Reproduction Throttle * FREE*

- Thread starter Joe51

- Start date

- Tags free* reproduction throttle

I'm just reading this thread. I would like to input some information. In your picture, the spring is in a different place than the one I have had in the garage. The only reason I know this is because I just sold it and took a picture of it. I never looked at it before. :smile: I hope this helps out.

...so when you back off the throttle instead of slowing down it goes wide open....:scared:

know wonder we haven't heard from Mark....:laugh:

know wonder we haven't heard from Mark....:laugh:

Ok, first off there are two slightly different versions of this HS linkage, and two different springs. There is the one that Joe made, it has a notch on the actuating arm for the early style spring and a flat part where the cable stop goes. The other spring will also fit this style.

Joes part:

OEM on a HS40- notice how the spring fits into the "notch"

Here is the other style on a HS50- notice the curved part where the cable stop goes, also no notch.

Here is a side view (sorry for the crappy pic)

So there are the two different springs, the one that came with Joes linkage will fit both actuating arms, but spring that fits into the notched arm will not fit on the one without. Make sense?

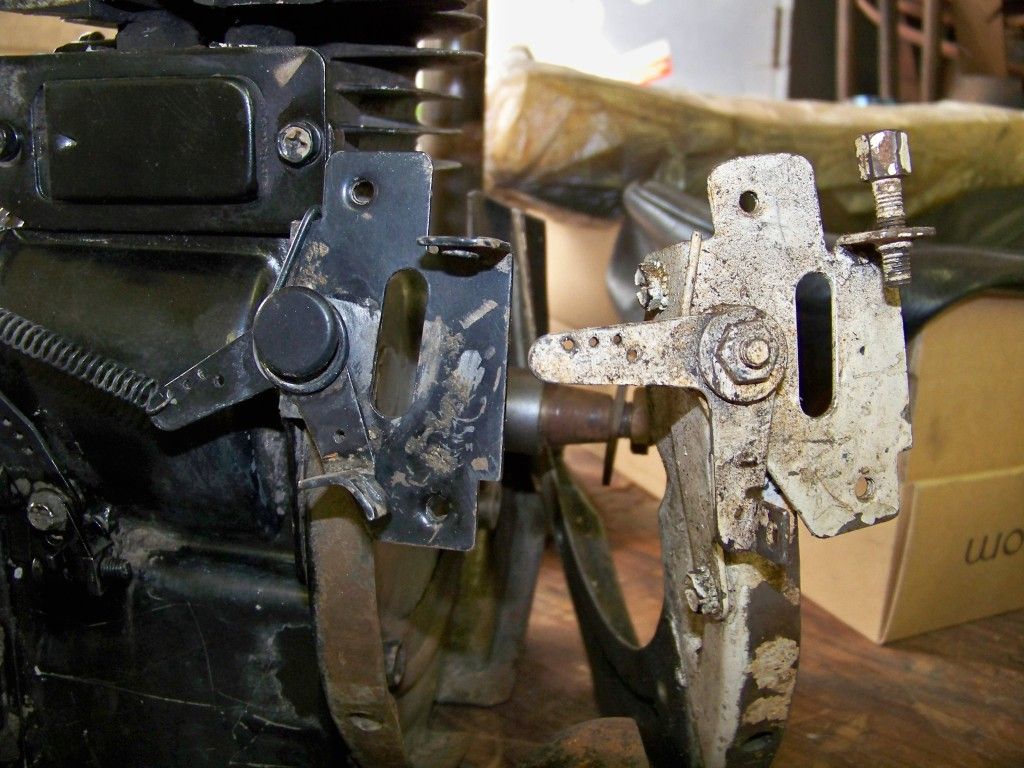

So on to the test subject. I chose to use my Ruttman for a few reasons, one being that the engine originally came on a snow blower, and I had modified that linkage to work. Functional, but ugly:laugh:

So this is what I started with- look how the arm travels in an arc, but the cable is in a fixed position. It worked OK, but it was always a little sticky.

Installation is fairly straightforward. First remove the two side bolts

Then the three headbolts that secure the cover to the block. (you may have to loosen the front headbolts as well if there is a mounted gas tank like mine)

From there we remove the blower housing and now can access the rivets that hold the old linkage on. Good thing is you can drill them out using a 3/16" bit, and you don't have to remove the flywheel:thumbsup:. Some engines have this part bolted on, so you don't even have to remove the cover.

I like to use a little cutting oil and a nice sharp bit, makes all the difference.

Make sure you clean up the shavings IMMEDIATELY after you drill. You don't want this stiff getting stuck to your flywheel magnets.

:thumbsup:

Here is the old ugly, next to the new nice one:thumbsup:

Installation was a breeze, I just put a couple of pop rivets in from the back side.

Like most of you, my old throttle cable was actually a bicycle brake cable. Now was the perfect time to change it out. I was got ahold of some actual throttle wire (it has finer strands, so it is more flexible) and got some quality cable with a liner inside. A little lube, and it pulls smooth as silk:thumbsup:, way better than that old one.

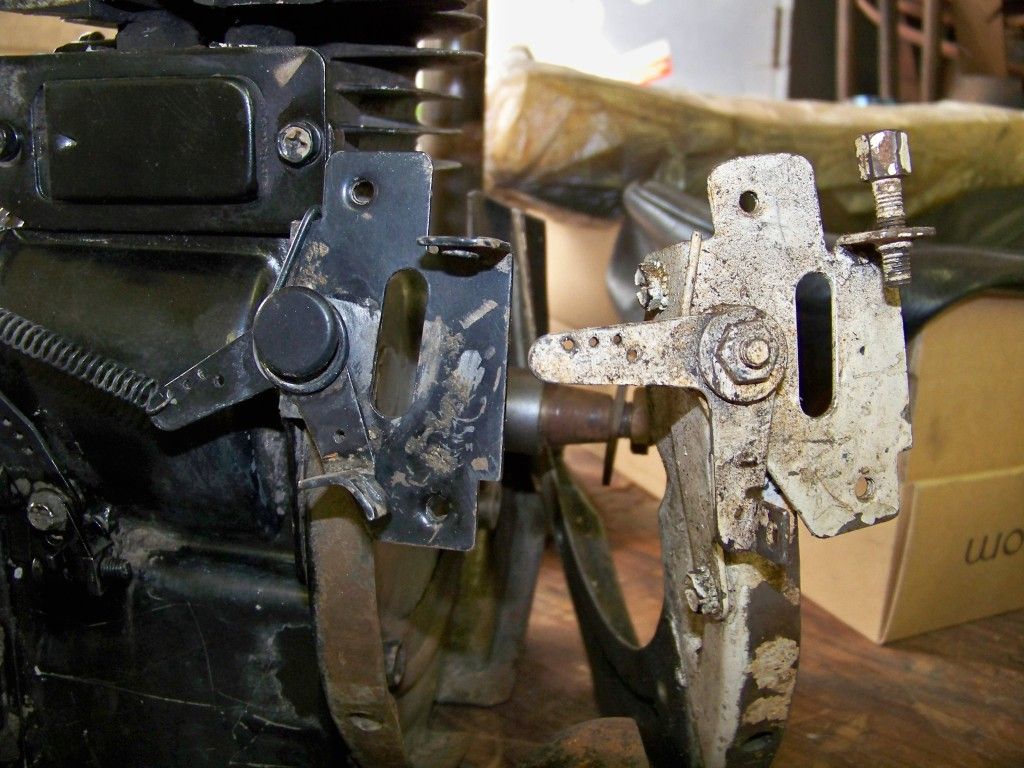

Here we are all mounted up. The old spring was quite a bit longer, so I just robbed a short one from one of my other motors. (I could have just cut the old one down and that would have worked fine too). I still have to trim the cable back a bit and put an end on it so it doesn't fray. Notice on the actuating arm where the cable goes through is slotted, this allows for the cable to move as the arm travels upward. Way better than my modified snowblower part, now the movement is nice and smooth with no binding whatsoever.

After a little ride time I give this a big thumbs up, I still have to fiddle with my governor adjustment but as far as throttle control, it works flawlessly:thumbsup:

If you are lucky enough to get your hands on one of these you will not be disappointed, it looks and functions EXACTLY like OEM.

Thanks again Joe!!!!!

So this is what I started with- look how the arm travels in an arc, but the cable is in a fixed position. It worked OK, but it was always a little sticky.

Installation is fairly straightforward. First remove the two side bolts

Then the three headbolts that secure the cover to the block. (you may have to loosen the front headbolts as well if there is a mounted gas tank like mine)

From there we remove the blower housing and now can access the rivets that hold the old linkage on. Good thing is you can drill them out using a 3/16" bit, and you don't have to remove the flywheel:thumbsup:. Some engines have this part bolted on, so you don't even have to remove the cover.

I like to use a little cutting oil and a nice sharp bit, makes all the difference.

Make sure you clean up the shavings IMMEDIATELY after you drill. You don't want this stiff getting stuck to your flywheel magnets.

:thumbsup:

Here is the old ugly, next to the new nice one:thumbsup:

Installation was a breeze, I just put a couple of pop rivets in from the back side.

Like most of you, my old throttle cable was actually a bicycle brake cable. Now was the perfect time to change it out. I was got ahold of some actual throttle wire (it has finer strands, so it is more flexible) and got some quality cable with a liner inside. A little lube, and it pulls smooth as silk:thumbsup:, way better than that old one.

Here we are all mounted up. The old spring was quite a bit longer, so I just robbed a short one from one of my other motors. (I could have just cut the old one down and that would have worked fine too). I still have to trim the cable back a bit and put an end on it so it doesn't fray. Notice on the actuating arm where the cable goes through is slotted, this allows for the cable to move as the arm travels upward. Way better than my modified snowblower part, now the movement is nice and smooth with no binding whatsoever.

After a little ride time I give this a big thumbs up, I still have to fiddle with my governor adjustment but as far as throttle control, it works flawlessly:thumbsup:

If you are lucky enough to get your hands on one of these you will not be disappointed, it looks and functions EXACTLY like OEM.

Thanks again Joe!!!!!