Instead of just planning on 110 leaded gas, figure out what your compression ratio is going to be and then pick the fuel. Too much octane does offer a margin of safety, but it also costs power and money.

As for porting, it is generally advisable to leave the port floor alone, make the short-side radius as broad and sweeping as possible, leave a rough (~80-grit) finish in the intake port, and don't taper the ports any more than 8-10°.

1.) All the OHV utility engines I'm familiar with exhibit this phenomenon. The heads are die-cast instead of using sand cores and that requires that the port shapes allow for removal of the mold dies, so they can't really curve at all. Then the whole valve pocket and bowl is plunged with a mill cutter for speed/ease of manufacturing. It results in the port floor terminating at a sharp edge. In applications where performance is more important, the head can be die-cast with sand cores used to make complex port shapes.

2.) The broader you can make the radius transitioning the SSR to the valve seat, the better.

3.) Tapering the port into the seat is a subject of much debate, but what's more important is that 90% of what you'll read regarding 4v bike heads does not apply to 2v wedge or hemi designs. Furthermore, 5v designs like Yamaha used for a long time have very different porting considerations than even a 4v layout.

Lowering the port floor makes the SSR more critical because the charge has to make a larger change in direction. This also tends to cause flow separation at a lower velocity.

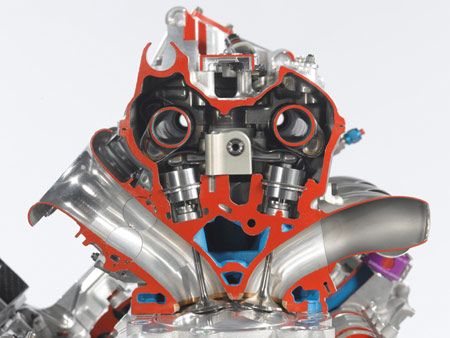

F1 engines, although an extreme example, utilize all the port velocity they can and the ports have such a large SSR that the ports are nearly straight. This is an older Toyota F1 engine cross-section to illustrate:

And this is one of Cosworth's designs:

You will get a variety of opinions on that. Shortening the guide protrusion reduces guide-to-valve contact area, valve stem support, and ultimately heat transfer. I prefer to leave the boss and guide in the port and instead streamline them as much as possible.

The loss of valve guide length can be addressed by using a longer guide and longer valves to "rob" length from the port side and put it under the valve spring.Then valvetrain geometry has to be checked and corrected as necessary.