To start off, I am working on a Greyhound 212 with the governor intact and the governor spring cut to give me 4400rpm no-load. I have about 1.5-2 degrees timing advance by slotting the holes in the coil pack and moving it down. It has a Comet TAV2 that engages at 2200 rpm and accelerates at 3900 rpm. I also cut out all the gas tank emission BS.

Other than that, it's a bone-stock Greyhound 212.

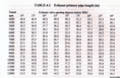

I want to make a scavenging header to target 3900rpm. I calculated 0.420" ID at 7' 3" long. I don't think that sounds correct at all, but I would have no trouble actually building something like that.

I don't think that sounds correct at all, but I would have no trouble actually building something like that.

I want to know if it's better to use this design or just make a free-flowing exhaust like everybody else likes.

Other than that, it's a bone-stock Greyhound 212.

I want to make a scavenging header to target 3900rpm. I calculated 0.420" ID at 7' 3" long.

I want to know if it's better to use this design or just make a free-flowing exhaust like everybody else likes.