Hi all,

Putting a Sears Roper together and coming to the realization that the steering tube has been bent forwards, reducing the rake. Forks are straight (now) but when I put it all together there appears to be very little rake. The fork hits the steering tube when I turn the bars full left or right and it doesn't appear that the bars are turning as far as they should.

Looking at others pics I think the steering tube is bent.

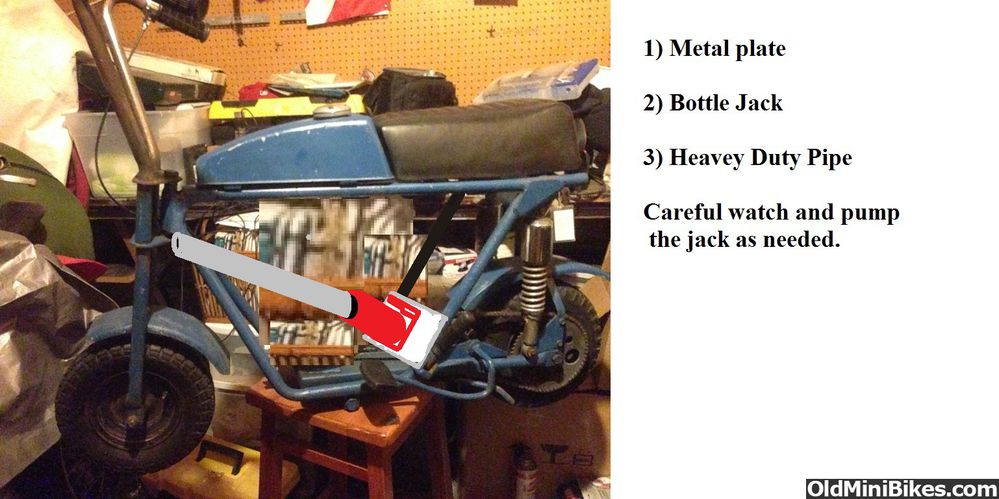

Soooo, should I cut it off and reweld it or stick a pipe in there, heat it and bend it out

or stick a pipe in there, heat it and bend it out

Thinking that the bending might deform the tube. But the cut and weld might be a tougher, more time intensive job (i got kids, a wife, and stuff-- time is GOLD).

Any advice?

Thanks

Putting a Sears Roper together and coming to the realization that the steering tube has been bent forwards, reducing the rake. Forks are straight (now) but when I put it all together there appears to be very little rake. The fork hits the steering tube when I turn the bars full left or right and it doesn't appear that the bars are turning as far as they should.

Looking at others pics I think the steering tube is bent.

Soooo, should I cut it off and reweld it

Thinking that the bending might deform the tube. But the cut and weld might be a tougher, more time intensive job (i got kids, a wife, and stuff-- time is GOLD).

Any advice?

Thanks