Tecumseh Connecting Rods

- Thread starter roccosbike

- Start date

- Tags connecting rods tecumseh

No this is an early model engine and they used a lot smaller rod (journal wise)it has the small aluminum flywheel. I believe this engine is a 1970 it has a steel sleeve cylinder and a compression release cam in it. Its like the Bungholio motor. its like .860 where the connecting rod bolts on the crank about the same length though but I didn't confirm any of this just yet. I thought I would ask you guys, who knows somebody might have done it already.

roccosbike

just wondering is this a side exhaust engine or rear and want cam where you thinking of using?

just wondering is this a side exhaust engine or rear and want cam where you thinking of using?

i think i found the bore size 2 1/2 sound right? same as a 4hp but has a shorter stoke 1 27/32 = 1.843+

if your mains are the same as a 4hp crank? you could stuff a points 4hp crank and the factory 4hp aluminum flywheel.

now you can use a billet rod all day. the other problems you might have. thats if the first part works and fits correct?

if the steel sleeve will let you bore out to a 2.625 bore? or at that point remove the steel sleeve(because its to small to bore out)and you still have enough room to stuff a 2.625 piston?

your engine would go from a 9.06 cu to over 10 cu

now if you have past all thoses problems?

you could install a stiffer spring. i believe a briggs animal #15+ with some aftermarket retainers and locks. then you won't get any valve floating with the stock cam and the springs won't be to stiff and eat up the cam. i would think at that point you could get that engine to spin 4500+ all day.

now if all that did work...big if? you could get a after market cam . for example a dyno 245 cam. now you would have to reverse the intake and the exhaust set up and install a larger valve that use to be the exhaust side and is now your intake( i can see you hanging a small 20 or 22 mikuni on it:laugh:....all day), remember the 4hp and 5hp has the factory exhaust on the right,so the cams are different then yours.

you could have alot of fun with that little flathead motor if you could get that crank and piston size to fit. also if your block has enough material like a hs 5hp motor does? you could bore it out to a 2.805 now your cu.in. is getting real BIG

just think what kind of power you would have with that little side popper.....:thumbsup: you would be the coolest flathead kid

on the block and the fastest..........

if your mains are the same as a 4hp crank? you could stuff a points 4hp crank and the factory 4hp aluminum flywheel.

now you can use a billet rod all day. the other problems you might have. thats if the first part works and fits correct?

if the steel sleeve will let you bore out to a 2.625 bore? or at that point remove the steel sleeve(because its to small to bore out)and you still have enough room to stuff a 2.625 piston?

your engine would go from a 9.06 cu to over 10 cu

now if you have past all thoses problems?

you could install a stiffer spring. i believe a briggs animal #15+ with some aftermarket retainers and locks. then you won't get any valve floating with the stock cam and the springs won't be to stiff and eat up the cam. i would think at that point you could get that engine to spin 4500+ all day.

now if all that did work...big if? you could get a after market cam . for example a dyno 245 cam. now you would have to reverse the intake and the exhaust set up and install a larger valve that use to be the exhaust side and is now your intake( i can see you hanging a small 20 or 22 mikuni on it:laugh:....all day), remember the 4hp and 5hp has the factory exhaust on the right,so the cams are different then yours.

you could have alot of fun with that little flathead motor if you could get that crank and piston size to fit. also if your block has enough material like a hs 5hp motor does? you could bore it out to a 2.805 now your cu.in. is getting real BIG

just think what kind of power you would have with that little side popper.....:thumbsup: you would be the coolest flathead kid

on the block and the fastest..........

They did make them (billet rods for the small frame H) long time back, only one I have ever seen was in an old modded 1/4 midget engine that came up on here a year or so ago.

the HS parts wont cross with any of the H until the 80's so your block wont apply. They did start to open up the crank journals around the timing change thats noted in the manuals like 1983/84 and up into the electronic ignition era. Some of them at that point have the larger rod journal as well and use the HS rod. The Billet HS rod I have wont clear the front of the case and its too much to trim out of the rod, I think some clearencing is also needed (not much) coming up to pass the cam as well, Been awhile since I was trying parts out and I gave up once I knew I was going to have to knock a hole in the case and have it welded up. At that point the taper of the cranks are all late model steel flywheel specific though, so if you want to keep it "old school" you have to source an early HS40 flywheel, and pre 1981 HS crank in order to fit the early shrouds on.

the HS parts wont cross with any of the H until the 80's so your block wont apply. They did start to open up the crank journals around the timing change thats noted in the manuals like 1983/84 and up into the electronic ignition era. Some of them at that point have the larger rod journal as well and use the HS rod. The Billet HS rod I have wont clear the front of the case and its too much to trim out of the rod, I think some clearencing is also needed (not much) coming up to pass the cam as well, Been awhile since I was trying parts out and I gave up once I knew I was going to have to knock a hole in the case and have it welded up. At that point the taper of the cranks are all late model steel flywheel specific though, so if you want to keep it "old school" you have to source an early HS40 flywheel, and pre 1981 HS crank in order to fit the early shrouds on.

yes, the 5.5 billet rod 3.484 i have notes in the past will touch the camshaft between the lobes. material will need to be taken off the cam(very little).

markus, are you talking about the rod that cam in karl's engine ? that one looks to have no dipper and has bearings.

https://www.oldminibikes.com/forum/tecumseh/120872-performance-stock.html

markus, are you talking about the rod that cam in karl's engine ? that one looks to have no dipper and has bearings.

https://www.oldminibikes.com/forum/tecumseh/120872-performance-stock.html

markus, does the billet rod dipper hit the front cast. also are you saying the mains bearings are to small.

sounds like a person almost needs to have a newer side popper that came with the newer ignition and then you can maybe do the modifications i mention early.

sounds like a person almost needs to have a newer side popper that came with the newer ignition and then you can maybe do the modifications i mention early.

One of these rods:

Thats in a late model 80's H35 sidepopper I have, which came with large journal crank and HS rod factory (but still has the equal sized valves unlike the really late models where they shrunk the exhaust valve down).

If you compare an H engine and an HS you can see they added a little hump in the case on the HS, On the later H engine the hump still is not there. But the the stock HS style rod does clear, but not enough for the aftermarket rod. They may have altered that section slightly to give enough space on the later version but its not very noticeable if they did, I can't test an HS rod in the early small journal engine blocks due to not being able to get a crankshaft in there with the right size journal. So if you were going to go as far as boring out the flywheel side journal and use a larger journal sidecover on an early engine you may have a slight clearence problem at the face even with a stock rod to contend with as well.

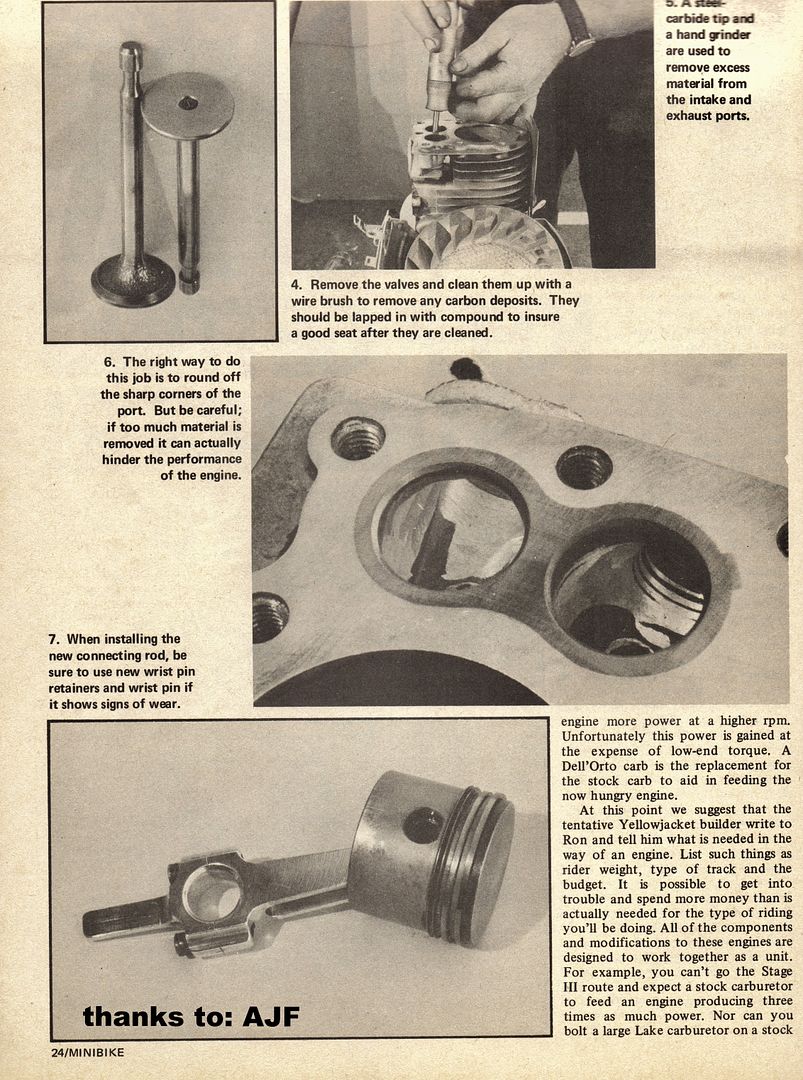

And yes the one example Billet rod I was referring to was the one in that engine Karl had. that one was in an oil pump engine, so no dipper and had actual bearings, heres what the standard oil slinger looked like that Ron's used for the small frame H engines:

markus

is there not enough material. ? something casted different in that area too. have any pictures markus.....:thumbsup:

is there not enough material. ? something casted different in that area too. have any pictures markus.....:thumbsup:

https://www.oldminibikes.com/forum/tecumseh/138509-hs40-revisions.html?highlight=hs40+differences

I think that Phil in NY was building one and had the case cut and rewelded to clear the aftermarket rod if I am not mistaken.