up, the engine would run up to 3900 WOT. Over the next two days I put 30 minutes on the engine, varying the RPM and such. Other than some low speed vibrations, I had no issues from the engine.

The TAV however, was another story. It was neat watching the pulleys shift and the belt move. Then the belt started smoking at higher RPM's. I thought the plate was cocked at its back end. More testing pretty much shredded the beveled edge of the belt. I also figured out what was wrong.

Remember me talking about getting medieval with the grinding of the TAV plate to make it tuck up next to the engine? I went too far.

The back end of the TAV plate, that carries the secondary pulley, flexed out under load, allowing the belt to bias into the driven pulley, shredding it. There was no fix. You can't effectively put metal back after you grind it off.

So, I had to buy another TAV2 kit. That was a nice $200 mistake. :censure:

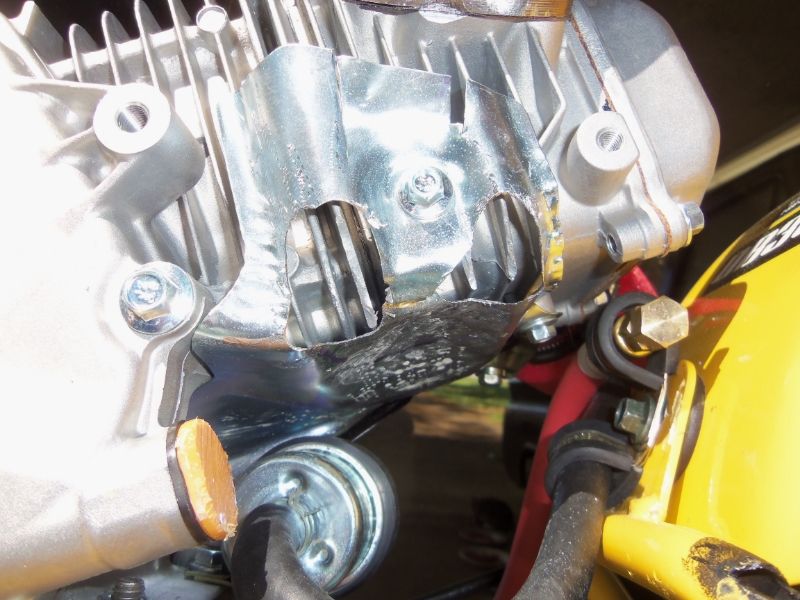

This time, I ground the slot at the back tighter, and did very, very little grinding to the TAV plate itself. Instead, I got medieval on the cylinder air baffle...

I ground these two holes in the baffle for clearance of two gussets on the bearing snout on the back of the TAV plate. I ground a slight amount off a few cylinder fins, and dimpled the baffle a little more. Now, the TAV fits in the same place as the other one, but is not weakened.

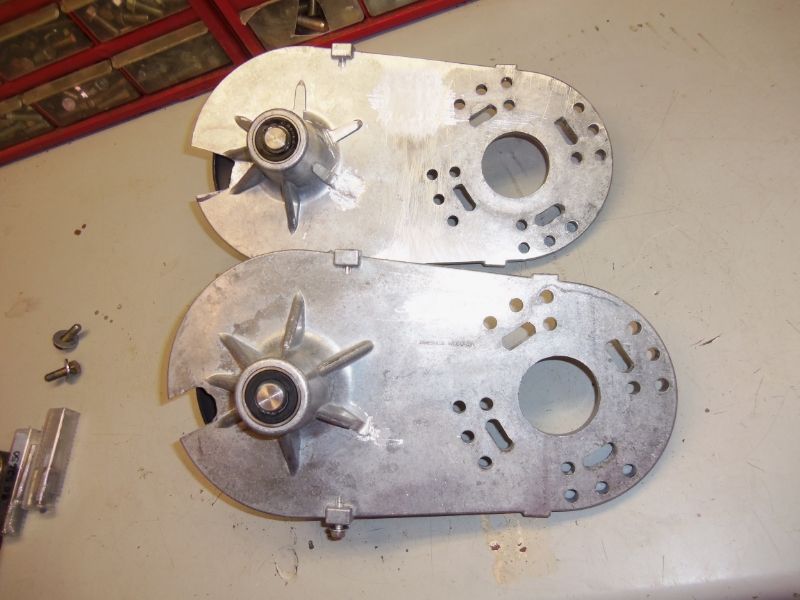

No, you're not seeing double. I now have TWO TAV2 kits.

I did not make the same mistake twice.

The only grinding on gussets I did was this little notch, needed to clear the rear oil fill cap and boss.

As opposed to the removal of 3 complete gussets on the bearing snout of the old TAV plate.

The notch to clear the frame tube is much tighter on the new TAV plate.

As opposed to the too wide slot on the old TAV plate.

Well, I am trying to be philosophical about this. As far as mistakes go, a $200 one is not bad. I have made much worse. So, now I have a complete spare TAV. So be it...

Seth K. Pyle