Thanks to everyone for your kind words :thumbsup:

My decals arrived today and they really finish off the restoration.

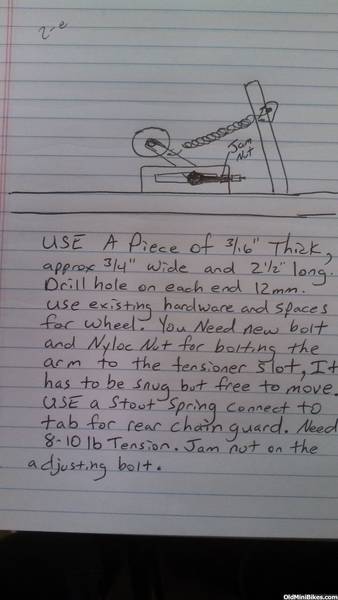

Tomorrow I need to figure out the chain tensioner, and line up the motor. Anyone got tips on marking out the engine holes for drilling?

I have not been updating this project because I've been sick, full of school work and generally busy. But I try and get as much time as I can in the garage. I can't wait to test ride this thing, so there's more motivation to get her done!

-Jackeo21

My decals arrived today and they really finish off the restoration.

Tomorrow I need to figure out the chain tensioner, and line up the motor. Anyone got tips on marking out the engine holes for drilling?

I have not been updating this project because I've been sick, full of school work and generally busy. But I try and get as much time as I can in the garage. I can't wait to test ride this thing, so there's more motivation to get her done!

-Jackeo21