Ok, for the last month or so I have spent some time trying to find all the info I can about building a modded 5hp Briggs flathead. I have also spent some time gathering parts. The motor I have is a 5hp Briggs I/C flathead, with the sleeve and the 2 bearing on the crank.

I know that first and foremost if I remove the gov. like I am doing I will need a billet flywheel and connecting rod, which I have. The flywheel is stock size, and the connecting rod is 3.875'' from ARC.

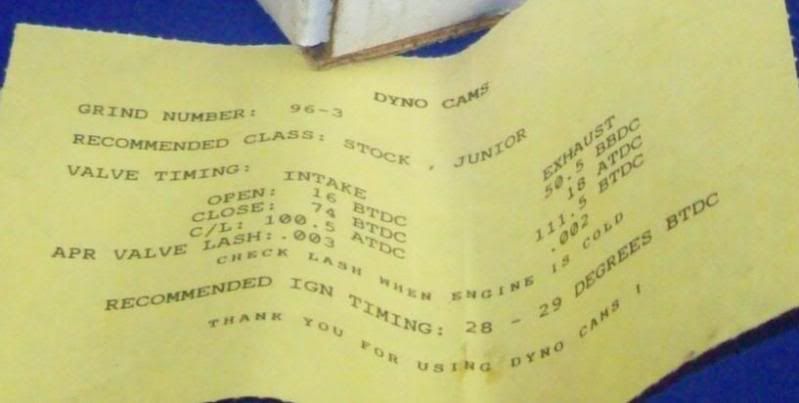

I also bought a 233ss cam. What kind of springs should I use with this cam? or do I need aftermarket springs? and will the stock valves be good enough?

Also, should I get billet lifters? and if so, would the +1.00" billet lifters be okay?

Okay, now what about the carb, can I just jet the stock Briggs carb to work? or should I get a raptor carb instead?

I know how to port/polish the block, clean up rough castings, trim the eyebrows, etc. but what about milling the head? If I trim the eyebrows to increase flow, would milling the head just be going backwards? or how much would be okay to take off?

I bought an advanced flywheel key kit from Riekens Racing, what degree key would be best to use on a motor like what I'm building?

I know I've asked alot of questions, but I really appreciate the help, because I want to make sure I get the right combination of parts so that I build the motor right.

Thanks in advance for the help. :thumbsup:

I know that first and foremost if I remove the gov. like I am doing I will need a billet flywheel and connecting rod, which I have. The flywheel is stock size, and the connecting rod is 3.875'' from ARC.

I also bought a 233ss cam. What kind of springs should I use with this cam? or do I need aftermarket springs? and will the stock valves be good enough?

Also, should I get billet lifters? and if so, would the +1.00" billet lifters be okay?

Okay, now what about the carb, can I just jet the stock Briggs carb to work? or should I get a raptor carb instead?

I know how to port/polish the block, clean up rough castings, trim the eyebrows, etc. but what about milling the head? If I trim the eyebrows to increase flow, would milling the head just be going backwards? or how much would be okay to take off?

I bought an advanced flywheel key kit from Riekens Racing, what degree key would be best to use on a motor like what I'm building?

I know I've asked alot of questions, but I really appreciate the help, because I want to make sure I get the right combination of parts so that I build the motor right.

Thanks in advance for the help. :thumbsup: