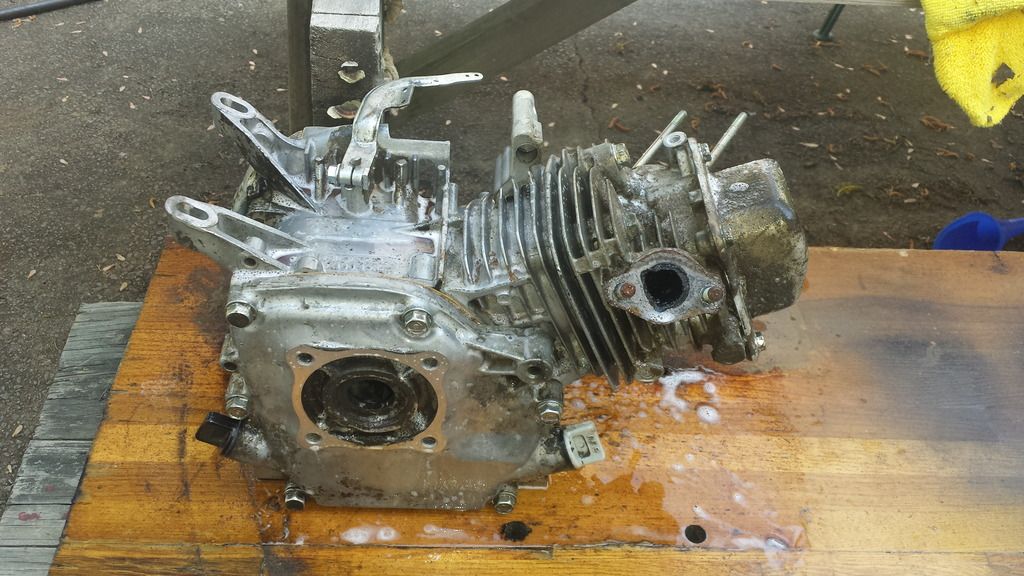

Ok so first of all i want to apologize to anyone for the stupid amount of questions ill end up asking during this process. This is the first engine i have broken all the way down and built back up. IF i can get it to start ill be very proud of myself. And i want to say thanks to jdblood202 for being in the area and helping me out. So yesterday i got this GX160. I didn't take any prior pictures (sorry) before we started taking her apart. She had NO compression but spark was there. So JB helped me take it apart step by step and look everything over. Lets say it wasn't very pretty but it wasn't near as bad as i expected. This is how it looks at the current moment

Slowly soaking with some degreaser, The block and head will get pressure washed tomorrow morning so i can start fresh. Cam was fine, Rod was fine, Piston and rings no so pretty. But the valves ill let the pro's make their suggestion

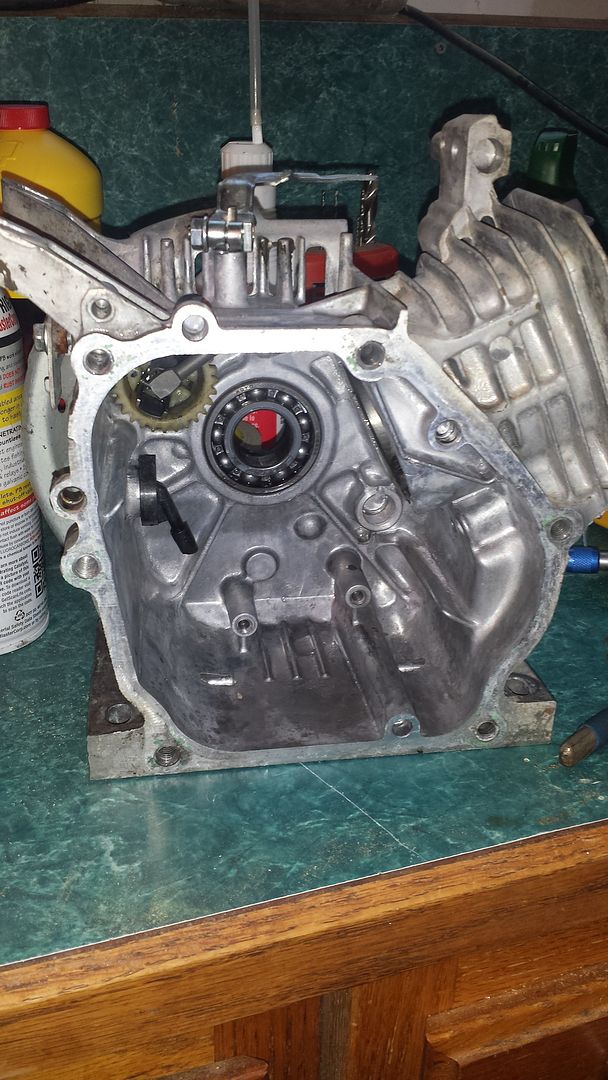

I already ordered a new gasket set and a new stock carb. But here is my first set of questions. This is what the cylinder bore looks like at the current moment. Ill take new pictures tomorrow once it is all washed but im trying to keep the engine close to or all the way stock. What should i do about the cylinder walls.

Like i said this if a first for me so ill be trying to learn as much as i can. Thanks everyone

Slowly soaking with some degreaser, The block and head will get pressure washed tomorrow morning so i can start fresh. Cam was fine, Rod was fine, Piston and rings no so pretty. But the valves ill let the pro's make their suggestion

I already ordered a new gasket set and a new stock carb. But here is my first set of questions. This is what the cylinder bore looks like at the current moment. Ill take new pictures tomorrow once it is all washed but im trying to keep the engine close to or all the way stock. What should i do about the cylinder walls.

Like i said this if a first for me so ill be trying to learn as much as i can. Thanks everyone