Delray was kind enough to offer me another Gilson, this time a Trail Bike, while we were at Windber. Brian said the forks were a little rusted but otherwise pretty much there. This bike has the rear fender mount, original gas tank, engine chain tensioner and most importantly, a complete brake assembly. The spoked wheels are in pretty good condition, though I'm going to have to find some spokes for one of the wheels. The drive sprocket is in great shape. This is a torque converter bike, so this will be my first experience with one. I've already been in contact with Unorthodox and RCGuy to get measurements for the inside mount jackshaft plates that are missing. My welder has parted with some 3/16" square tubing for the brackets and I ordered metal to make a couple of brake assemblies (one for Copperhead, in particular).

Gammatag was parting out a 323, so I grabbed a bunch of parts including a kick stand, solid front forks, and a partial brake assembly. I also grabbed the wheels for a future build. Harley's Poppa made me a great deal on a Tecumseh H60, and Joe51 is shipping a throttle control kit to me. Need to talk to Mr. Wulf about a custom exhaust to mimic the original. So, won't be entirely correct with the H60, but torque is torque and I hear these run pretty strong.

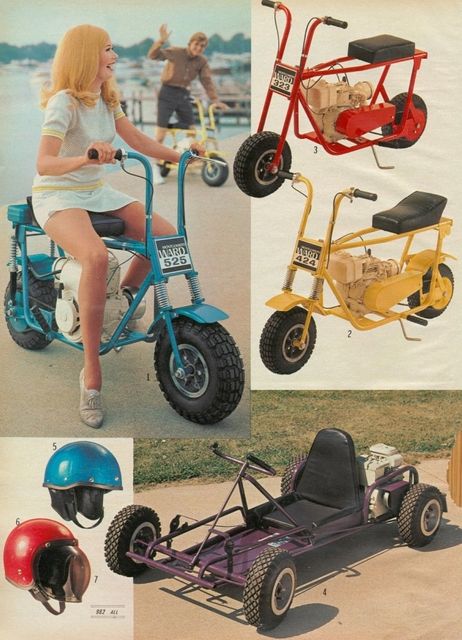

Below are pics of what we are starting with (well, most of the parts).

Gammatag was parting out a 323, so I grabbed a bunch of parts including a kick stand, solid front forks, and a partial brake assembly. I also grabbed the wheels for a future build. Harley's Poppa made me a great deal on a Tecumseh H60, and Joe51 is shipping a throttle control kit to me. Need to talk to Mr. Wulf about a custom exhaust to mimic the original. So, won't be entirely correct with the H60, but torque is torque and I hear these run pretty strong.

Below are pics of what we are starting with (well, most of the parts).

Attachments

-

2.4 MB Views: 107

-

3.9 MB Views: 134

-

3.6 MB Views: 100

-

3.4 MB Views: 100