Gilson Restomod

- Thread starter UnorthodoxCreat

- Start date

- Tags gilson h50 montgomery wards restomod

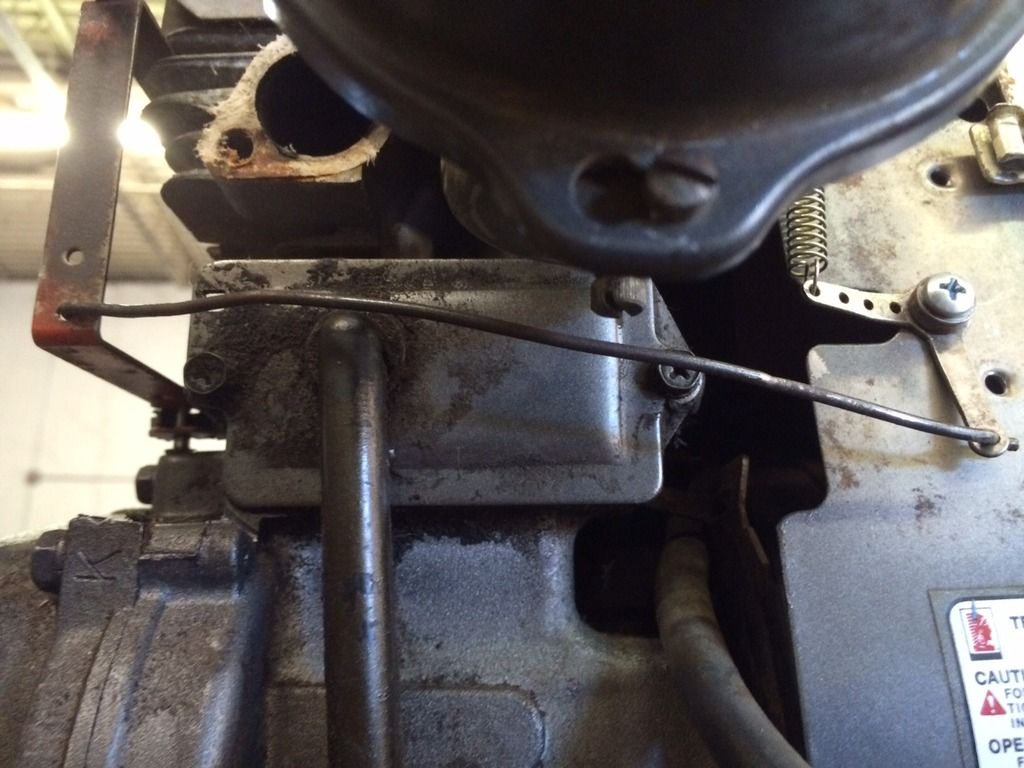

I started this morning getting the brake hooked up. Then it was on to the throttle. I purchased a used correct mini bike throttle so I need to get that installed. I removed the old throttle and created a template for the new mounting bracket.

Then drilled the new holes and welded up the old holes.

I installed all the brackets and created new linkages. Coat hanger works great for making linkages. I had to open up some of the holes a tiny bit for the rod to fit but it's stiff enough and bend to the shape you need. Can someone who has a stock H50 with this throttle setup tell me how long these to linkages are?

I just guessed on length when I made them and I'm not able to get the throttle to open very far. If someone could provide those dimensions it might save me a lot of trial and error.

Assembled

[video]https://youtu.be/48ApooeHb6g[/video]

My biggest issue right now is the throttle. My "fixed" original throttle isn't going to cut it. It's not near smooth enough in operation so I'm going to have to buy a new one. As stated above I'm not sure my linkage lengths are correct so that's not helping my throttle issue.

I'm also having problems with the 20 series. It won't sit and idle. The belt I have says 8 3/16-8 1/4" spacing between the center of the crankshaft and the center of the jackshaft. I've got the engine almost back to 8 1/8" and the belt is still catching at idle. I don't know if it's because my driver is old and still needs cleaned up, if my idle is too high or if I need to move the engine back farther.

Other than that the only other issue is the fuel petcock leaks when open. I tested it closed to make sure the tank didn't leak but I'll have to replace that because it leaks pretty good. I rode it around my parking lot at work. I'll try and get my wife to take a video tomorrow. To get much speed I have to work the throttle with my hand down between the frame with makes driving a bit tough.

Then drilled the new holes and welded up the old holes.

I installed all the brackets and created new linkages. Coat hanger works great for making linkages. I had to open up some of the holes a tiny bit for the rod to fit but it's stiff enough and bend to the shape you need. Can someone who has a stock H50 with this throttle setup tell me how long these to linkages are?

I just guessed on length when I made them and I'm not able to get the throttle to open very far. If someone could provide those dimensions it might save me a lot of trial and error.

Assembled

[video]https://youtu.be/48ApooeHb6g[/video]

My biggest issue right now is the throttle. My "fixed" original throttle isn't going to cut it. It's not near smooth enough in operation so I'm going to have to buy a new one. As stated above I'm not sure my linkage lengths are correct so that's not helping my throttle issue.

I'm also having problems with the 20 series. It won't sit and idle. The belt I have says 8 3/16-8 1/4" spacing between the center of the crankshaft and the center of the jackshaft. I've got the engine almost back to 8 1/8" and the belt is still catching at idle. I don't know if it's because my driver is old and still needs cleaned up, if my idle is too high or if I need to move the engine back farther.

Other than that the only other issue is the fuel petcock leaks when open. I tested it closed to make sure the tank didn't leak but I'll have to replace that because it leaks pretty good. I rode it around my parking lot at work. I'll try and get my wife to take a video tomorrow. To get much speed I have to work the throttle with my hand down between the frame with makes driving a bit tough.

I'll get the measurements for you tomorrow when I go to my shop, unless someone else post them before I can. I bought the more expensive 1"

throttle from OldMiniBikes warehouse, nice action and is matches the size of the bike looks wise.

Great work on the build, I've enjoyed following someone else do a Wards bike.

throttle from OldMiniBikes warehouse, nice action and is matches the size of the bike looks wise.

Great work on the build, I've enjoyed following someone else do a Wards bike.

I'll get the measurements for you tomorrow when I go to my shop, unless someone else post them before I can. I bought the more expensive 1"

throttle from OldMiniBikes warehouse, nice action and is matches the size of the bike looks wise.

Great work on the build, I've enjoyed following someone else do a Wards bike.

throttle from OldMiniBikes warehouse, nice action and is matches the size of the bike looks wise.

Great work on the build, I've enjoyed following someone else do a Wards bike.

Would anyone out there have a 20 series driver they could measure for me? I found some info that indicates that older drivers may have used some sort of spacer so they could use a 3/4" belt. It just seems like my driver pulley is to tight on the belt. It won't slip at idle over even turning the engine over by hand. I bought this driver used and it certainly looks old.

Tonight was a pretty good night. I had made and installed some new throttle linkages according to slingshot's dimensions yesterday. That long with the new throttle I got and installed today greatly improved the throttle action. I also installed the new gas tank peacock with solved my fuel leak problems. I was still having problems with the driver pulley always catching on the belt. I confirmed the bronze bushing was moving fine but still installed a new bushing. I took the driver apart and cleaned and lubed that but it still didn't solve my problems. I did some reading that indicated that drivers made prior to 1994 needed a spacer to run a 3/4" belt. I don't know how old my driver is or if interpreted what I read correctly but I decided to try making a spacer anyways since I had little to lose. I found a big old washer that was about 1/8" thick and had a 3/4" ID. I cut and shaped the outside down till it was small enough it wouldn't touch the belt or the bronze bushing. That solved my problem. Now the bike will sit and idle without driving the rear well but it still run well and shifts into high gear.

My one problem I need to solve is the governor. It's kicking in too soon and I'm not sure how to adjust it. I was able to ride around my parking lot but the seems to be surging, bouncing off the governor. I'm not sure how or where to adjust. If it can get that fixed I'm ready to break the bike down for powder coating.

My one problem I need to solve is the governor. It's kicking in too soon and I'm not sure how to adjust it. I was able to ride around my parking lot but the seems to be surging, bouncing off the governor. I'm not sure how or where to adjust. If it can get that fixed I'm ready to break the bike down for powder coating.

Did you get the rods and springs in the correct holes? Another thing you may want to check is that the governor rod is properly aligned at idle. If you need to mess with any of these, and need to test, make sure the rear wheel is off the ground when you start the bike(I speak from a bad experience). I solved my surging problem by getting the governor properly aligned to idle.