1971 Copper 5hp Briggs Rebuild

- Thread starter wmgatorfan08

- Start date

- Tags 1971 briggs copper rebuild

No not Briggs parts made in Tiawan.. But Looked real good to me and everything fit together nice..

Here is a pic of the parts I was able to paint today.

And here is a pic of the valve seats after I lapped them. There is still a lot of work to be done to the valve area. I just want to wait and see what the machine shop says about the cylinder and valve guides before I go any further with the block.

Well good news and bad news.

I had a set of standard rings laying around that I pulled out of another motor. They are still in really good shape. I put the top ring in the top and bottom of the cylinder and the gap between the ends of the ring was .035 on the feeler gauge. It fit snug on both the top and bottom measurements.

I had another block laying around that has a rough cylinder. I decided to see if I could hear the "pop" on the valves with it. I tried the intake first and there was definitely a "pop" sound. I could feel a big difference in the way the valve fit in the guide. So it looks like I am going to see how much the machine shop will charge to install new valve guides.

I am working on painting the gas tank right now! Coat 2 is drying!

I had a set of standard rings laying around that I pulled out of another motor. They are still in really good shape. I put the top ring in the top and bottom of the cylinder and the gap between the ends of the ring was .035 on the feeler gauge. It fit snug on both the top and bottom measurements.

I had another block laying around that has a rough cylinder. I decided to see if I could hear the "pop" on the valves with it. I tried the intake first and there was definitely a "pop" sound. I could feel a big difference in the way the valve fit in the guide. So it looks like I am going to see how much the machine shop will charge to install new valve guides.

I am working on painting the gas tank right now! Coat 2 is drying!

What is the "good " news"? A ring gap of .035" is just a hair before "reject" size as per Briggs specs, and indicates a worn cylinder wall...:shrug:

A ring gap of .035" is just a hair before "reject" size as per Briggs specs, and indicates a worn cylinder wall...:shrug:

Michael

Michael

Anyways Im taking the block to the shop today for them to check it out.

To measure ring gap you have to use NEW, or near- new rings. While measuring the ring gap is a useful tool to get a ROUGH idea of cylinder wall wear, it does not come anywhere close to telling the whole story. That is to say, it will not tell you if the cylinder wall is worn tapered or out-of-round. For that you need to measure the cylinder bore at 6 locations ( 2 high, 2 middle, and 2 low) using a telescoping bore gauge and transfer those readings to a micrometer. Briggs provides "reject" sizes for all of those measurements in their repair manual.

Michael

Michael

To measure ring gap you have to use NEW, or near- new rings. While measuring the ring gap is a useful tool to get a ROUGH idea of cylinder wall wear, it does not come anywhere close to telling the whole story. That is to say, it will not tell you if the cylinder wall is worn tapered or out-of-round. For that you need to measure the cylinder bore at 6 locations ( 2 high, 2 middle, and 2 low) using a telescoping bore gauge and transfer those readings to a micrometer. Briggs provides "reject" sizes for all of those measurements in their repair manual.

Michael

Michael

Well took the block to the machine shop and they said it would be about 100 dollars to install new valve guides, do a complete valve job, and bore it 20 over. But they are really busy and said it could be over a month before they could touch it

Also the muffler I ordered came in but it is too small. I could have sworn I looked up the part number before I ordered. Anyways I guess Im gonna hvae to look for a new muffler. The seller I got it from does not accept returns.

Going to be posting a wanted add for a good block.

Also the muffler I ordered came in but it is too small. I could have sworn I looked up the part number before I ordered. Anyways I guess Im gonna hvae to look for a new muffler. The seller I got it from does not accept returns.

Going to be posting a wanted add for a good block.

Ok so still not sure what to do about the block. I have been looking at this one on ebay for a few days.

(#1)BRIGGS 5HP BLOCK-ALUMINUM BORE .003" OVERSZIE OLD STYLE 2 BOLT PORTS | eBay

What do you guys think?? I talked to the guy and he said that it was .003 out of round from top to bottom.

(#1)BRIGGS 5HP BLOCK-ALUMINUM BORE .003" OVERSZIE OLD STYLE 2 BOLT PORTS | eBay

What do you guys think?? I talked to the guy and he said that it was .003 out of round from top to bottom.

If he is saying the cylinder bore is .003" out of round then it's past reject size. On Briggs aluminum blocks, or lightweight blocks, reject size for out of round is .0025". In his ad description and title he states this block is .003" bored over. If he meant to tell you it's .003" over standard then you could use the Briggs chrome ring set to control any possible oil consumption. These won't require honing or glaze breaking the bore to seat. However, be advised that .003" over standard is on the brink of a worn out bore.

His whole ad sounds fishy to me. If you're still interested in the block you better get clarification if the block is .003" out of round or .003" bored over standard. Also it's imperative you ask about the mag journal size and condition. Reject size for the mag journal is .8726". Who knows the valve seats, guides, and cam journal could be worn as well. You need to ask the seller about these before even considering purchasing.

If I were you I would stay away from this one. IMO it looks like the block is old and you can see rust all over the bare metal parts. I have worked on blocks that have been sitting outside for probably 25-30+ years and dated back to 1965 and never seen one with that much rust build up. His whole ad sounds and looks fishy. You'll need to ask him about any concerns you have.

If you haven't already, it would be of a great interest to you to invest in a Briggs and Stratton Repair manual. The only way to go when rebuilding these small engines.

His whole ad sounds fishy to me. If you're still interested in the block you better get clarification if the block is .003" out of round or .003" bored over standard. Also it's imperative you ask about the mag journal size and condition. Reject size for the mag journal is .8726". Who knows the valve seats, guides, and cam journal could be worn as well. You need to ask the seller about these before even considering purchasing.

If I were you I would stay away from this one. IMO it looks like the block is old and you can see rust all over the bare metal parts. I have worked on blocks that have been sitting outside for probably 25-30+ years and dated back to 1965 and never seen one with that much rust build up. His whole ad sounds and looks fishy. You'll need to ask him about any concerns you have.

If you haven't already, it would be of a great interest to you to invest in a Briggs and Stratton Repair manual. The only way to go when rebuilding these small engines.

Last edited:

If he is saying the cylinder bore is .003" out of round then it's past reject size. On Briggs aluminum blocks, or lightweight blocks, reject size for out of round is .0025". In his ad description and title he states this block is .003" bored over. If he meant to tell you it's .003" over standard then you could use the Briggs chrome ring set to control any possible oil consumption. These won't require honing or glaze breaking the bore to seat. However, be advised that .003" over standard is on the brink of a worn out bore.

His whole ad sounds fishy to me. If you're still interested in the block you better get clarification if the block is .003" out of round or .003" bored over standard. Also it's imperative you ask about the mag journal size and condition. Reject size for the mag journal is .8726". Who knows the valve seats, guides, and cam journal could be worn as well. You need to ask the seller about these before even considering purchasing.

If I were you I would stay away from this one. IMO it looks like the block is old and you can see rust all over the bare metal parts. I have worked on blocks that have been sitting outside for probably 25-30+ years and dated back to 1965 and never seen one with that much rust build up. His whole ad sounds and looks fishy. You'll need to ask him about any concerns you have.

If you haven't already, it would be of a great interest to you to invest in a Briggs and Stratton Repair manual. The only way to go when rebuilding these small engines.

His whole ad sounds fishy to me. If you're still interested in the block you better get clarification if the block is .003" out of round or .003" bored over standard. Also it's imperative you ask about the mag journal size and condition. Reject size for the mag journal is .8726". Who knows the valve seats, guides, and cam journal could be worn as well. You need to ask the seller about these before even considering purchasing.

If I were you I would stay away from this one. IMO it looks like the block is old and you can see rust all over the bare metal parts. I have worked on blocks that have been sitting outside for probably 25-30+ years and dated back to 1965 and never seen one with that much rust build up. His whole ad sounds and looks fishy. You'll need to ask him about any concerns you have.

If you haven't already, it would be of a great interest to you to invest in a Briggs and Stratton Repair manual. The only way to go when rebuilding these small engines.

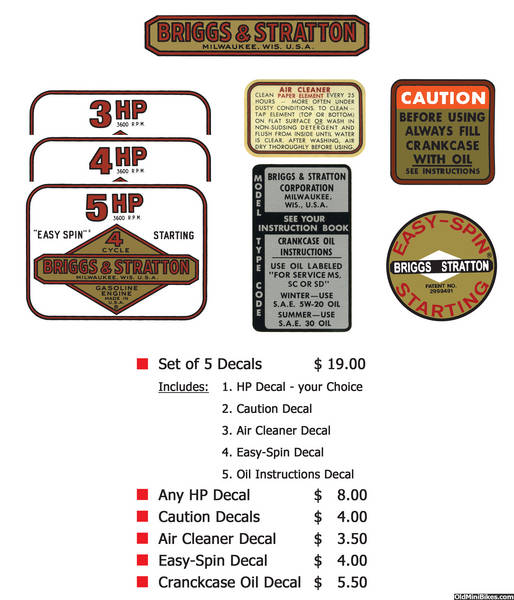

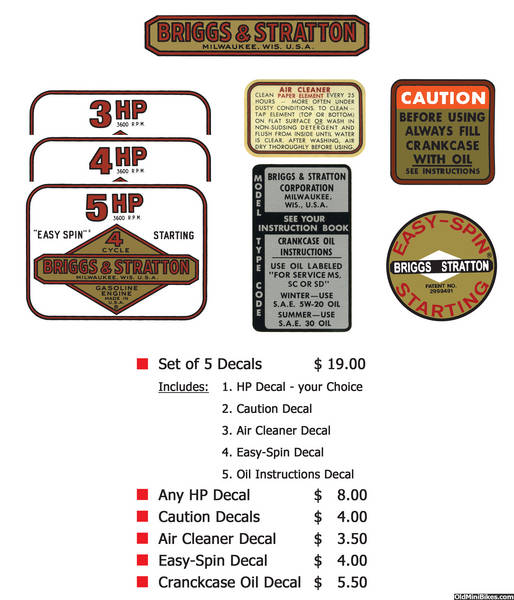

Restoration "Must Haves"

There is for one thing you will absolutely need if in fact you are going to do a proper restoration, and all the experts agree -

Minibike Paul WATER TRANSFER DECALS!

Available at decal, Minibike Paul Home ,mailed same day!!

.

There is for one thing you will absolutely need if in fact you are going to do a proper restoration, and all the experts agree -

Minibike Paul WATER TRANSFER DECALS!

Available at decal, Minibike Paul Home ,mailed same day!!

.

The Ruppster is exactly correct. On these old engines it is not (only) just about cylinder wall scoring and if it smokes or not. As Jeff mentioned, there are other very important tolerances to check that Briggs refers to as "reject sizes" in their repair manuals, any of which could be "deal breakers" as they are generally not cost effective to repair/replace. If you are going to start restoring/rebuilding/refurbishing old Briggs engines do yourself a favor and purchase a manual or two so YOU have the specs. There are some great deals on EBay (I've seen NOS manuals for as low as $ 5.00 + shipping).

Michael

Michael