I have a Wards 525 that I recently purchased.

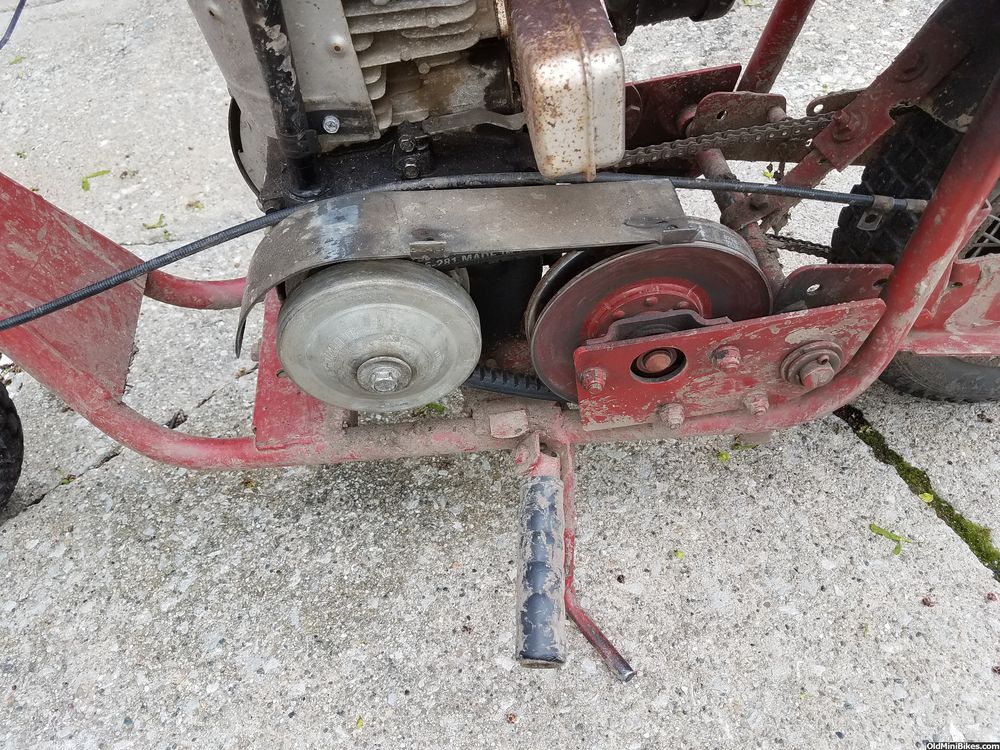

It runs and drives well but it doesn't have the correct drive system on it. It is just a clutch with a belt to a fixed pulley.

It works pretty good but I want more torque and lower "gearing" for acceleration. A torque converter gives that.

While researching I found they either cam with a two speed clutch or a torque converter.

I want to put a torque converter on mine. I'm not into 100% perfect OEM parts etc. I want function for not a lot of money.

It appears like a Comet 20 series type Torque converter set up would work better as opposed to a 30 series.

I say this because on a 30 series the driven spring is on the outside and on a 20 series it is on the inside.

I don't seem to have a lot of space to work with.

Please let me know what you think. Also if you have a picture of how Gilson/Wards did it from the factory that would be helpful. All the pictures I found had a clutch cover hiding what is behind it...

I have a generic plastic clutch cover I'll use for it...

Danford1

It runs and drives well but it doesn't have the correct drive system on it. It is just a clutch with a belt to a fixed pulley.

It works pretty good but I want more torque and lower "gearing" for acceleration. A torque converter gives that.

While researching I found they either cam with a two speed clutch or a torque converter.

I want to put a torque converter on mine. I'm not into 100% perfect OEM parts etc. I want function for not a lot of money.

It appears like a Comet 20 series type Torque converter set up would work better as opposed to a 30 series.

I say this because on a 30 series the driven spring is on the outside and on a 20 series it is on the inside.

I don't seem to have a lot of space to work with.

Please let me know what you think. Also if you have a picture of how Gilson/Wards did it from the factory that would be helpful. All the pictures I found had a clutch cover hiding what is behind it...

I have a generic plastic clutch cover I'll use for it...

Danford1