Bikes vibrates

- Thread starter aztec warrior

- Start date

- Tags bikes vibrates

I think the motor mount plate on them is a little on the thin side.

Actually, they are a LOT "on the thin side". They were made to accommodate the puny little Baja OEM engine. With the significant additional weight, HP and (especially) torque of the HF 6.5 HP engine that engine plate will flex. You need to reinforce that engine mount plate.

Michael

If you look at how the adapter mounts it does not allow full contact with the plate, they do not make anything better or easier except for engine installation. I have always re-slotted DBs rather than use those plates, I would never use one because I refuse to spend money to half ass mount an engine to an already compromised engine plate. The real culprit is the poor contact the plate makes with the frame, if it was welded down each side like vintage minis there would not be a problem even with the thickness.

If I had the facilities to do so I'd like to graft an engine mount setup used in Kart Racing onto a mini bike frame.

Ditch the slotted plate entirely and go with that utilize existing mounts etc. which are readily available. (as seen in example photo above) It would only require a little measurement for proper sprocket alignment and cutting, fitting and welding in the tubing for the mount to clamp onto. :grind:

Has anyone done that successfully before?

Ditch the slotted plate entirely and go with that utilize existing mounts etc. which are readily available. (as seen in example photo above) It would only require a little measurement for proper sprocket alignment and cutting, fitting and welding in the tubing for the mount to clamp onto. :grind:

Has anyone done that successfully before?

Well guys I am a fabricator so I could weld or make something...what do you guys suggest? Please post pics if you guys don't mind... Thanks in advance for all the replies...Martin

Michael

T-town I think I like the rubber spacer idea. Do you think I should incorporate the spacer plate that came with the conversion kit? if so how do you think I should do that?

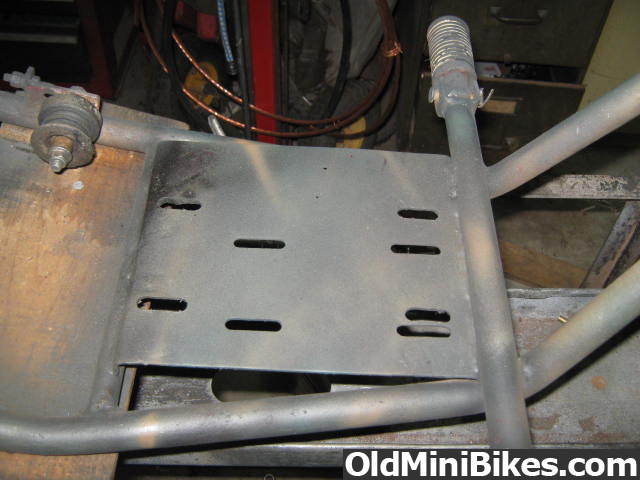

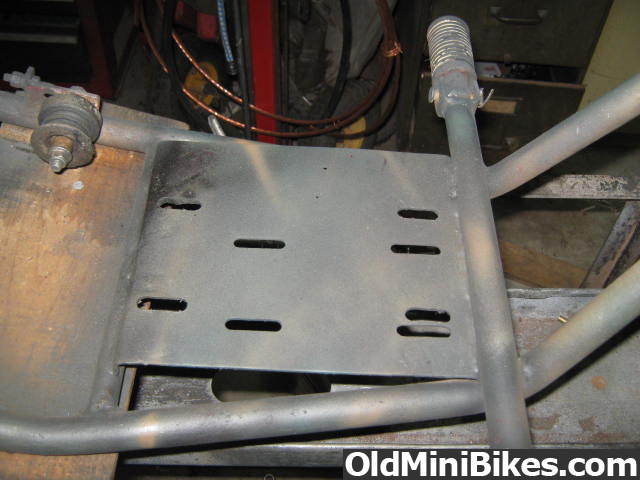

Never got to the gusseting but here's a pic of the re-slotted plate, I plan to make wedges to fill the gaps on my next one and weld em up then do what my buddy JDogg did across the bottom.

It's a new style DB but just the same plate. My first one was successful because I thought it out and made damn sure the chain was 100% in alignment with the clutch mounted inboard then I marked the edges of the engine and made a slot template the same size as the engine base then marked and slotted the plate. I have every confidence that you and most other members can do the same, I like doing things the hard way.

It's a new style DB but just the same plate. My first one was successful because I thought it out and made damn sure the chain was 100% in alignment with the clutch mounted inboard then I marked the edges of the engine and made a slot template the same size as the engine base then marked and slotted the plate. I have every confidence that you and most other members can do the same, I like doing things the hard way.

Outlaw how did you line up the sprocket on the back wheel to the clutch? I may have an idea but I wanna do it right...