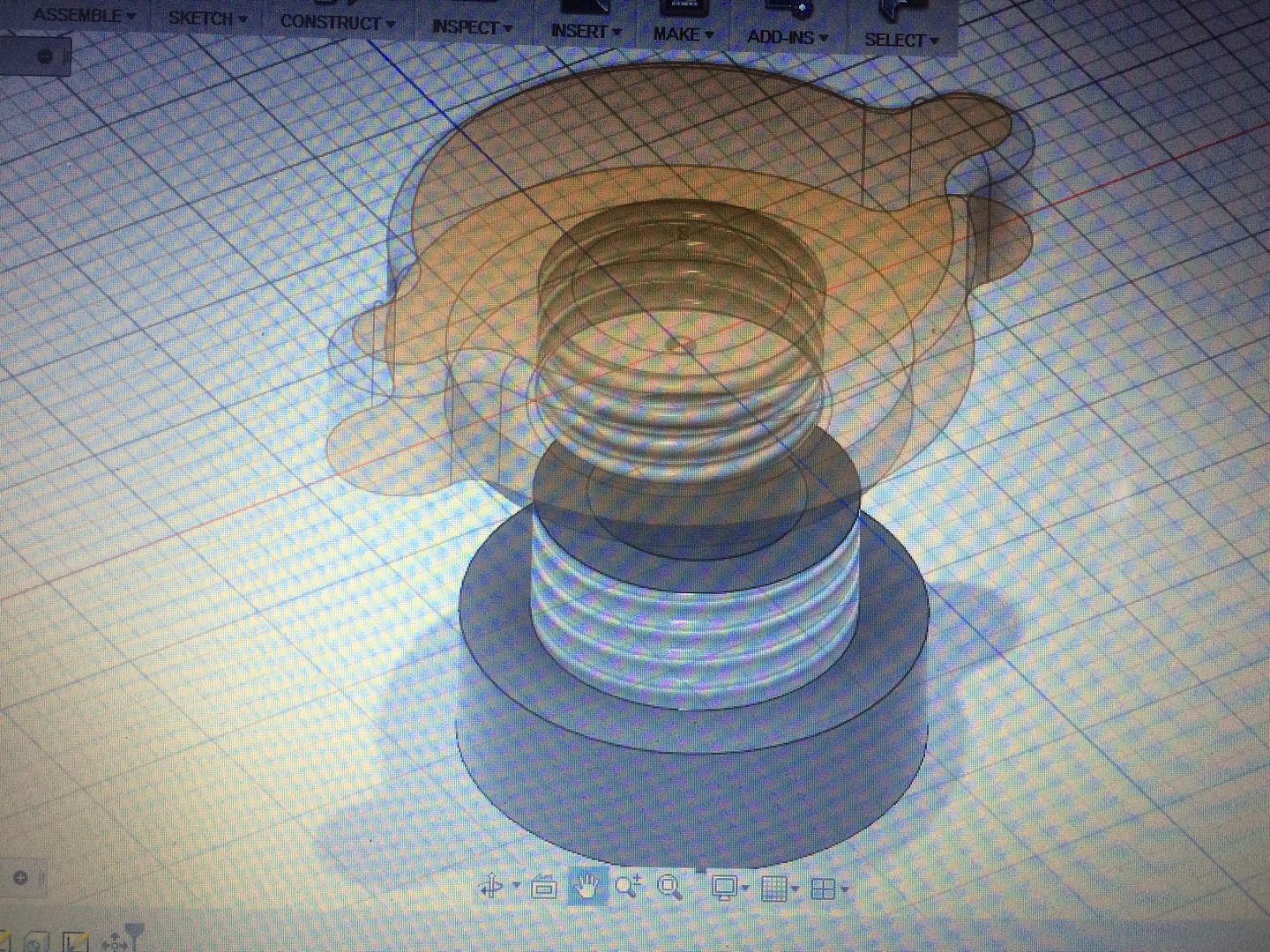

Decided to try my hand at playing with 3d programming and parts... so will post related progress in this thread... looking for a program to buy that isnt going to break the bank.. but also trying some free ones and figuring out how to convert it over to misc saved files... programs would be able to cut on most machines...

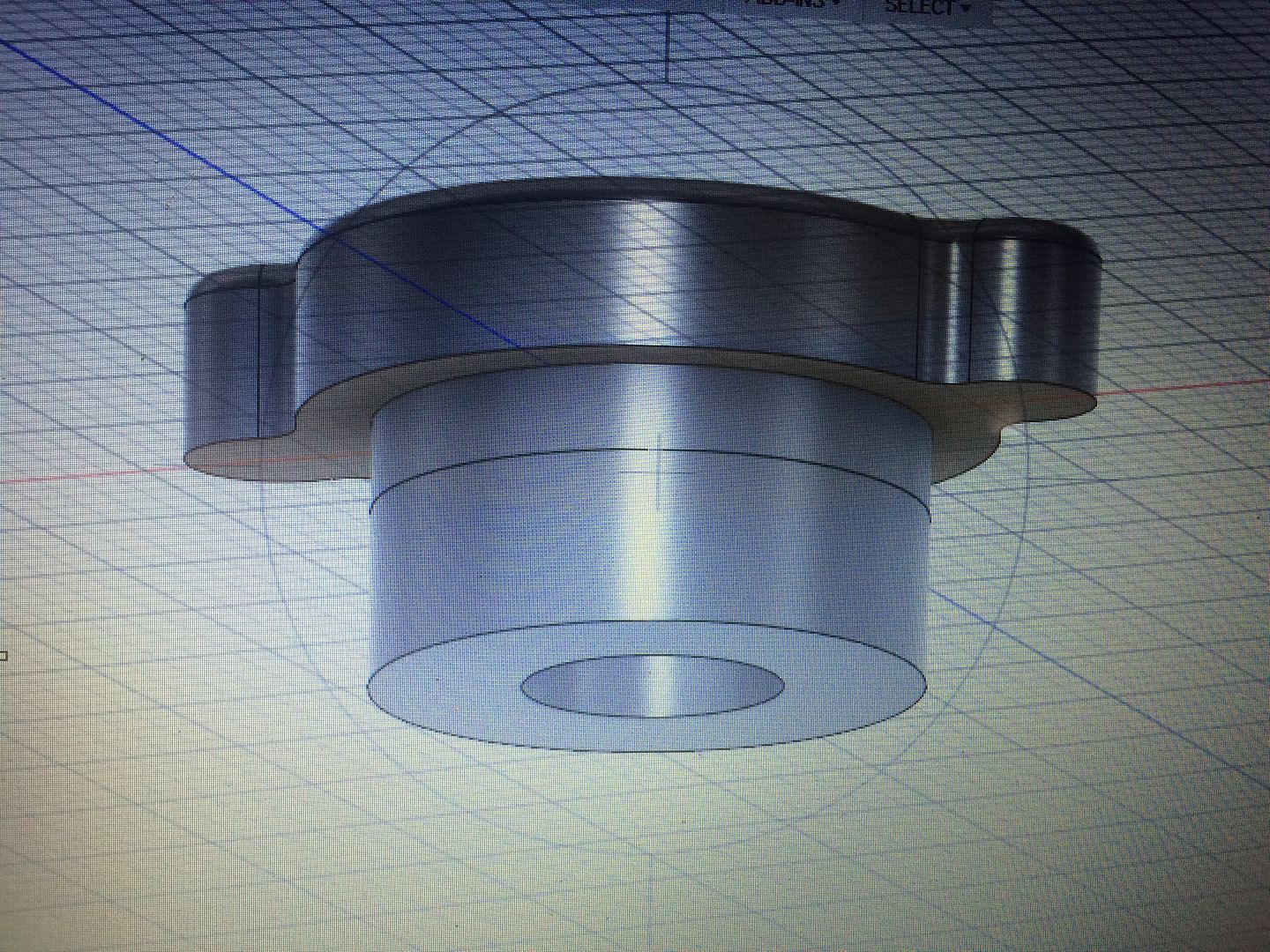

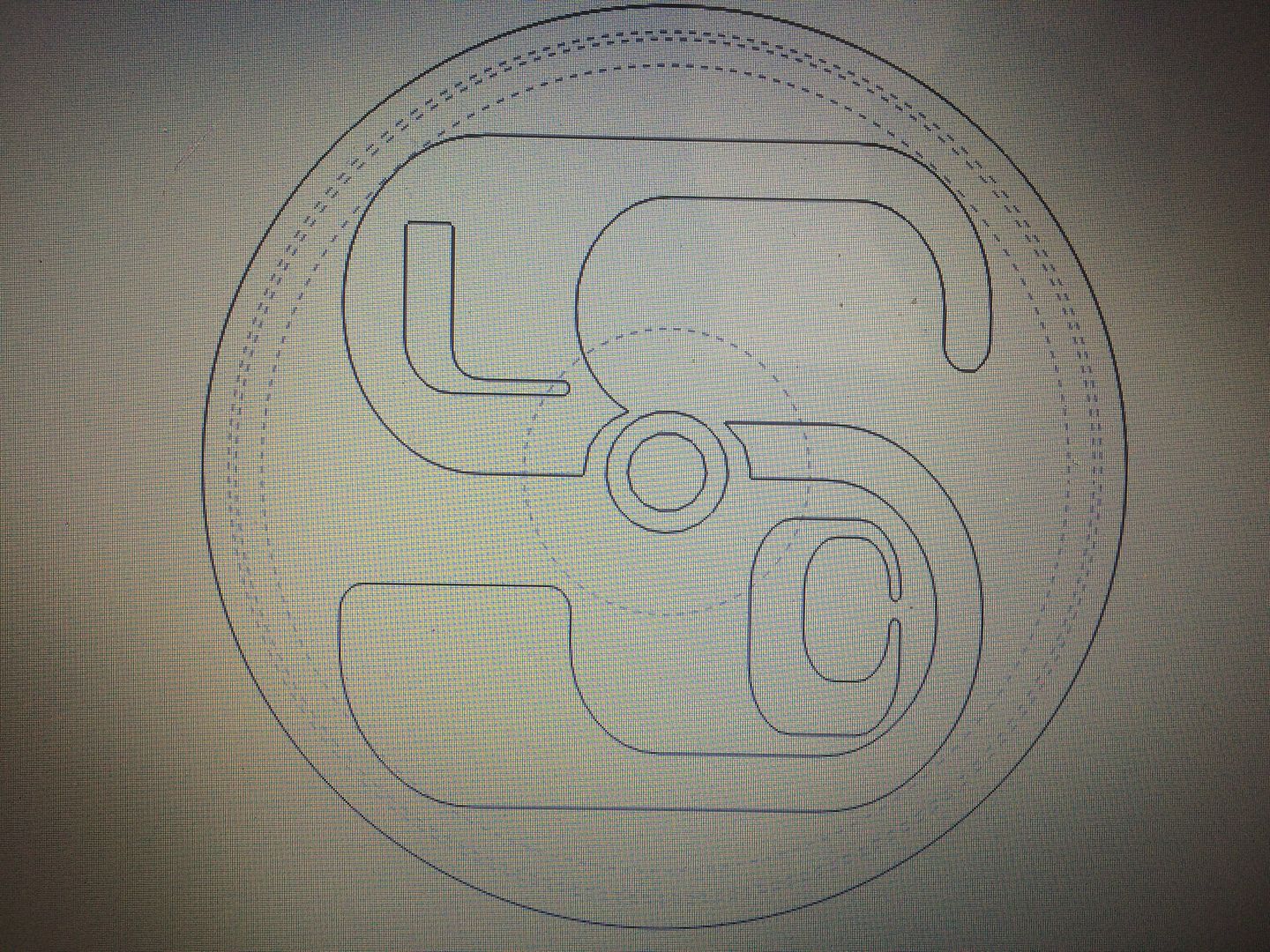

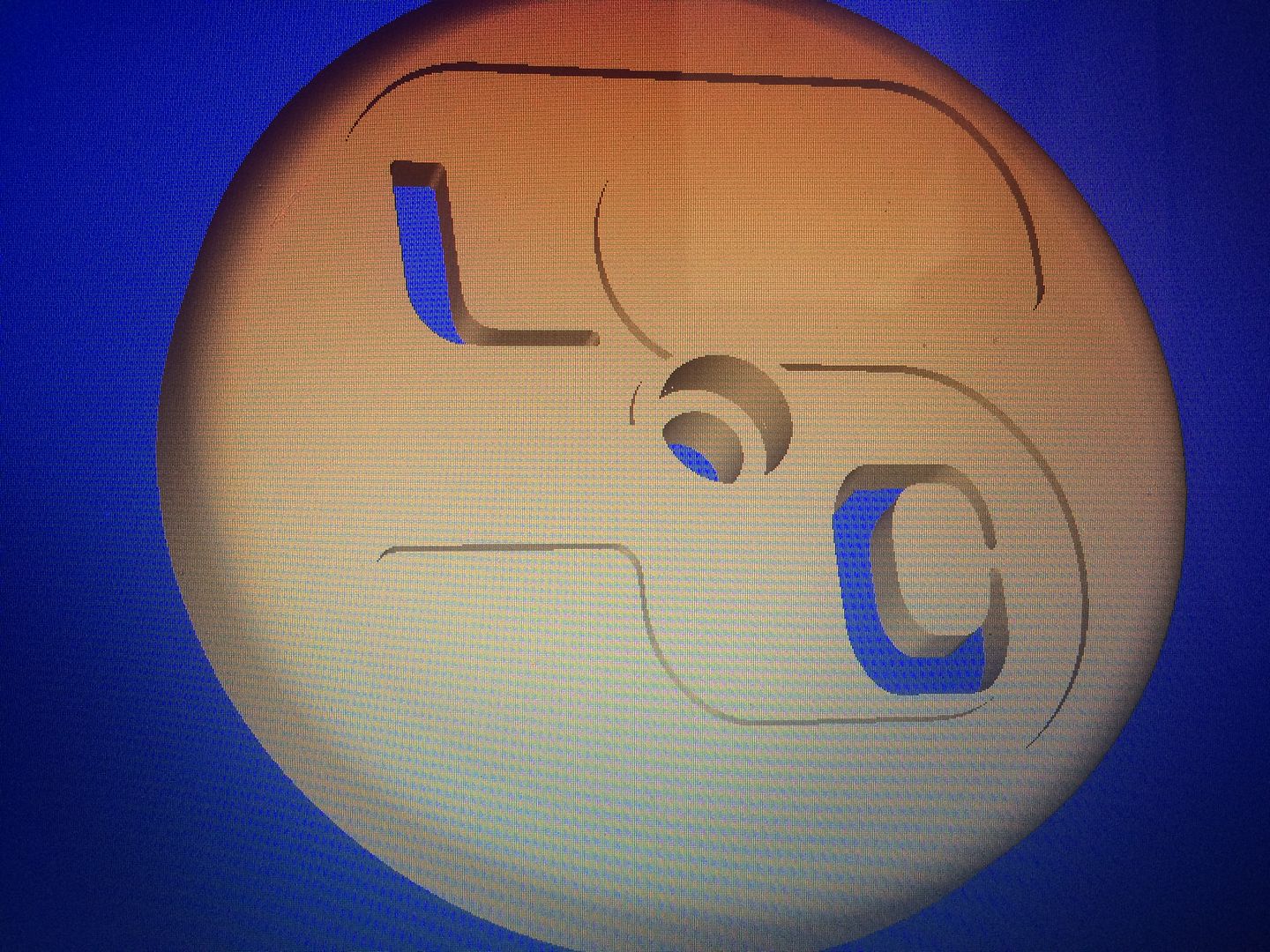

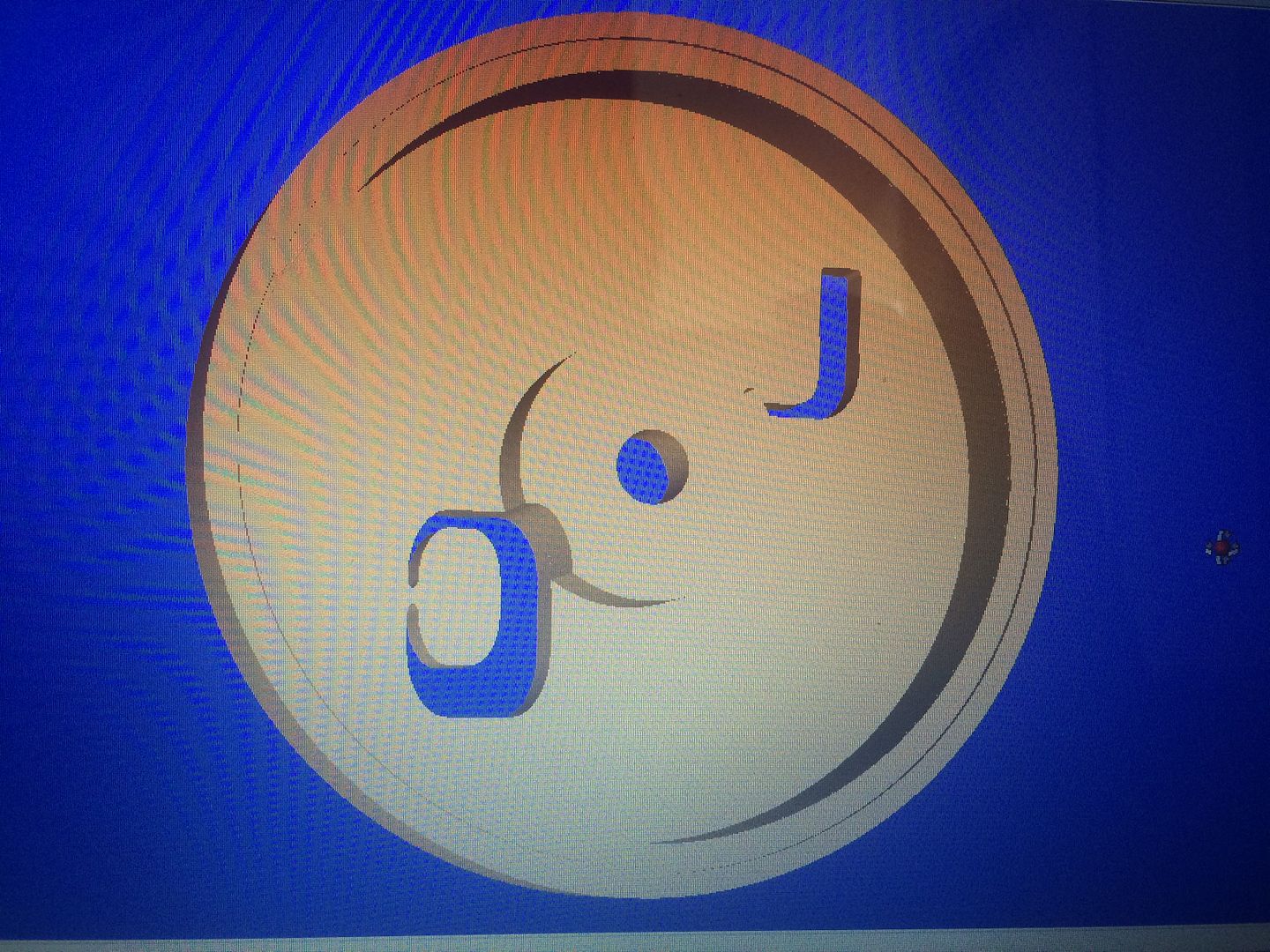

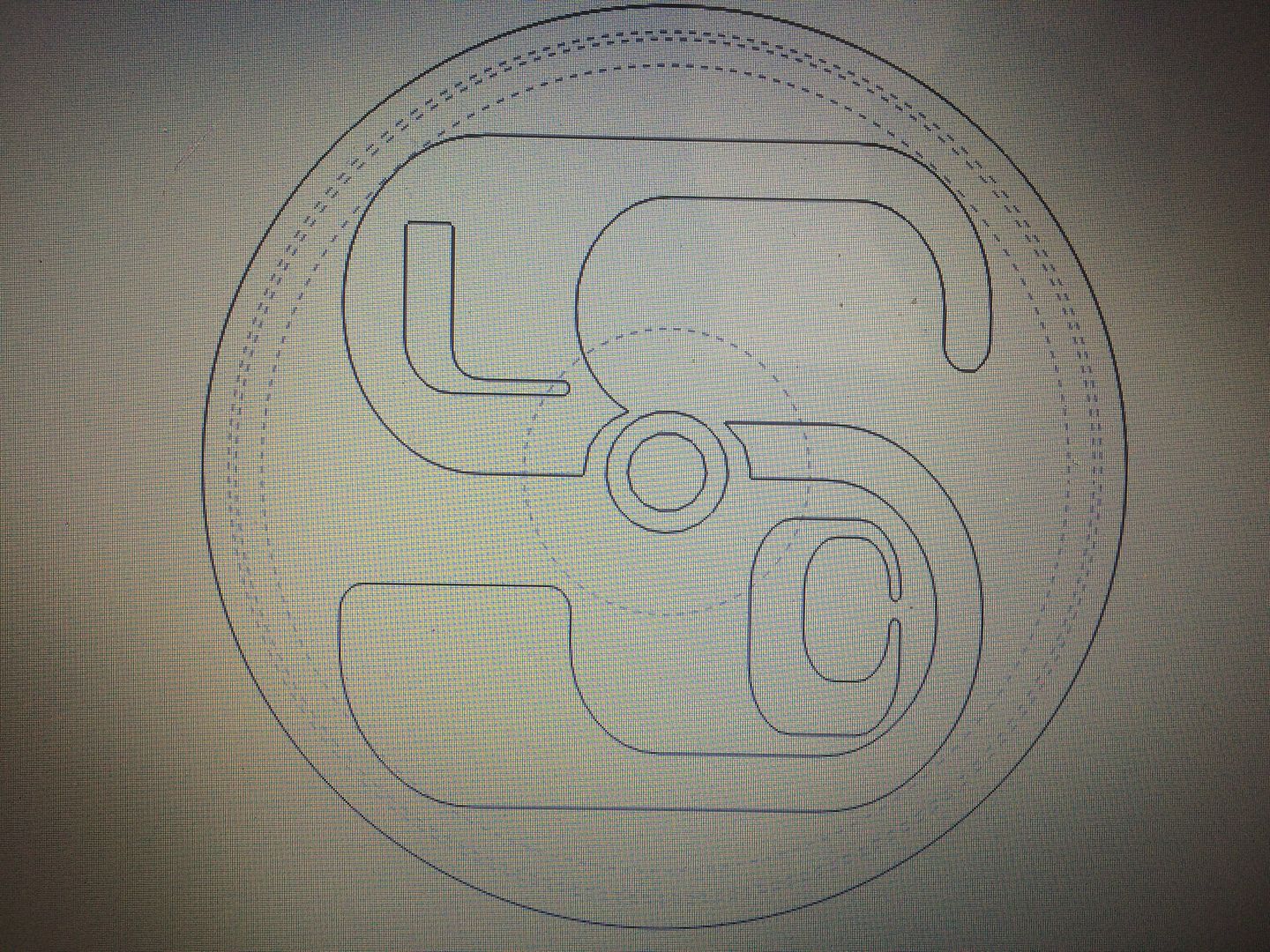

this first project if for some lighted end caps, i want to make for my first tig welding project... lots of firsts with this first one (for me)...

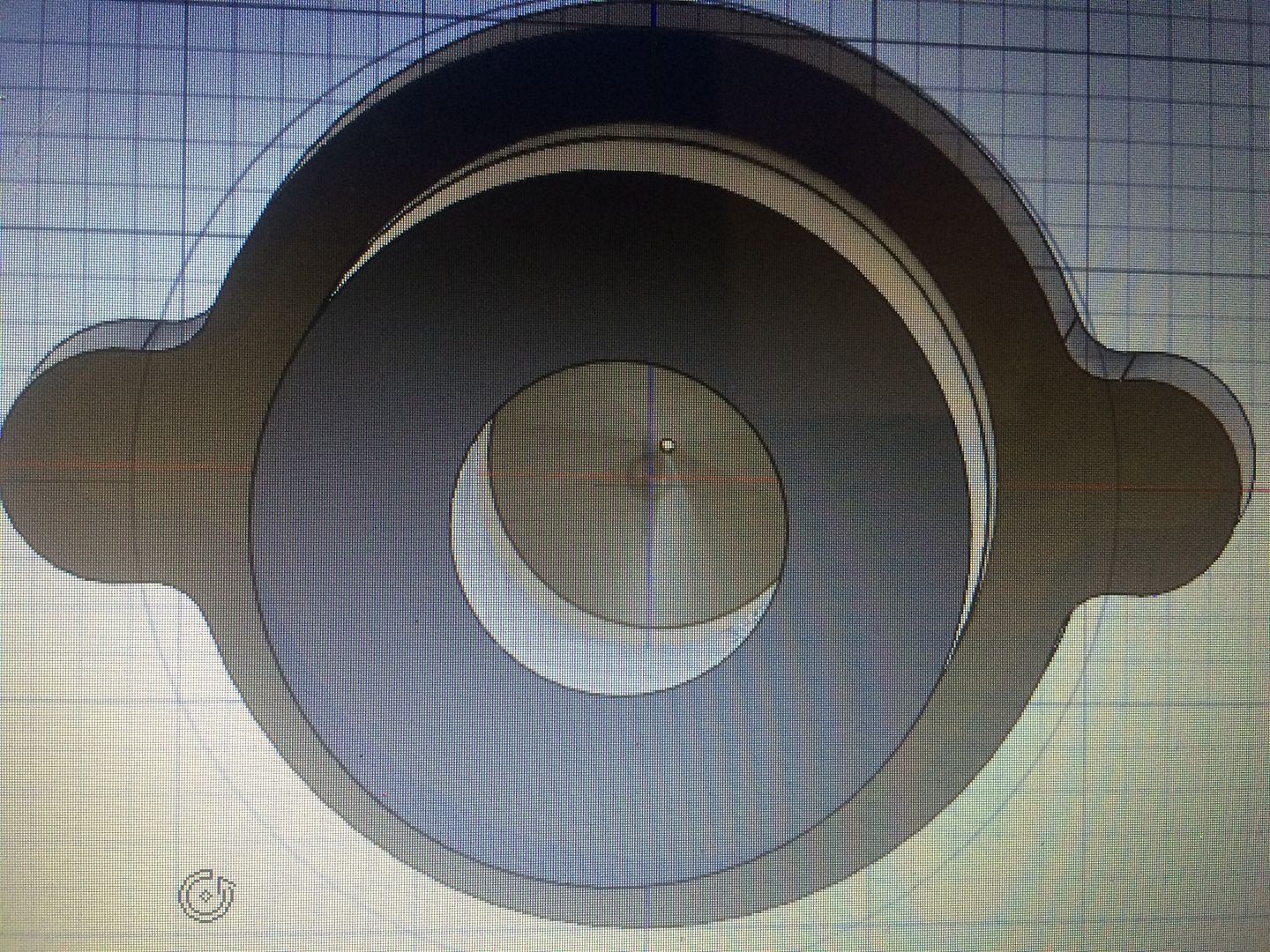

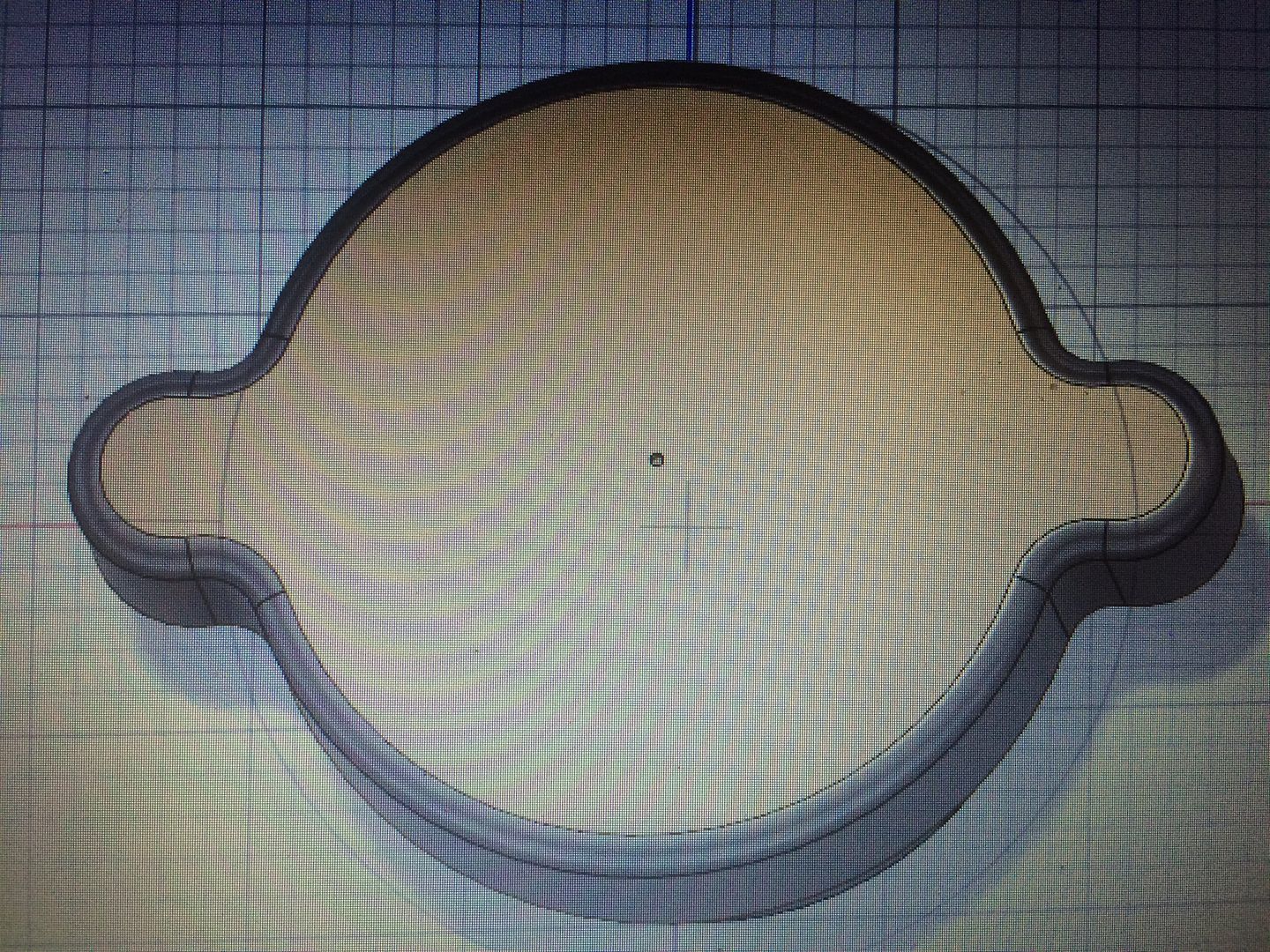

i out a groove in the bottom to accept a rubber oring... the s is recessed, i may trim out areas around the S shape so that i can light that up too... doing these two end caps as a test... in case people start liking some of the stuff i do and want something custom for themselves... im trying to learn any and everything i can, related to fabrication... and programming and letting a machine to the work, can sometimes be a great way to accomplish something, where you dont have all the skill or machinery to manually do it...

this first project if for some lighted end caps, i want to make for my first tig welding project... lots of firsts with this first one (for me)...

i out a groove in the bottom to accept a rubber oring... the s is recessed, i may trim out areas around the S shape so that i can light that up too... doing these two end caps as a test... in case people start liking some of the stuff i do and want something custom for themselves... im trying to learn any and everything i can, related to fabrication... and programming and letting a machine to the work, can sometimes be a great way to accomplish something, where you dont have all the skill or machinery to manually do it...