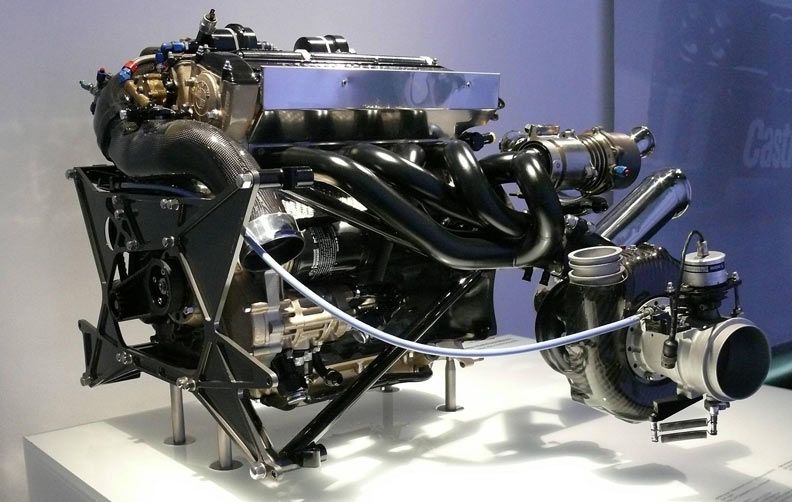

I never knew one could mount a throttle directly to the turbo inlet. No problem with that seeing temperatures from 500-1000 C? Gasoline boil off temp as you know is a tenth of that.

Silly to even ask that, while looking at such a stellar piece of engineering and fabrication Kenny. Just outstanding.

Silly to even ask that, while looking at such a stellar piece of engineering and fabrication Kenny. Just outstanding.

I never knew one could mount a throttle directly to the turbo inlet. No problem with that seeing temperatures from 500-1000 C? Gasoline boil off temp as you know is a tenth of that.

BMW put a huge throttle body on the compressor inlet with their M12/M13 turbo F1 engines in the mid '80s, presumably to reduce lag and eliminate the blowoff valve.

I tried it with a GT15 turbo, but the dynamic compressor seal wasn't able to hold the oil back under closed throttle(typical of dynamic seals).

Shelby and Kenny, I erred in an earlier post on AFR's. I asked the kid yesterday what he was seeing on boost, and he said from 11.5 to 14 depending where he was at with the shifts, as it's hard to read fluctuating LED while driving it that hard. Says he gets a smoother acceleration near 12, but power output feels about the same up to 14. (No dyno) Just wanted to fix that.

Well guys i got a good few hours machining in between going to see family etc, i hope you all had a good christmas

I got the front hubs and disc mounted to the front wheel, Billet rear wheel mounts ( Still need some more weight taking out of them ), Bottom of the base plate and aswell as the jackshaft housing and support

I have machined cutouts into the bottom of the base so the big tabs im going to tig onto the frame will locate and take the stress rather than the bolts

I got the front hubs and disc mounted to the front wheel, Billet rear wheel mounts ( Still need some more weight taking out of them ), Bottom of the base plate and aswell as the jackshaft housing and support

I have machined cutouts into the bottom of the base so the big tabs im going to tig onto the frame will locate and take the stress rather than the bolts

As a fellow cnc machinist, im telling you guys, this is amazing work! I gave the ecotrons kit a try as well but gave up on it.

Heres me and my bike. I never could get it to work with their hall sensor. I tried a gy6 pickup and this video is the result. Always cutout at 6800rpms

http://m.youtube.com/watch?v=c6i0-BoZiro

http://m.youtube.com/watch?v=c6i0-BoZiro

Last edited:

Heres me and my bike. I never could get it to work with their hall sensor. I tried a gy6 pickup and this video is the result. Always cutout at 6800rpms

http://m.youtube.com/watch?v=c6i0-BoZiro

http://m.youtube.com/watch?v=c6i0-BoZiro

have the max rpm in the ecu set to higher than 6800rpm?

using the magnet what is provided with the hall sensor (around 12mm Dia)?

sensor close enough to the magnet?

using the magnet in the stock flywheel?

Max rpm set at 8500, flipped the magnet in my raceseng flywheel over to the proper pole. Definately close enough to the flywheel. I made abracket on the mazak with the m12x1.0 thread. Mounted between the stock coil bolts. Dont want to hijack your thread.

http://s174.photobucket.com/user/Chevy4x4722000/media/Mobile Uploads/Video12151854.mp4.html

http://s174.photobucket.com/user/Chevy4x4722000/media/Mobile Uploads/Video12151854.mp4.html

Last edited:

Max rpm set at 8500, flipped the magnet in my raceseng flywheel over to the proper pole. Definately close enough to the flywheel. I made abracket on the mazak with the m12x1.0 thread. Mounted between the stock coil bolts. Dont want to hijack your thread.

Video12151854.mp4 Video by Chevy4x4722000 | Photobucket

Video12151854.mp4 Video by Chevy4x4722000 | Photobucket

Only thing i can think of is these hall sensors are designed to count teeth on a spur gear and maybe the stock magnet being around 5-10 times as wide maybe sending too long of a signal at high rpms what the ecu is setup for?

Max rpm set at 8500, flipped the magnet in my raceseng flywheel over to the proper pole. Definately close enough to the flywheel. I made abracket on the mazak with the m12x1.0 thread. Mounted between the stock coil bolts. Dont want to hijack your thread.

I think this could be the problem. When I tried triggering off of a stock flywheel magnet with a VR sensor, the RPM reading was extremely erratic because the magnet was causing two trigger signals right next to each other followed by a long pause after the magnet passed. I bet you would find that the ECU is logging a peak RPM that is much higher than actual. I'm not sure why it completely stalls though. Rev limiter type and settings maybe?

I agree, below is the magnetic field of a normal magnet, you can see that each end of the magnet the field is pushed out rather than together like in the middle, what maybe happening is with a stock magnet being longer than the hall sensor usually works with at each end of the magnet it is picking up a trigger signal, it would be intresting to see what rpm on the laptop aswell as a tacho around the sparkplug wire displays at high rpm

"For some engines, such as Honda GX160, GX390, or similar, the stock magnet is North polarity. And the some engines, such as Gx35, the stock magnet is South polarity.

Our Hall Effect Sensor is by default South-Pole Magnet trigged.

If you install this Hall sensor to an engine which has a North-pole magnet, you will have 2 pulses per revolution, one at the leading edge of the magnet; one is at the trailing edge. This will confuse the ECU and you may not even able to start the engine. You may start the engine, sometime, but the running may be unstable or stall at high RPM.

To fix this, we can provide a North Pole Hall effect sensor as the pick-up sensor, so you don’t need install an extra South Pole magnet. But you must tell us before the shipping of the EFI kit. So we can replace the S-pole Hall sensor with a N-pole sensor."