Tecumseh Connecting Rods

- Thread starter roccosbike

- Start date

- Tags connecting rods tecumseh

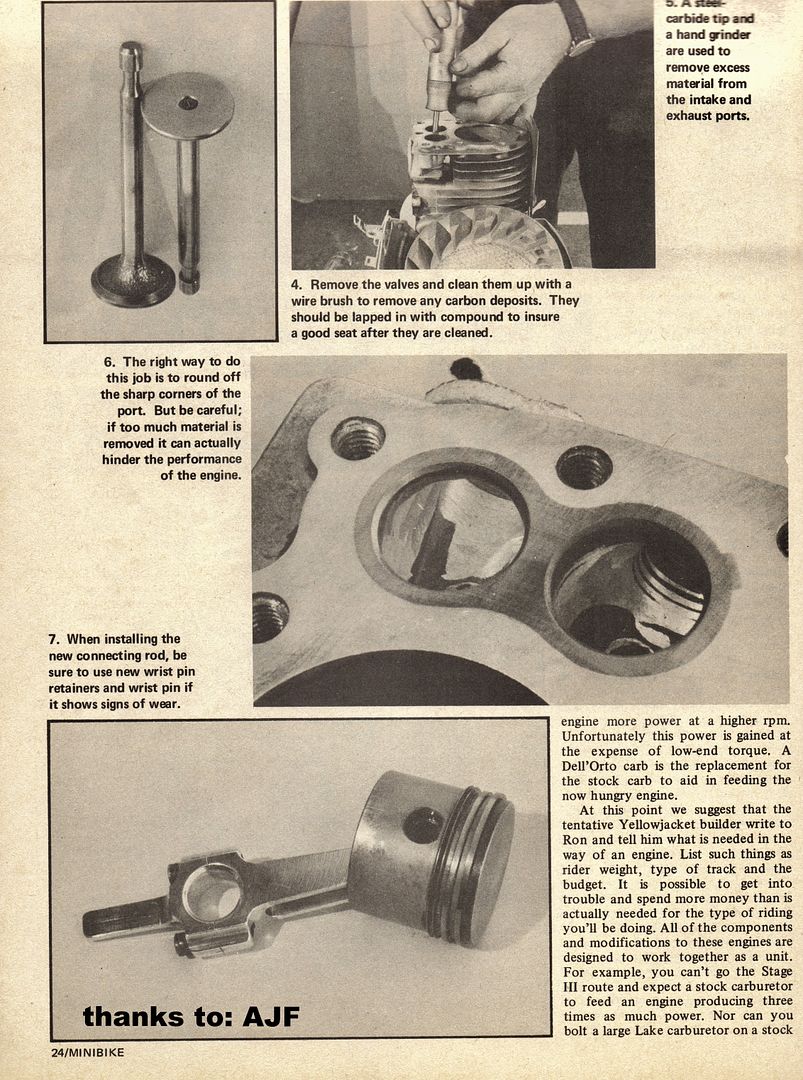

The rod I tried is a rod specific to the HS engines, not the OHV one with the dipper in the wrong spot, It was hitting the case I think even with the bolt out IIRC.

One of these rods:

Thats in a late model 80's H35 sidepopper I have, which came with large journal crank and HS rod factory (but still has the equal sized valves unlike the really late models where they shrunk the exhaust valve down).

If you compare an H engine and an HS you can see they added a little hump in the case on the HS, On the later H engine the hump still is not there. But the the stock HS style rod does clear, but not enough for the aftermarket rod. They may have altered that section slightly to give enough space on the later version but its not very noticeable if they did, I can't test an HS rod in the early small journal engine blocks due to not being able to get a crankshaft in there with the right size journal. So if you were going to go as far as boring out the flywheel side journal and use a larger journal sidecover on an early engine you may have a slight clearence problem at the face even with a stock rod to contend with as well.

And yes the one example Billet rod I was referring to was the one in that engine Karl had. that one was in an oil pump engine, so no dipper and had actual bearings, heres what the standard oil slinger looked like that Ron's used for the small frame H engines:

One of these rods:

Thats in a late model 80's H35 sidepopper I have, which came with large journal crank and HS rod factory (but still has the equal sized valves unlike the really late models where they shrunk the exhaust valve down).

If you compare an H engine and an HS you can see they added a little hump in the case on the HS, On the later H engine the hump still is not there. But the the stock HS style rod does clear, but not enough for the aftermarket rod. They may have altered that section slightly to give enough space on the later version but its not very noticeable if they did, I can't test an HS rod in the early small journal engine blocks due to not being able to get a crankshaft in there with the right size journal. So if you were going to go as far as boring out the flywheel side journal and use a larger journal sidecover on an early engine you may have a slight clearence problem at the face even with a stock rod to contend with as well.

And yes the one example Billet rod I was referring to was the one in that engine Karl had. that one was in an oil pump engine, so no dipper and had actual bearings, heres what the standard oil slinger looked like that Ron's used for the small frame H engines:

The engine I have is steel sleeved 2-1/2 bore and it has a compression release cam. The early Tecumseh Engines had smaller Journals with in my opinion very light weight connecting rods like in my H35 and now Yellow Jacket is long gone. I don't plan on trying to retrofit any other cranks or cams to my motor and it looks like I might just have to put it together with the stock rod too. I will take pics of the motor and post them up when its all done, I did make a pretty cool little down swept header for it too.

Thanks Delray and Markus This site is still just the Best there is!

Thanks Delray and Markus This site is still just the Best there is!

Last edited:

One engine im planning on hopping up in the future is a h35, I have so many in new/ old configurations.... the older ones had a smaller crankpin, slightly less displacement and points ignition. If you find someone willing make a quality, high performance small journal rod, ill take 5 for myself....

The engine I have is steel sleeved 2-1/2 bore and it has a compression release cam. The early Tecumseh Engines had smaller Journals with in my opinion very light weight connecting rods like in my H35 and now Yellow Jacket is long gone. I don't plan on trying to retrofit any other cranks or cams to my motor and it looks like I might just have to put it together with the stock rod too. I will take pics of the motor and post them up when its all done, I did make a pretty cool little down swept header for it too.

Thanks Delray and Markus This site is still just the Best there is!

Thanks Delray and Markus This site is still just the Best there is!

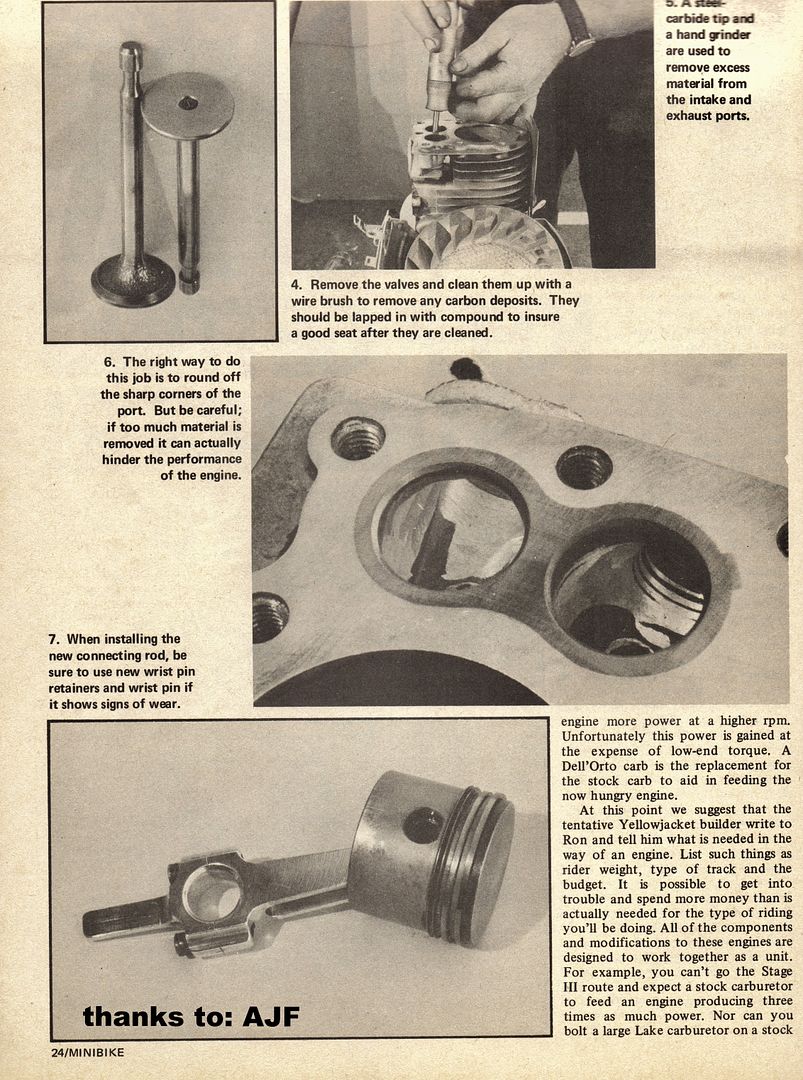

roccosbike,one thing you might want to do before assembling the motor. maybe polish rod beam.....:shrug: and also maybe hookup a tach and set the governor about 3600-3800 rpm's so you know your getting full power out of the governor and not over revving motor to the point the rod snap's on you.

i know i have had real good luck with my stock rod polish in a mild built ohh-motor. that engine turns just over 5000 rpm's

https://www.oldminibikes.com/forum/tecumseh/131688-tecumseh-ohh-build-5.html

LIKE them side poppers for sure:thumbsup:

i know i have had real good luck with my stock rod polish in a mild built ohh-motor. that engine turns just over 5000 rpm's

https://www.oldminibikes.com/forum/tecumseh/131688-tecumseh-ohh-build-5.html

LIKE them side poppers for sure:thumbsup:

The stock Tecumseh cast connecting rods can be improved to hold up for higher RPM, I can hold my early 70's HS40 engines wide open without breaking the rod, I never use a governor and have not broken any rods yet. I polish the outer beam on a de-burring wheel, any horizontal marks in outer surfaces of the rod can cause a failure so they must be removed, I also add a small oiling hole with a light counter sink to improve oiling. The picture below is from my current project 10 HP Tecumseh connecting rod it's been reworked. What I like about the stock rod is the cast aluminum is hard and resist wear, the HS40 version will out last the stock crank rod journal.

Tony

Tony

With regard to fasttony's post, I just did the same with the rods for my H60 builds. This is a link to the rod I used: Replacement Connecting Rod for Tecumseh V60 H60 TVM140 VH60 HH60

If the H35 rod offered by this vender is the same quality as the H60 rod, it would be plenty stout for 4000k. Really, really high quality casting with a thick web. Very little casting flash. Retired Factory Tecumseh rod is on left.

If the H35 rod offered by this vender is the same quality as the H60 rod, it would be plenty stout for 4000k. Really, really high quality casting with a thick web. Very little casting flash. Retired Factory Tecumseh rod is on left.

Last edited: