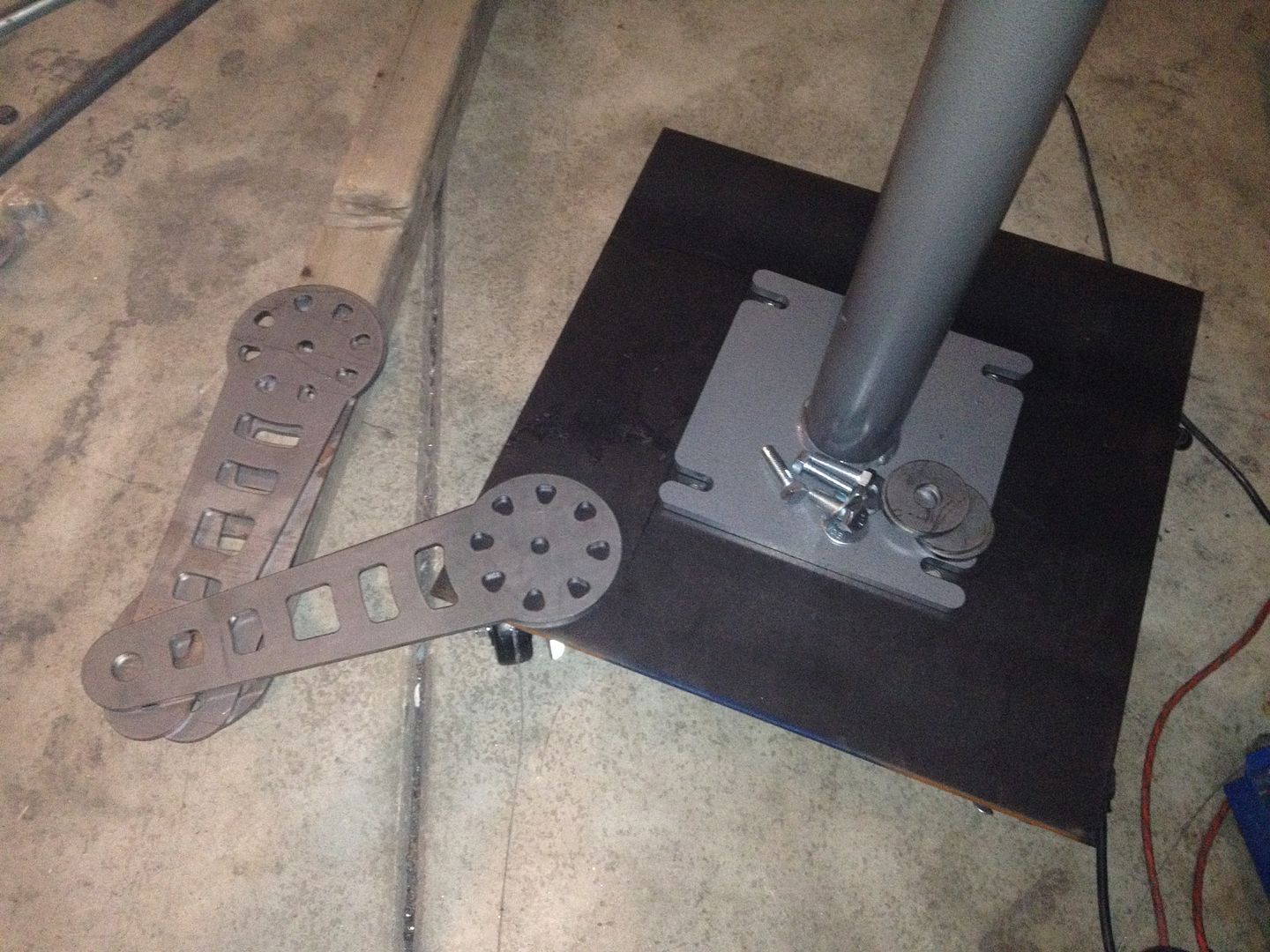

Just a mini project for my tubing bender (JD2 model 32)... its going to be hyd. but for now going to bend everything manually...

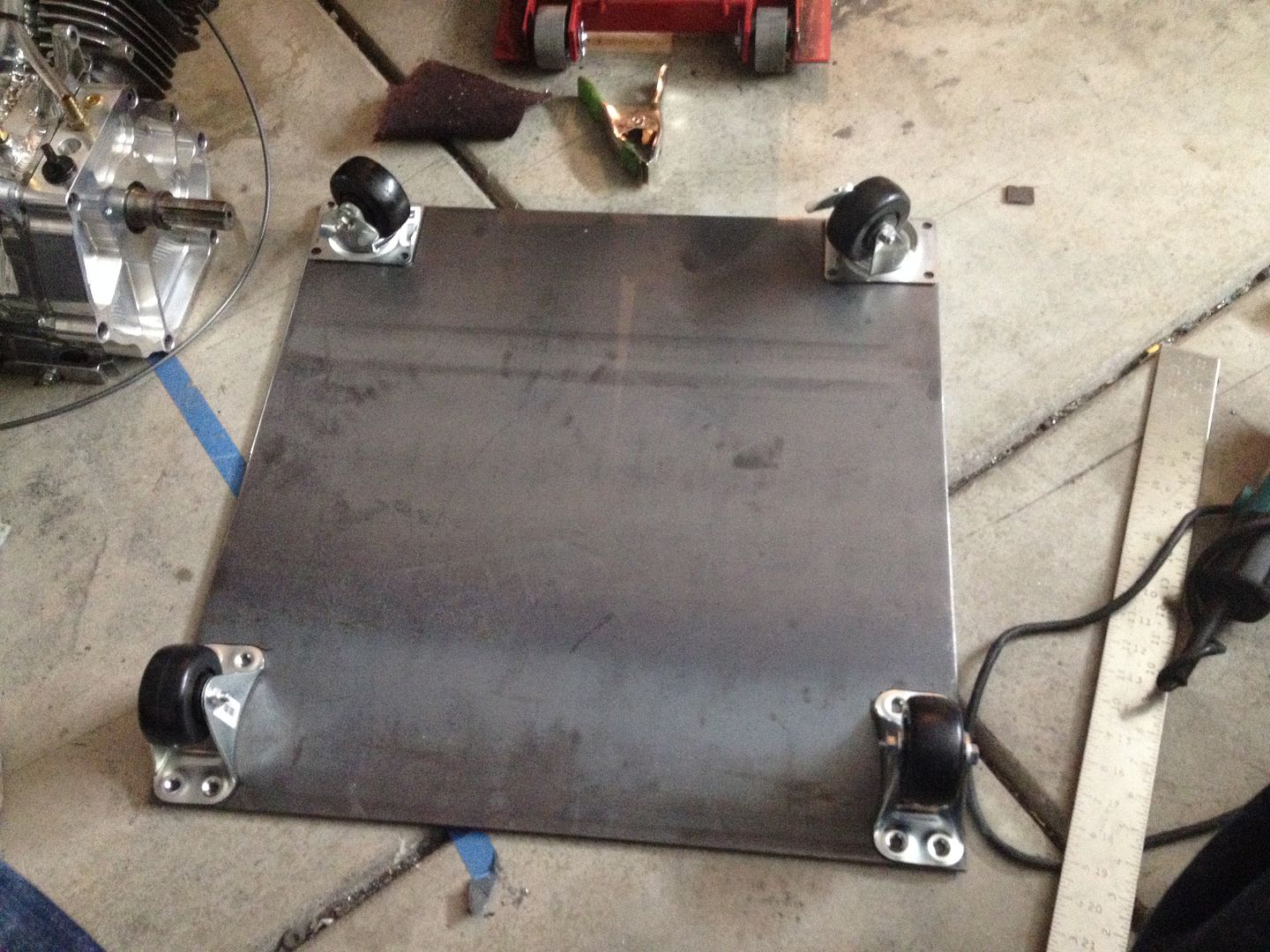

the way my garage is setup and constantly switching between projects, I dont have room to mount the bender in a fixed location... i decided to make a rolling platform for it.

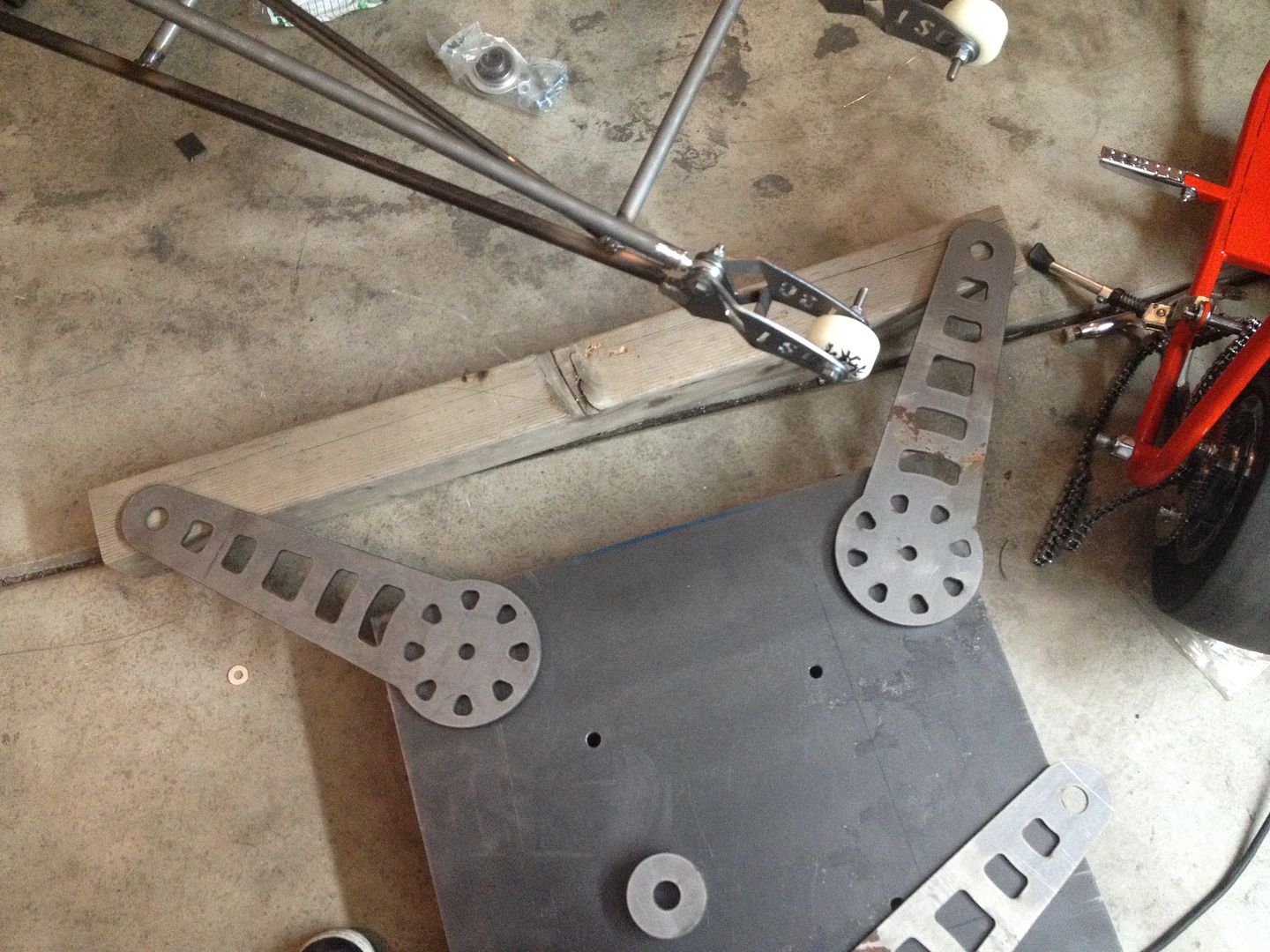

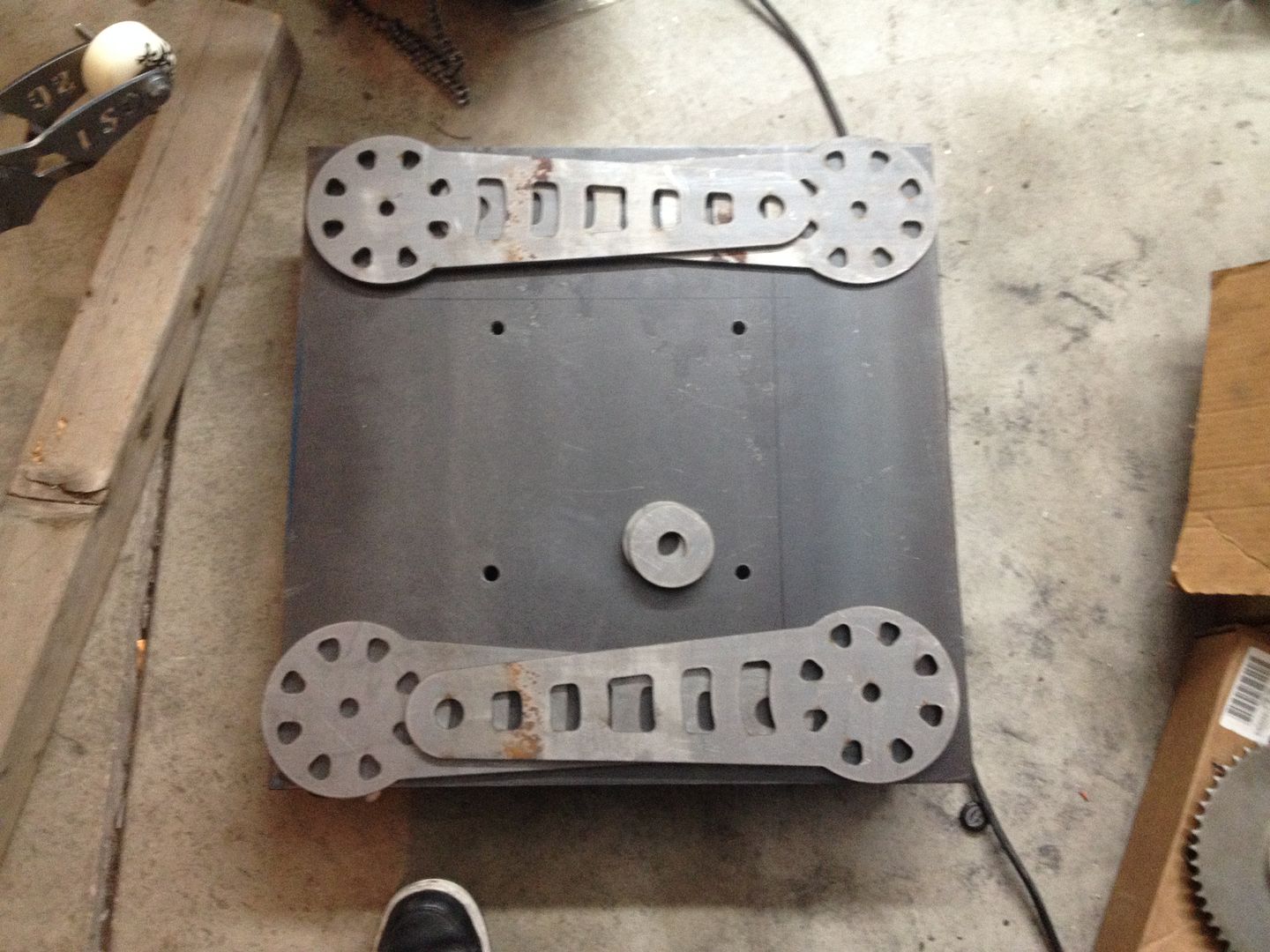

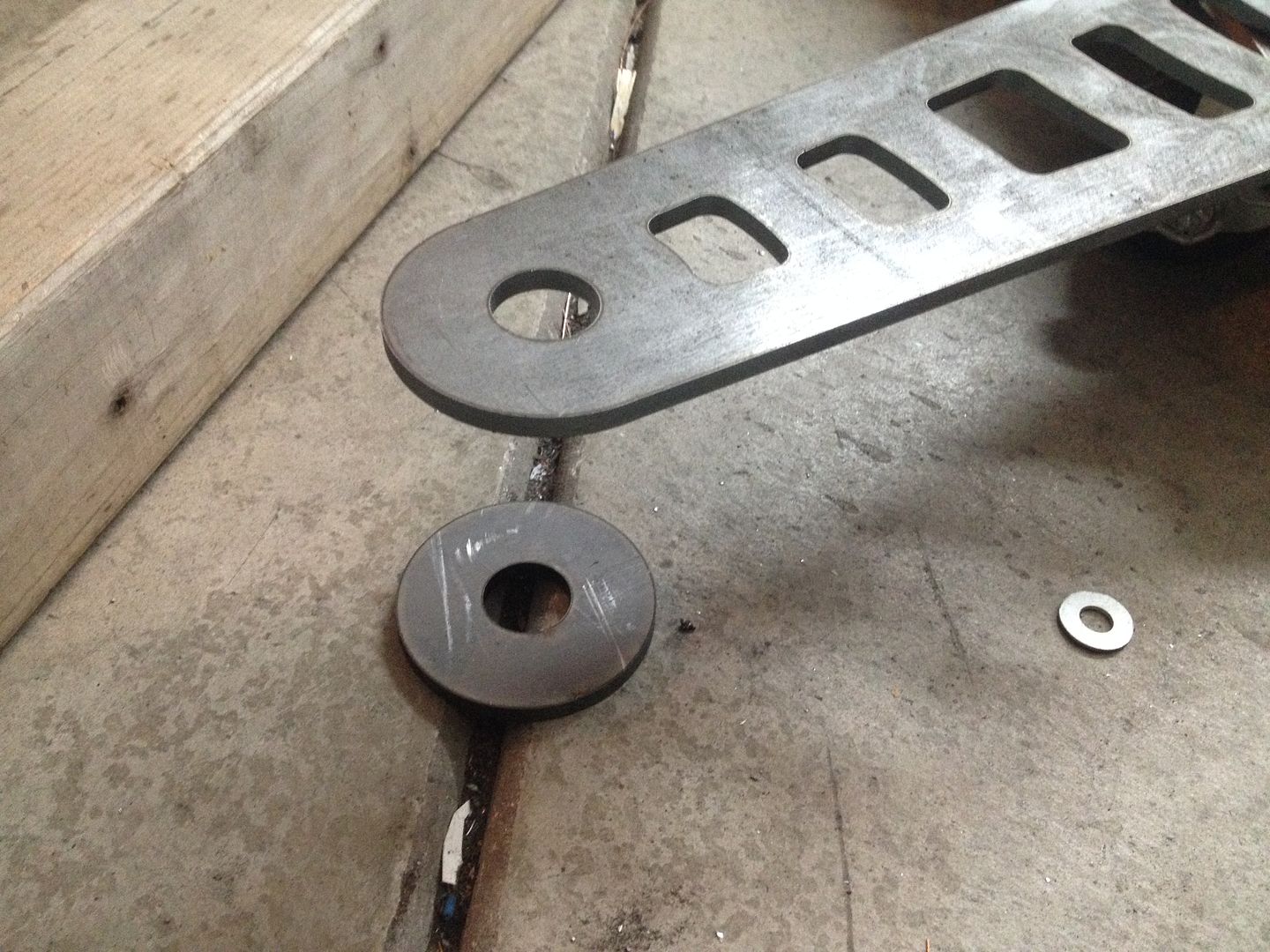

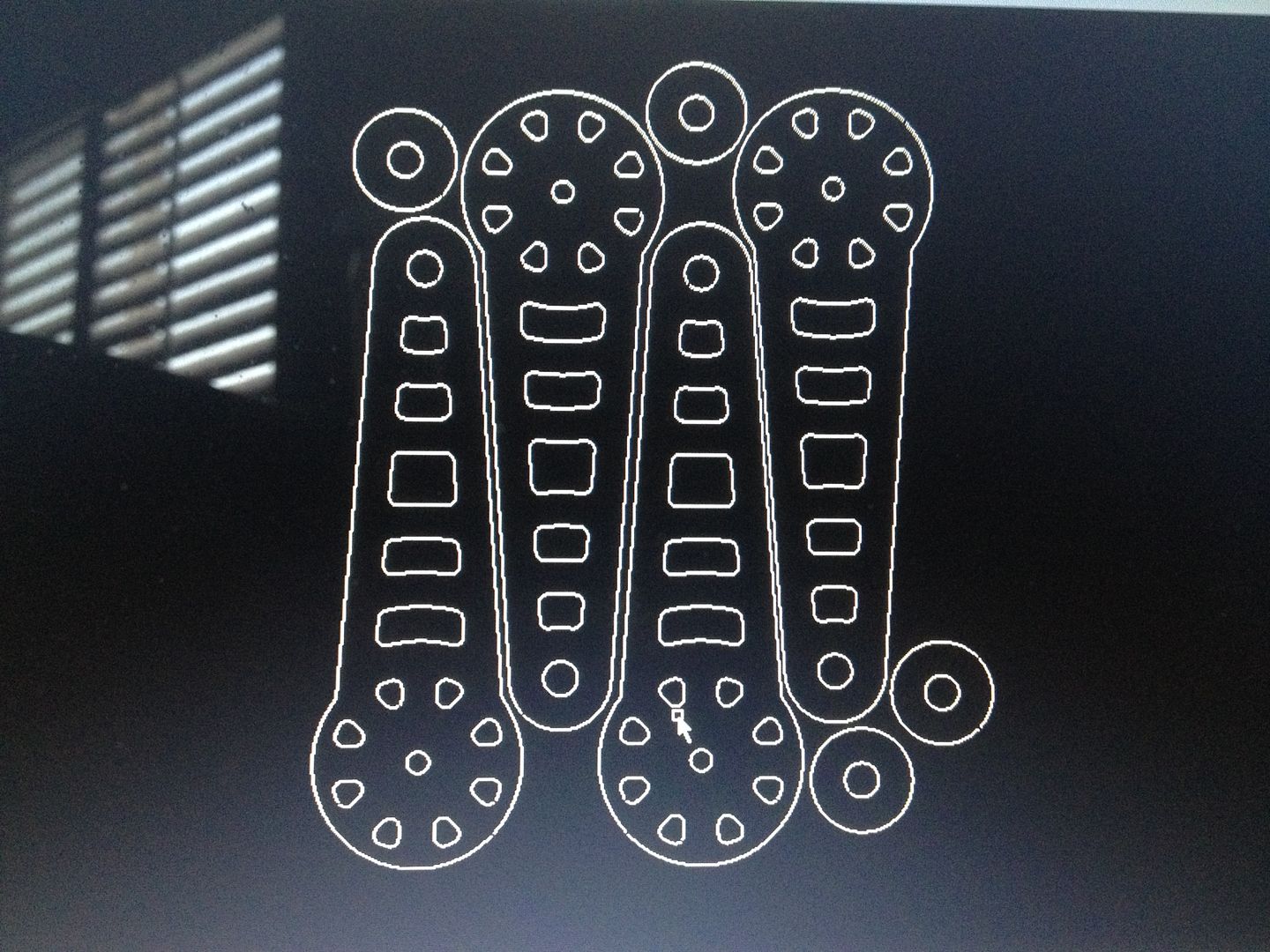

the main portion is 2' x 2' the legs are about 14.5" from center hole to hole... all 1/4" thick steel, but the legs will have 1/2' bracing on the bottom for extra strength, since i cut out the center to make it look better...

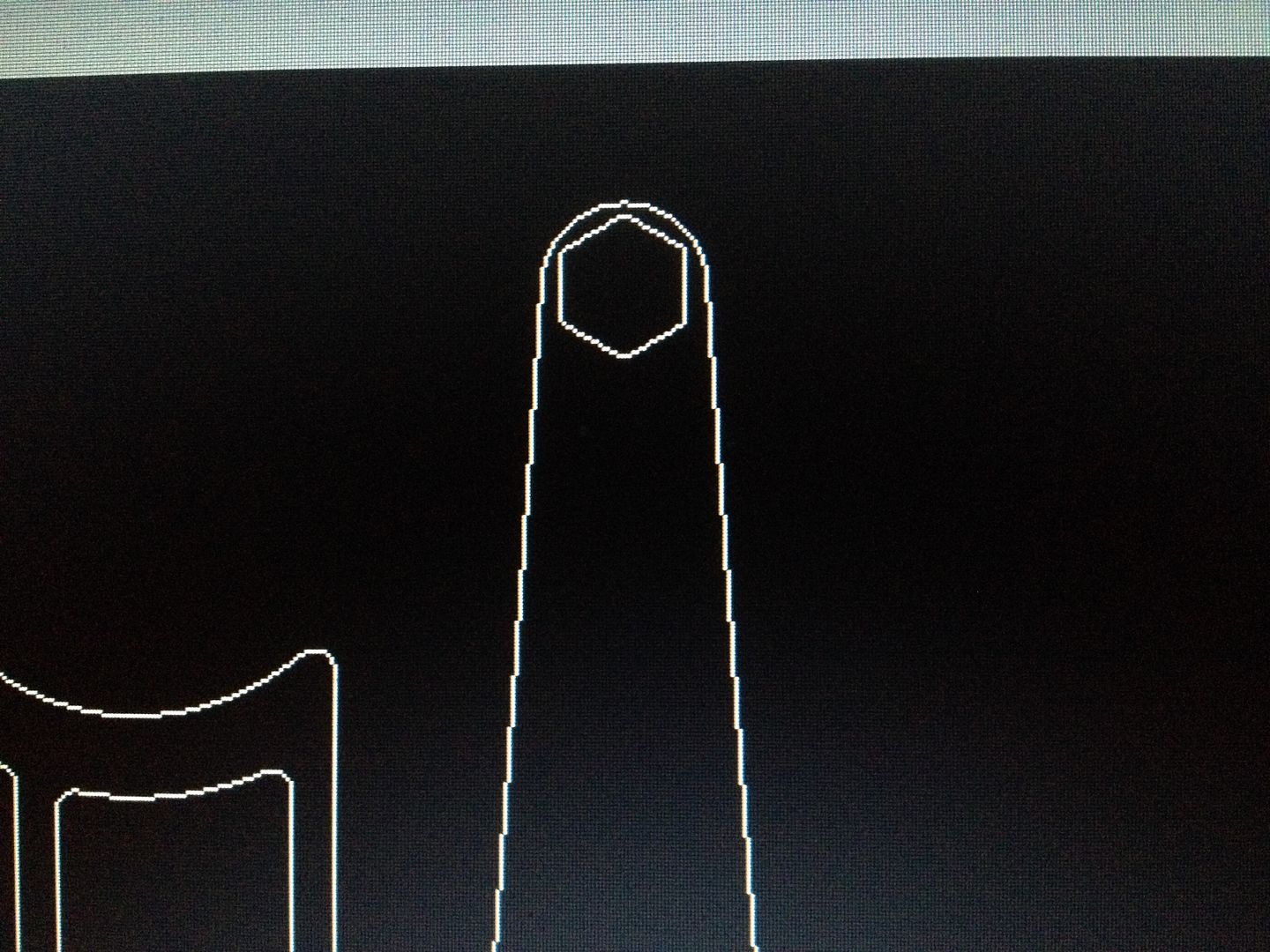

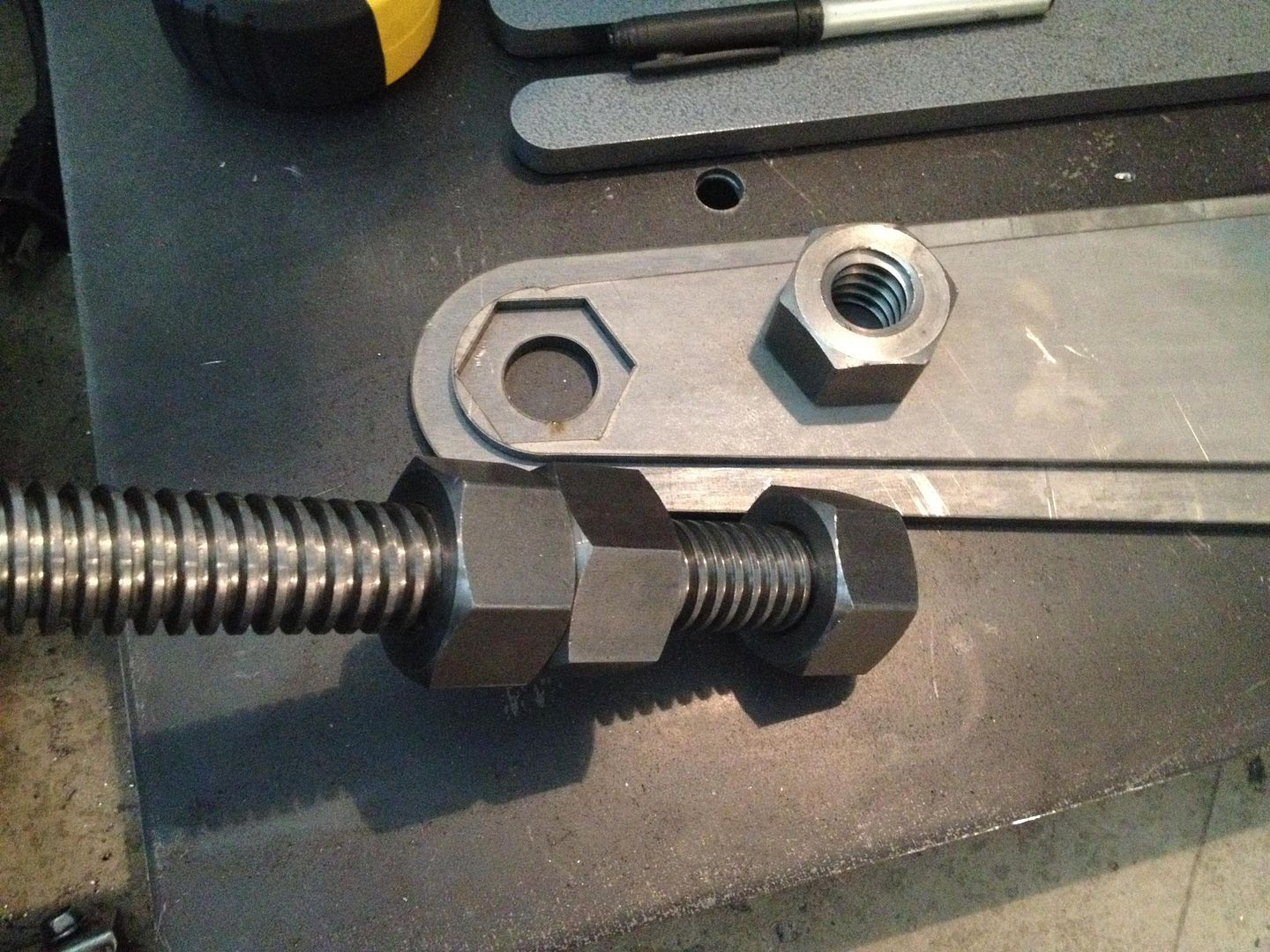

I am going to use 1" Acme thread rod for the adjustable feet... the feet will lift the platform slightly off the wheels and make it fully stable when im using it... the when not in use, can unbolt them, or swing them onto the platform to conserve space... will make more sense when im further ahead on it... hopefully...

will weld (nicely) a nut on top of the all thread so that the feet can easily be adjusted with a drill or i may make a crank for em or both... not sure just yet...

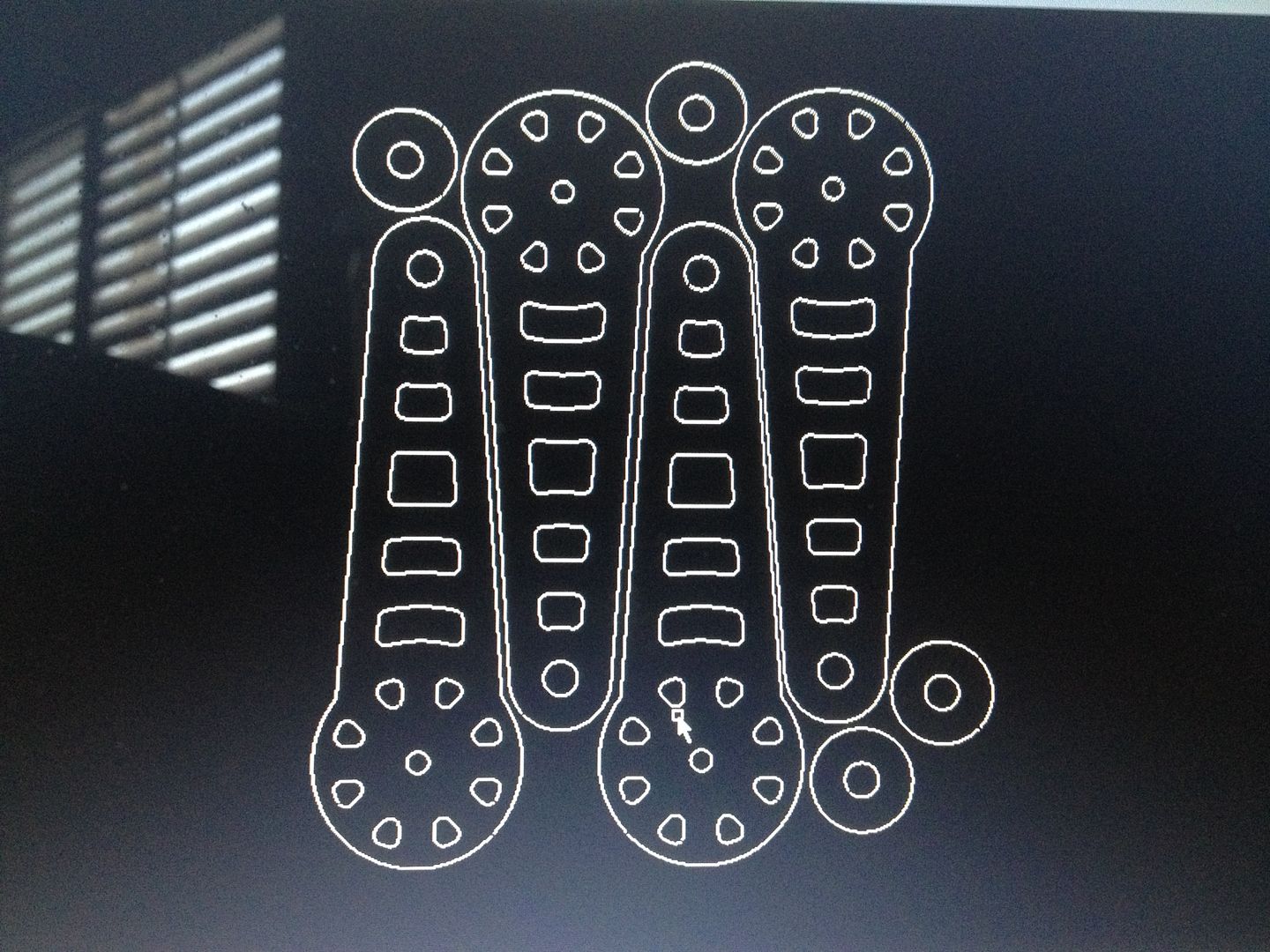

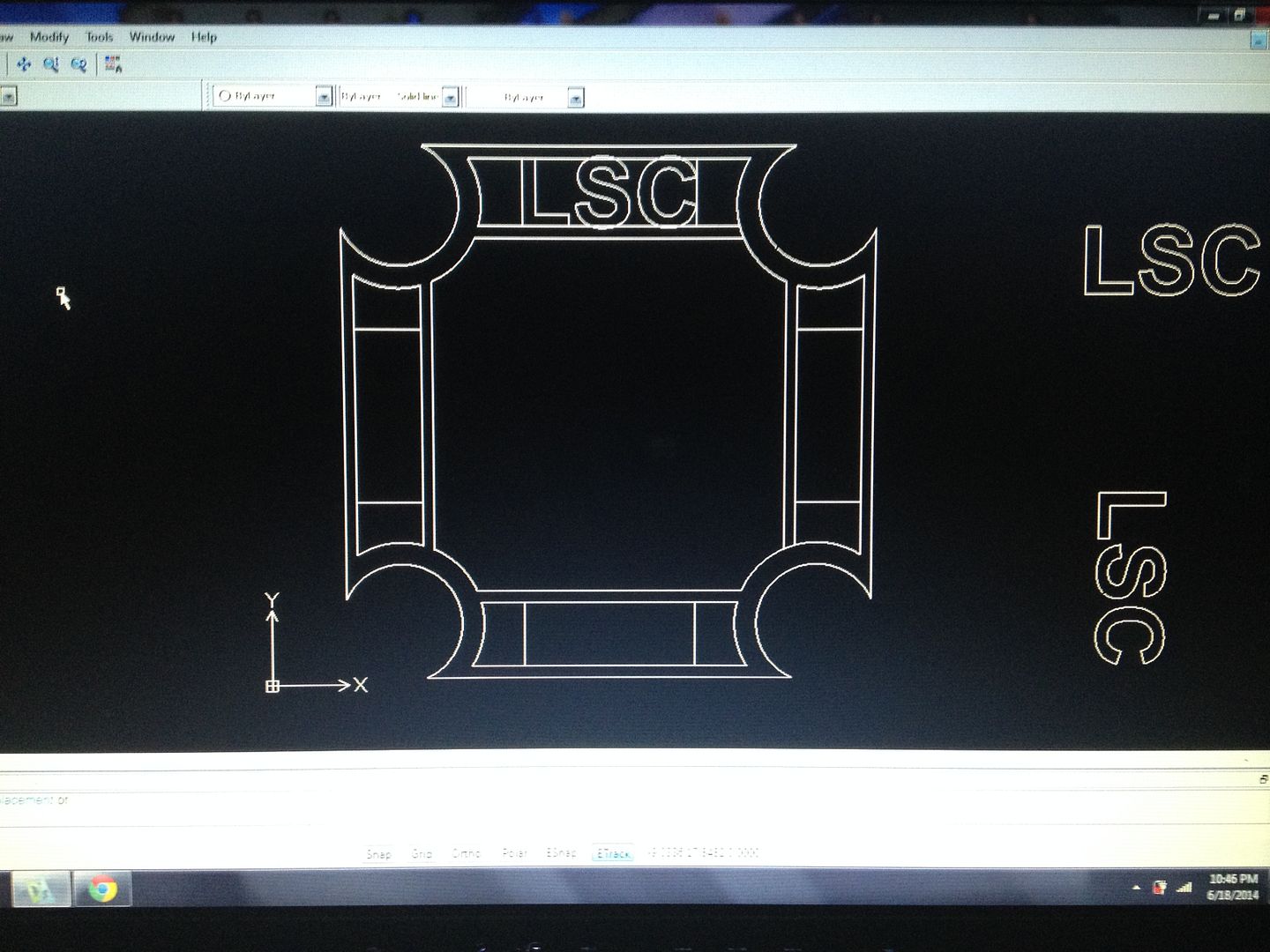

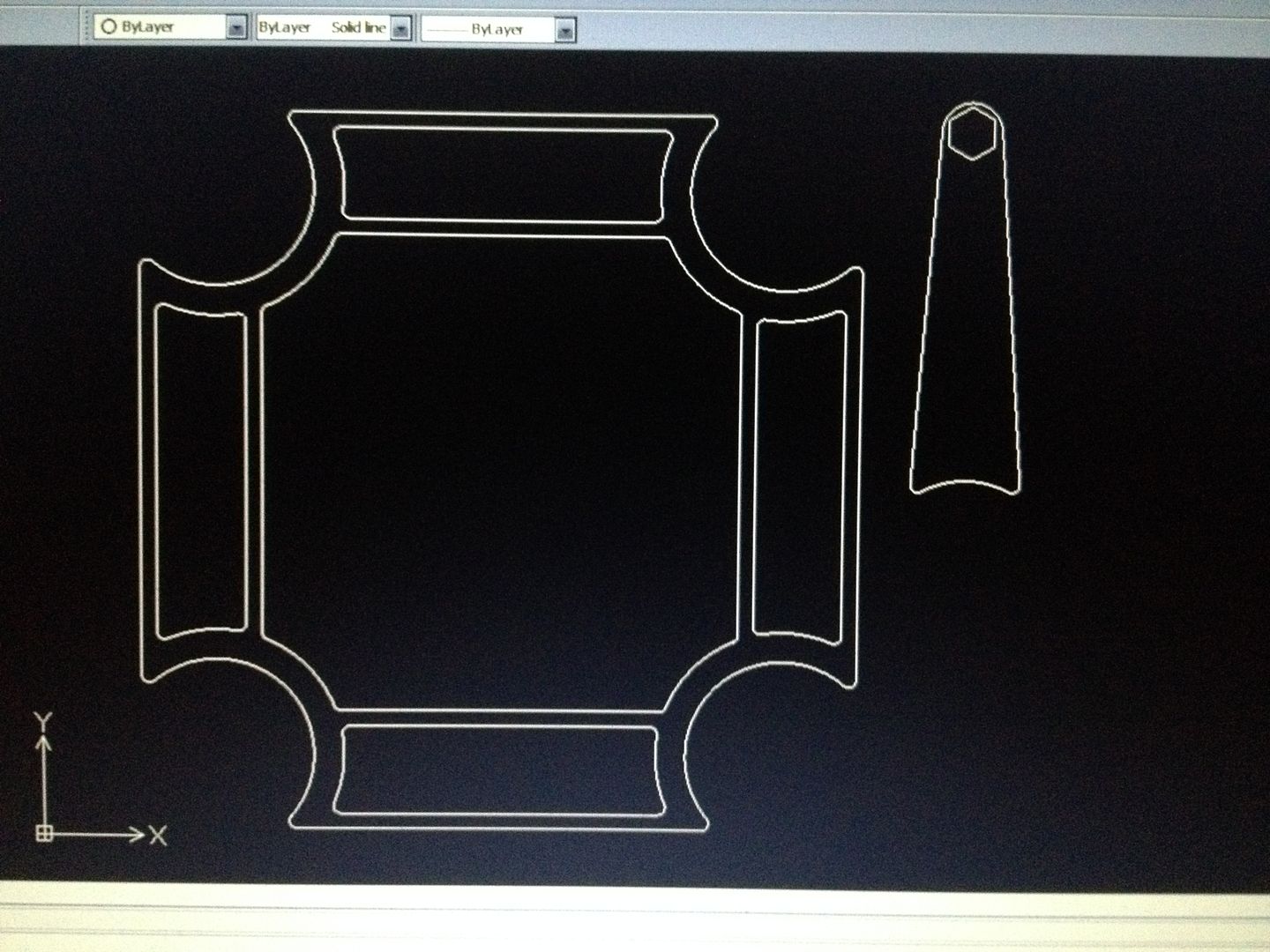

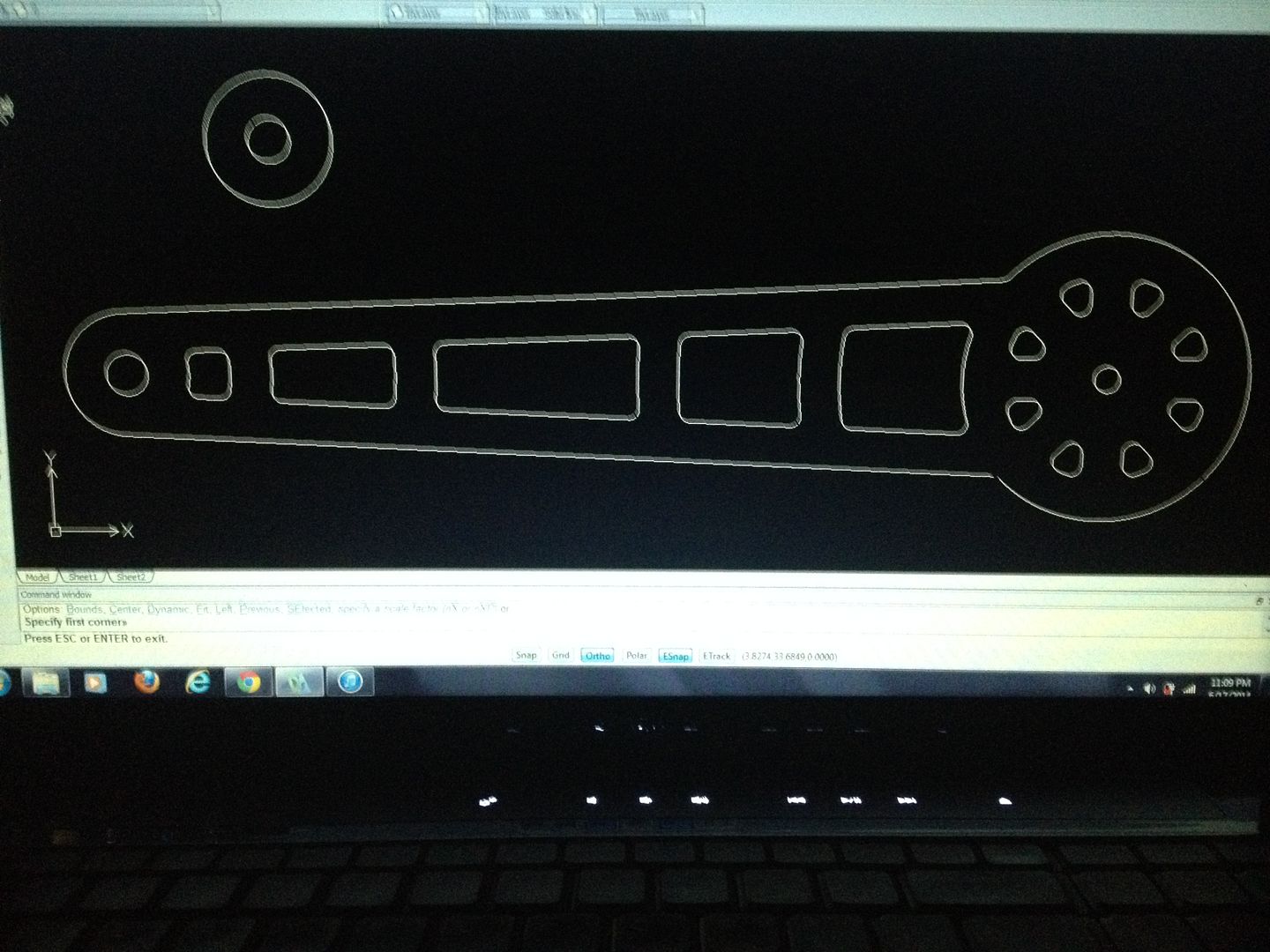

at first i drew the cad with longer legs, but went shorter because im only using 1/4" steel and i dont want it to flex...

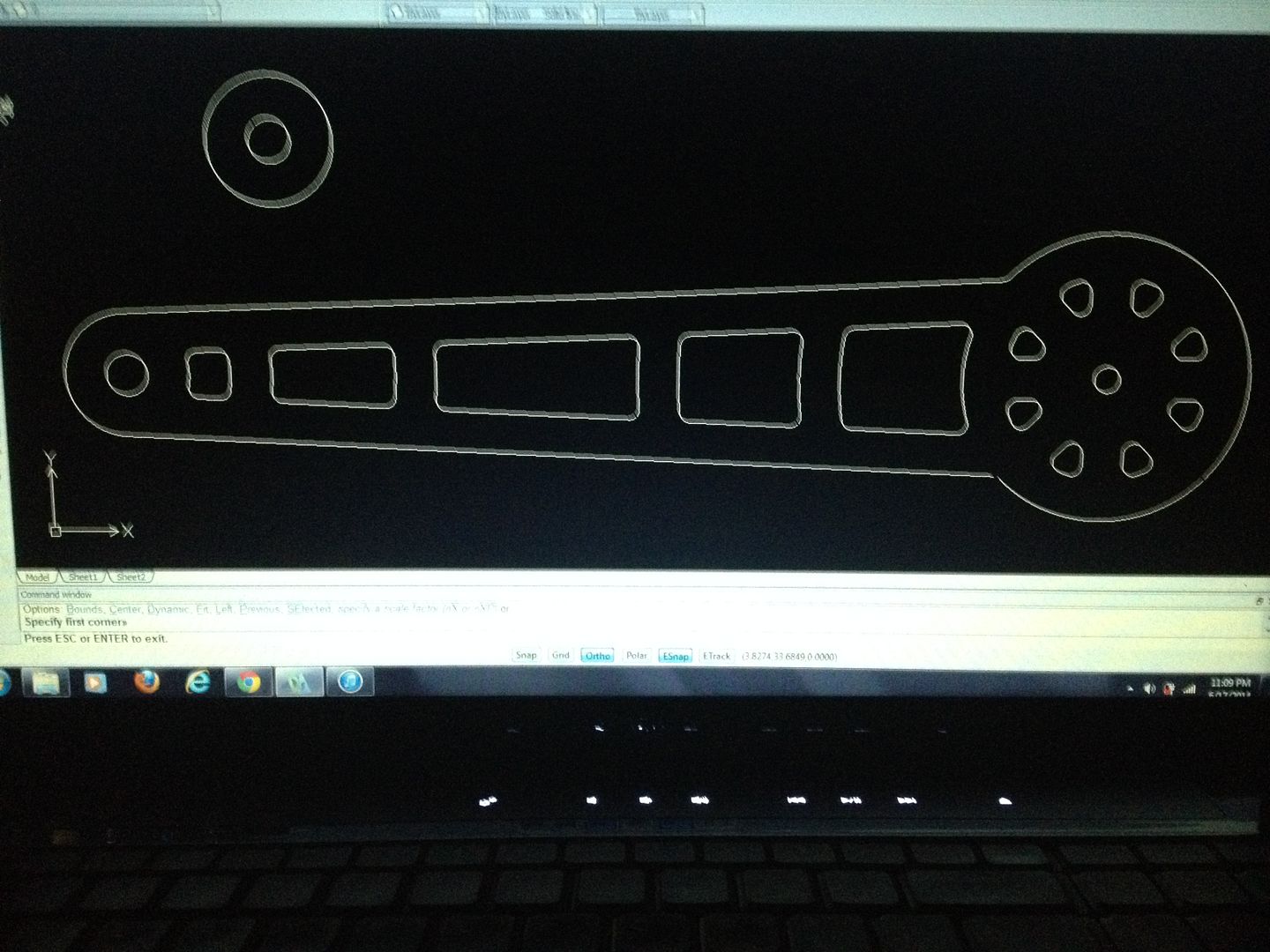

first cad drawing

final

the way my garage is setup and constantly switching between projects, I dont have room to mount the bender in a fixed location... i decided to make a rolling platform for it.

the main portion is 2' x 2' the legs are about 14.5" from center hole to hole... all 1/4" thick steel, but the legs will have 1/2' bracing on the bottom for extra strength, since i cut out the center to make it look better...

I am going to use 1" Acme thread rod for the adjustable feet... the feet will lift the platform slightly off the wheels and make it fully stable when im using it... the when not in use, can unbolt them, or swing them onto the platform to conserve space... will make more sense when im further ahead on it... hopefully...

will weld (nicely) a nut on top of the all thread so that the feet can easily be adjusted with a drill or i may make a crank for em or both... not sure just yet...

at first i drew the cad with longer legs, but went shorter because im only using 1/4" steel and i dont want it to flex...

first cad drawing

final