I am not a porter but I have done enough to know that no matter how well a port flows it means nothing if the choke point is the pipe or intake/carb. You have to make it all work together! And if you build a good flowing head with a carb and pipe to match but pick a cam that never takes advantage of the head then to top it off have a clutch that doesn't engaged anywhere near the cams operating range you will have a pig.

And you can have swirl without a massive ramp you have port shape combustion chamber and boundary layer also. If you want to get picky think about lift at the valve and valve seat angles that will take advantage of low lift or high lift flow 30 degree vs 45 vs 50 ect. If you plan it out for what you have you will have a real firecracker. And I am just touching on this if any of the builders want to let their secrets out they will they make it look real easy but they are very good at making big power out of a utility engine.

And you can have swirl without a massive ramp you have port shape combustion chamber and boundary layer also. If you want to get picky think about lift at the valve and valve seat angles that will take advantage of low lift or high lift flow 30 degree vs 45 vs 50 ect. If you plan it out for what you have you will have a real firecracker. And I am just touching on this if any of the builders want to let their secrets out they will they make it look real easy but they are very good at making big power out of a utility engine.

So I have to continue to work through exactly how I will deal with this new head.

I appreciate your comments, and as I mentioned I have seen some rather interesting work done on one 210 head but that is it.

The only thing I can think of to put any swirl into this would be done in the bowl.

Probably how to shape one side and how deep to cut down VS the other side.

But as I you said if any of the builders want to open up and talk I am all ears.

Today did nothing but push some guides on an old 22cc head casting.

This is preparation for the big push on this new head.

But I am still up on the air on what I will do other than round off the short radius for now.

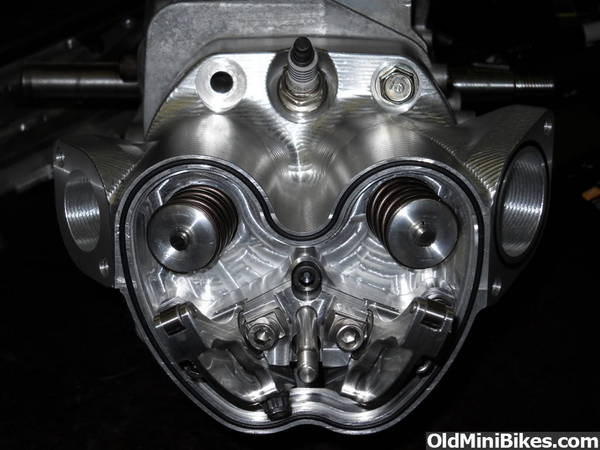

The only thing that looks like what I want to end up with is the big belmitt head.

Its not swirly and its a straight port with a quench.

So pass your eye across this Novaracer.

I was looking at this head for some ideas.

Getting warmer?

http://www.circletrack.com/featuredvehicles/ctrp_0706_chevrolet_r07_cylinder_heads/photo_05.html#

I was looking at this head for some ideas.

Getting warmer?

http://www.circletrack.com/featuredvehicles/ctrp_0706_chevrolet_r07_cylinder_heads/photo_05.html#

The point was to show the benefit of swirl, which is at low RPM should have mentioned that. Getting swirl depends on port configuration. On a non Hemi head it is a pretty straight shot so the area around the guide would have to have one side greater than the other and also going around the back. unfortunately you can't go too far or you are up into the spring pocket.

Shelbyclone

I'm wondering if my velocity probe could discern swirl? If for example I check the port across the top, middle and floor from right to left and velocity is higher on one side than the other (lets say top) would that indicate a possible swirl condition. (assuming I am checking near the valve at lifts above say .250?

I'm wondering if my velocity probe could discern swirl? If for example I check the port across the top, middle and floor from right to left and velocity is higher on one side than the other (lets say top) would that indicate a possible swirl condition. (assuming I am checking near the valve at lifts above say .250?

That would ultimately be manual mapping of the airflow path in the port and I don't know that measuring conditions in the port will tell you much about what's happening in the cylinder.

Swirl in the port isn't important IMO. It means that the air has to travel a longer path to cover a given distance. There is a finite amount of energy available to move that air, so I think the energy is better spent getting the air into the cylinder instead of generating rotation of it.

Too much swirl can also be a bad thing. Get the charge to change direction quickly enough and it can sling fuel out of suspension. OEM engines with swirl-producing ports usually don't flow well for high-performance applications. Have a look at the Toyota 22RE head. The intake ports generate a lot of swirl and the engine has great torque and fuel consumption, but lackluster power and not that much room to grow.

Swirl in the port isn't important IMO. It means that the air has to travel a longer path to cover a given distance. There is a finite amount of energy available to move that air, so I think the energy is better spent getting the air into the cylinder instead of generating rotation of it.

Too much swirl can also be a bad thing. Get the charge to change direction quickly enough and it can sling fuel out of suspension. OEM engines with swirl-producing ports usually don't flow well for high-performance applications. Have a look at the Toyota 22RE head. The intake ports generate a lot of swirl and the engine has great torque and fuel consumption, but lackluster power and not that much room to grow.

So pass your eye across this Novaracer.

I was looking at this head for some ideas.

Getting warmer?

R07 Cylinder Heads Twisted Port Photo 5

I was looking at this head for some ideas.

Getting warmer?

R07 Cylinder Heads Twisted Port Photo 5

That would ultimately be manual mapping of the airflow path in the port and I don't know that measuring conditions in the port will tell you much about what's happening in the cylinder.

Swirl in the port isn't important IMO. It means that the air has to travel a longer path to cover a given distance. There is a finite amount of energy available to move that air, so I think the energy is better spent getting the air into the cylinder instead of generating rotation of it.

Too much swirl can also be a bad thing. Get the charge to change direction quickly enough and it can sling fuel out of suspension. OEM engines with swirl-producing ports usually don't flow well for high-performance applications. Have a look at the Toyota 22RE head. The intake ports generate a lot of swirl and the engine has great torque and fuel consumption, but lackluster power and not that much room to grow.

Swirl in the port isn't important IMO. It means that the air has to travel a longer path to cover a given distance. There is a finite amount of energy available to move that air, so I think the energy is better spent getting the air into the cylinder instead of generating rotation of it.

Too much swirl can also be a bad thing. Get the charge to change direction quickly enough and it can sling fuel out of suspension. OEM engines with swirl-producing ports usually don't flow well for high-performance applications. Have a look at the Toyota 22RE head. The intake ports generate a lot of swirl and the engine has great torque and fuel consumption, but lackluster power and not that much room to grow.

I made more phone calls today trying to get a machine shop to do my machine work.

And again the answer is no.

I think I am going to put the head on a shelf and stay away from it until some point in the future there is both enough information to make some informed decisions and I can get some work done ( localy only I want to see what is being done to my specifications ).

And again the answer is no.

I think I am going to put the head on a shelf and stay away from it until some point in the future there is both enough information to make some informed decisions and I can get some work done ( localy only I want to see what is being done to my specifications ).