Ok I am in for round two lol

As many of you know I love old tractors and built a 1/3 scale Allis Chalmers last year so I have wanted to build another so what would be cooler than a baby John Deere model 40

It will use a snowblower auger drive for a rear end , and a 97cc doodle bug engine for power

the front wheels are 2.5o x 4 and the rears are 4.80 x 8 , boat trailer fenders to be cut up for rear fenders

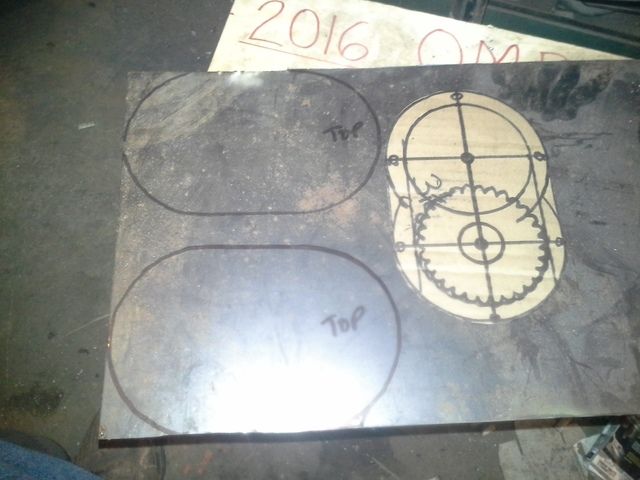

The rest of the parts will be fabricated as needed lol

My pile of parts

My Allis Chalmers

John Deere model 40

This build will take some time , lots of metal work to get the right look for the hood , grill etc.

As many of you know I love old tractors and built a 1/3 scale Allis Chalmers last year so I have wanted to build another so what would be cooler than a baby John Deere model 40

It will use a snowblower auger drive for a rear end , and a 97cc doodle bug engine for power

the front wheels are 2.5o x 4 and the rears are 4.80 x 8 , boat trailer fenders to be cut up for rear fenders

The rest of the parts will be fabricated as needed lol

My pile of parts

My Allis Chalmers

John Deere model 40

This build will take some time , lots of metal work to get the right look for the hood , grill etc.