Thanks Fantic Freddy.

Burnishing is like any other surface finish in that there are advantages or disadvantages to each. This process is for those of you who want a "fresh cast" appearance, but a little shinier. Polishing, painting, chroming, and anodizing, are all good in my book too.

Continuing from the same order. After a blast.

After burnishing. They look "alive" again.

See the reflection?

Burnishing is like any other surface finish in that there are advantages or disadvantages to each. This process is for those of you who want a "fresh cast" appearance, but a little shinier. Polishing, painting, chroming, and anodizing, are all good in my book too.

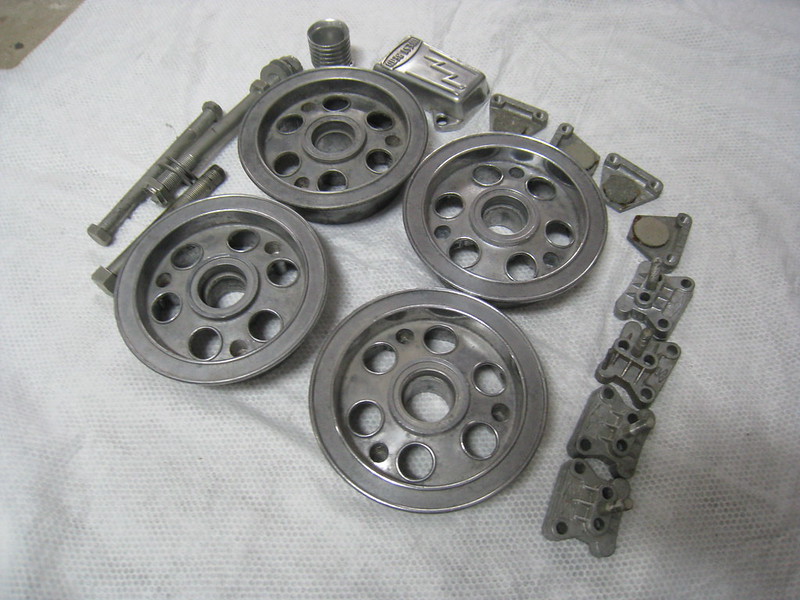

Continuing from the same order. After a blast.

After burnishing. They look "alive" again.

See the reflection?